8.8 Manual Tuning

8.8.2 Feedforward

8-41

8.8.2

Feedforward

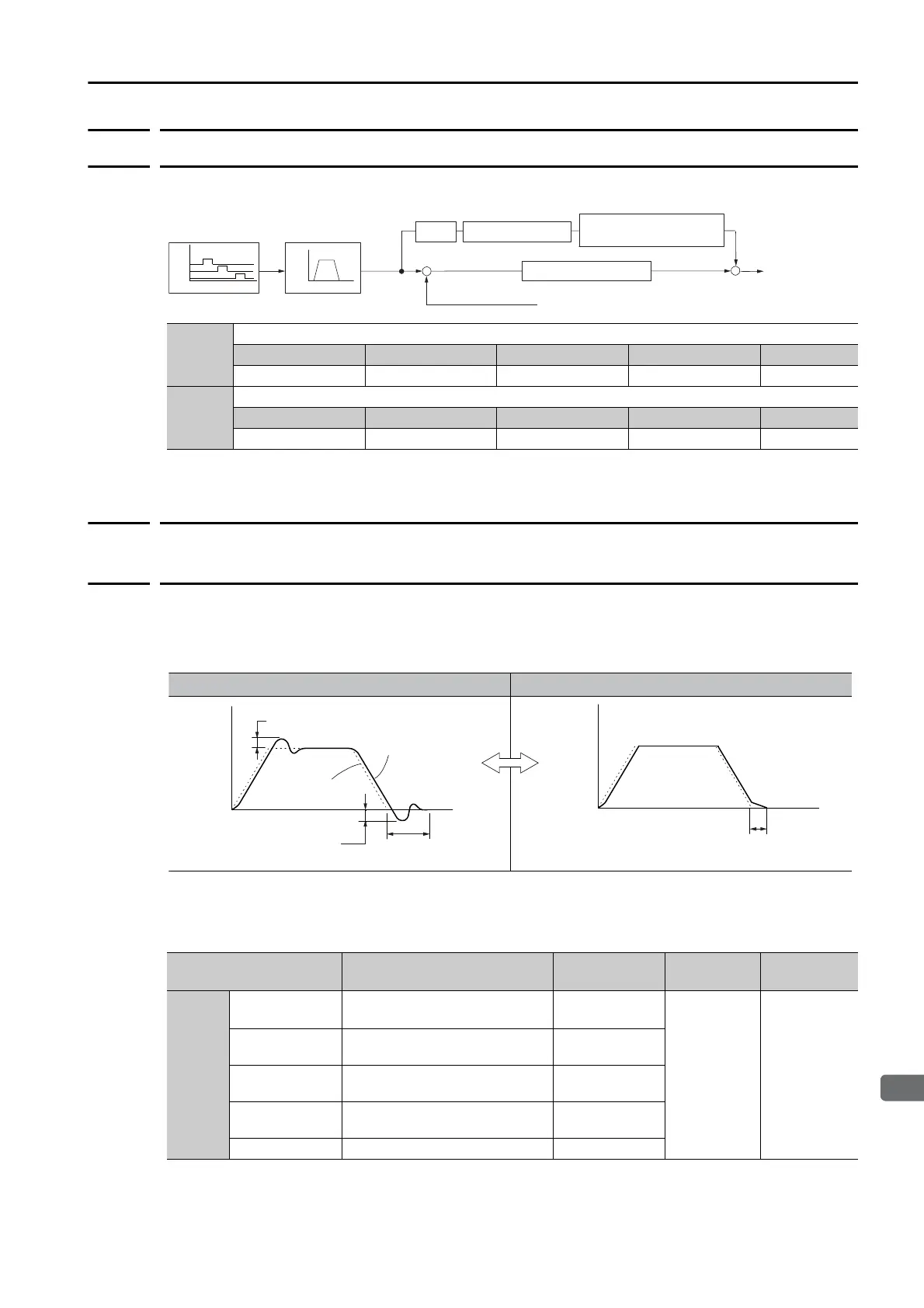

The feedforward function applies feedforward compensation to shorten the positioning time.

Note: If you set the feedforward value too high, the machine may vibrate. As a guideline, use a setting of 80% or

less.

