FRONT AXLE

M6060, M7060, WSM

5-S17

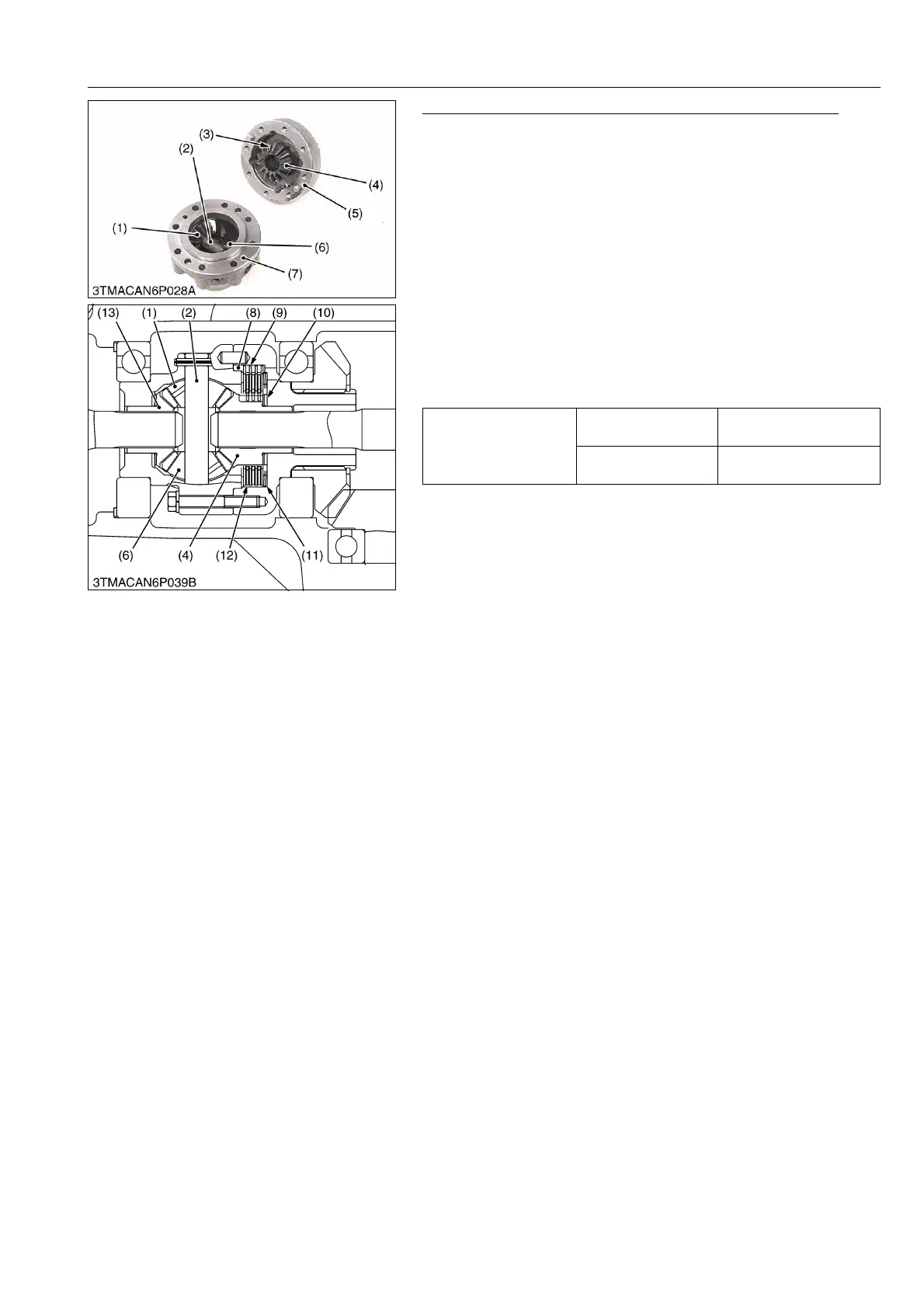

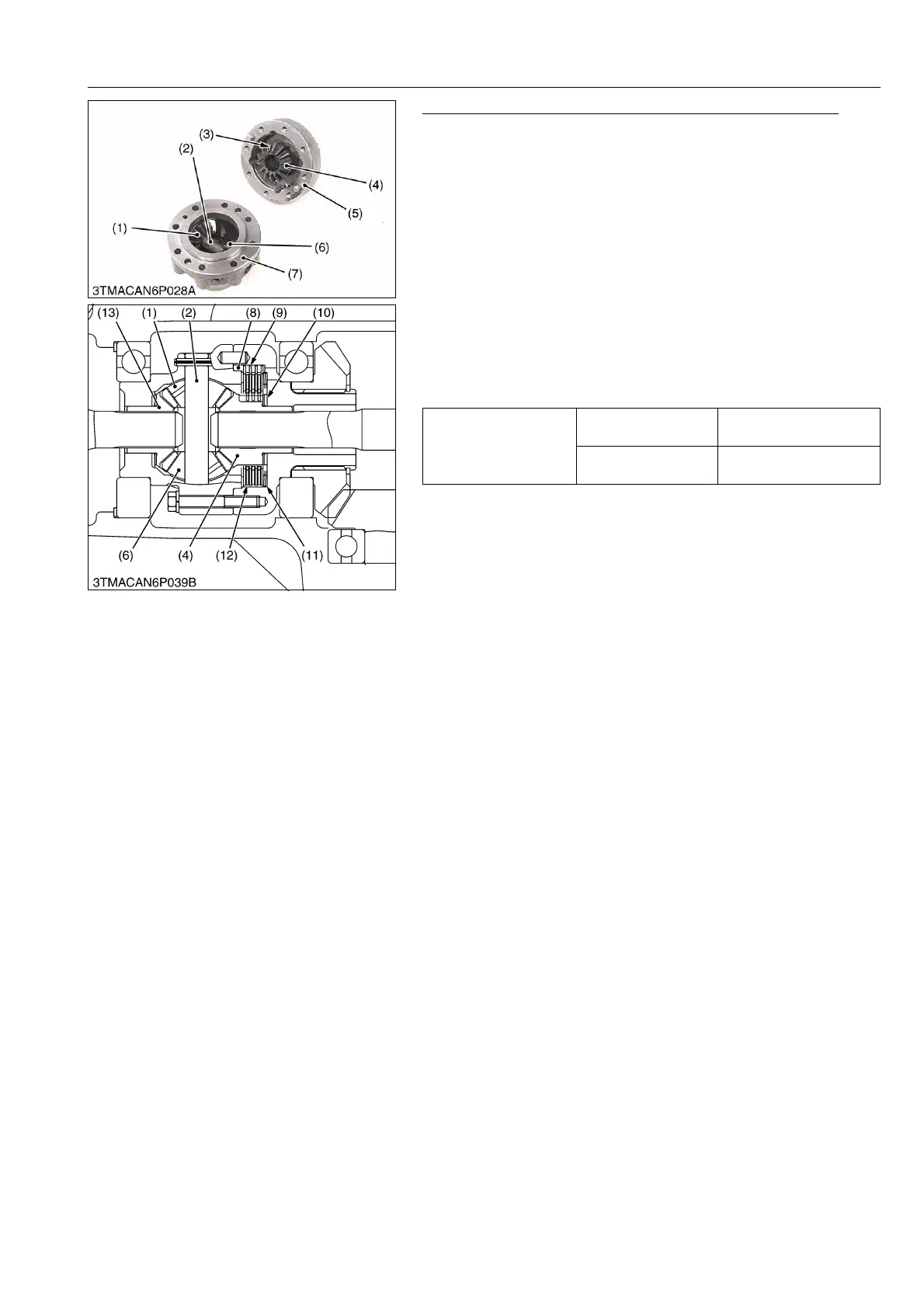

Backlash between Differential Pinion and LSD Side Gear

1. Assemble the pinion gear (1), (6) and pinion shaft (2) without

differential side gear (13).

2. Assemble the LSD side gear (4) without belleville washers

(cupped spring washer) (11), steel plates (9), LSD disks (12)

and LSD shim (8).

3. Put the plastigauge (wire of solder) (3) on the LSD side gear (4).

4. Assemble the differential case (7) and differential case cover

(5).

5. Turn the LSD side gear using the yoke shaft to clash the

plastigauge (wire of solder).

6. Disassemble the differential case cover and measure the

thickness of plastigauge (wire of solder).

7. If the backlash exceeds the allowable limit, adjust with shim

(10).

8. Adjust the backlash properly by repeated above procedure.

(Reference)

• Thickness of adjusting shim :

0.8 mm (0.032 in.) [Code No. 67211-15170]

1.0 mm (0.039 in.) [Code No. 67211-15160]

1.2 mm (0.047 in.) [Code No. 67211-15180]

• Standard size of shim : 1.0 mm (0.039 in.)

9Y1210828FAS0029US0

Backlash between pinion

gear and LSD side gear

Factory specification

0.1 to 0.3 mm

0.004 to 0.01 in.

Allowable limit

0.4 mm

0.02 in.

(1) Pinion Gear

(2) Pinion Shaft

(3) Plastigauge (Wire of Solder)

(4) Side Gear (LSD)

(5) Differential Case Cover

(6) Pinion Gear

(7) Differential Case

(8) Shim (LSD)

(9) Steel Plate

(10) Shim (LSD Side Gear)

(11) Belleville Washer (Cupped Spring

Washer)

(12) LSD Disk

(13) Side Gear

Loading...

Loading...