8.8.3

Mode Switching (Changing between Proportional and PI

Control)

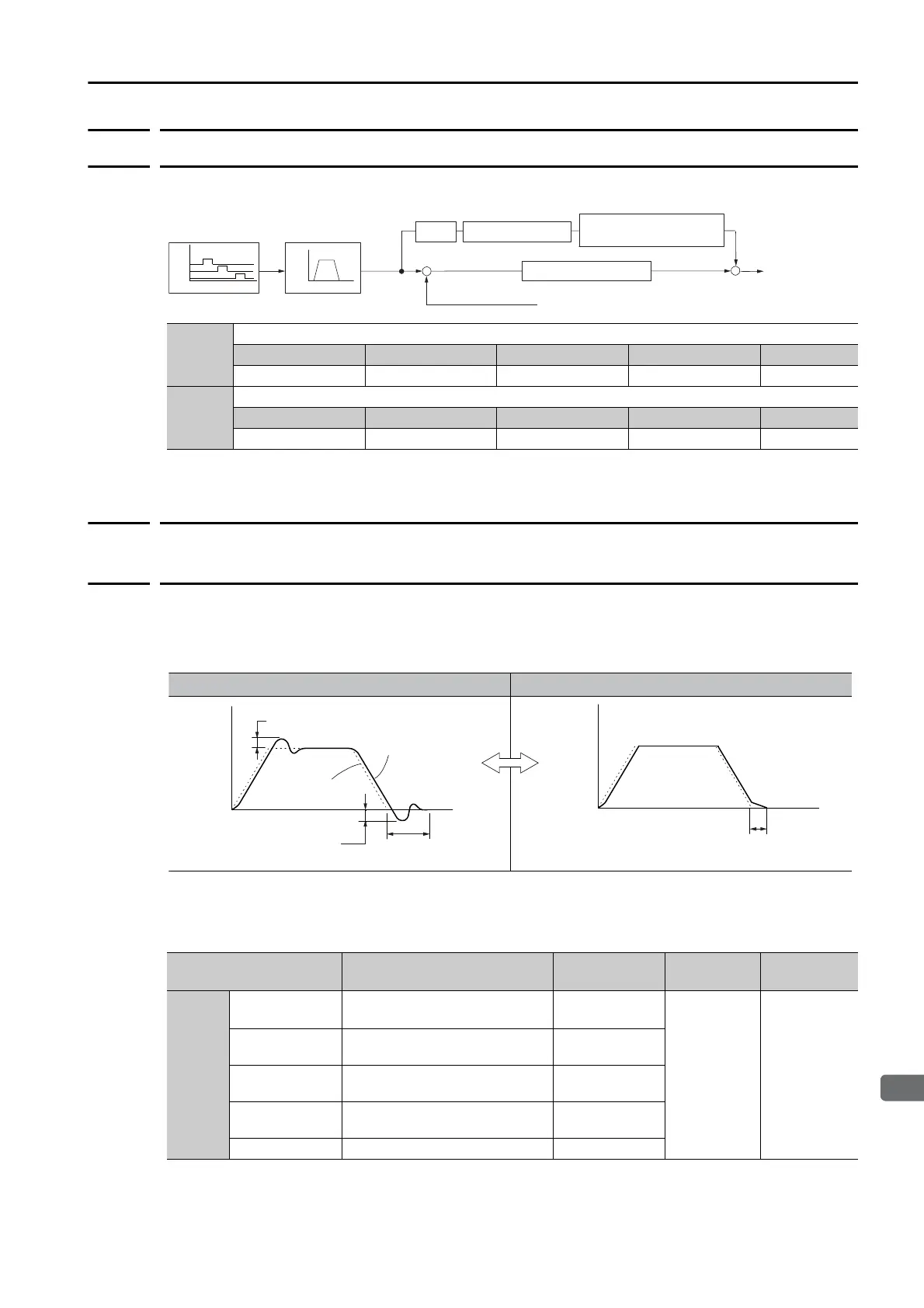

You can use mode switching to automatically change between proportional control and PI con-

trol.

Overshooting caused by acceleration and deceleration can be suppressed and the settling time

can be reduced by setting the switching condition and switching levels.

Related Parameters

Select the switching condition for mode switching with Pn10B = n.X.

Pn109

Feedforward

Setting Range Setting Unit Default Setting When Enabled Classification

0 to 100 1% 0 Immediately Tuning

Pn10A

Feedforward Filter Time Constant

Setting Range Setting Unit Default Setting When Enabled Classification

0 to 6,400 0.01 ms 0 Immediately Tuning

Feedback pulses

+

+

+

-

Position loop gain (Kp)

Pn109

Pn10A

Differential

Feedforward

Feedforward Filter

Time Constant

Speed

Speed pattern

Time

Movement

reference

Program table

Input

Signals

Time

Input pattern

Input

Parameter Mode Switching Selection

Parameter That

Sets the Level

When

Enabled

Classification

Pn10B

n.0

[default setting]

Use the internal torque refer-

ence as the condition.

Pn10C

Immediately Setup

n.1

Use the speed reference as the

condition.

Pn10D

n.

2

Use the acceleration reference

as the condition.

Pn10E

n.

3

Use the position deviation as

the condition.

Pn10F

n.

4 Do not use mode switching. -

Without Mode Switching With Mode Switching

Motor

speed

Overshooting

Actual Servomotor

operation

Reference

Time

Settling time

Overshooting

Motor

speed

Settling time

Time

Loading...

Loading...