8.8 Manual Tuning

8.8.1 Tuning the Servo Gains

8-32

8.8

Manual Tuning

This section describes manual tuning.

8.8.1

Tuning the Servo Gains

Servo Gains

In order to manually tune the servo gains, you must understand the configuration and charac-

teristic of the SERVOPACK and adjust the servo gains individually. In most cases, if you greatly

change any one parameter, you must adjust the other parameters again. Monitor the response

characteristic with the trace function of the SigmaWin+ while you make the adjustment.

The SERVOPACK has three feedback systems (the position loop, speed loop, and current

loop), and the response characteristic must be increased more with the inner loops. If this rela-

tionship is not maintained, the response characteristic will suffer and vibration will occur more

easily.

A sufficient response characteristic is ensured for the current loop. There is never a need for it

to be adjusted by the user.

Outline

You can use manual tuning to set the servo gains in the SERVOPACK to increase the response

characteristic of the SERVOPACK.

Use manual tuning in the following cases.

• When custom tuning does not work well

• When you want to increase the servo gains higher than the results of custom tuning

• When you want to determine the servo gains and moment of inertia ratio yourself

The operation is started with the default settings for the servo gain parameters.

Applicable Tools

You can monitor the servo gains with the SigmaWin+.

Precautions

Vibration may occur while you are tuning the servo gains. You must provide an emergency stop

device and activate it immediately whenever vibration occurs.

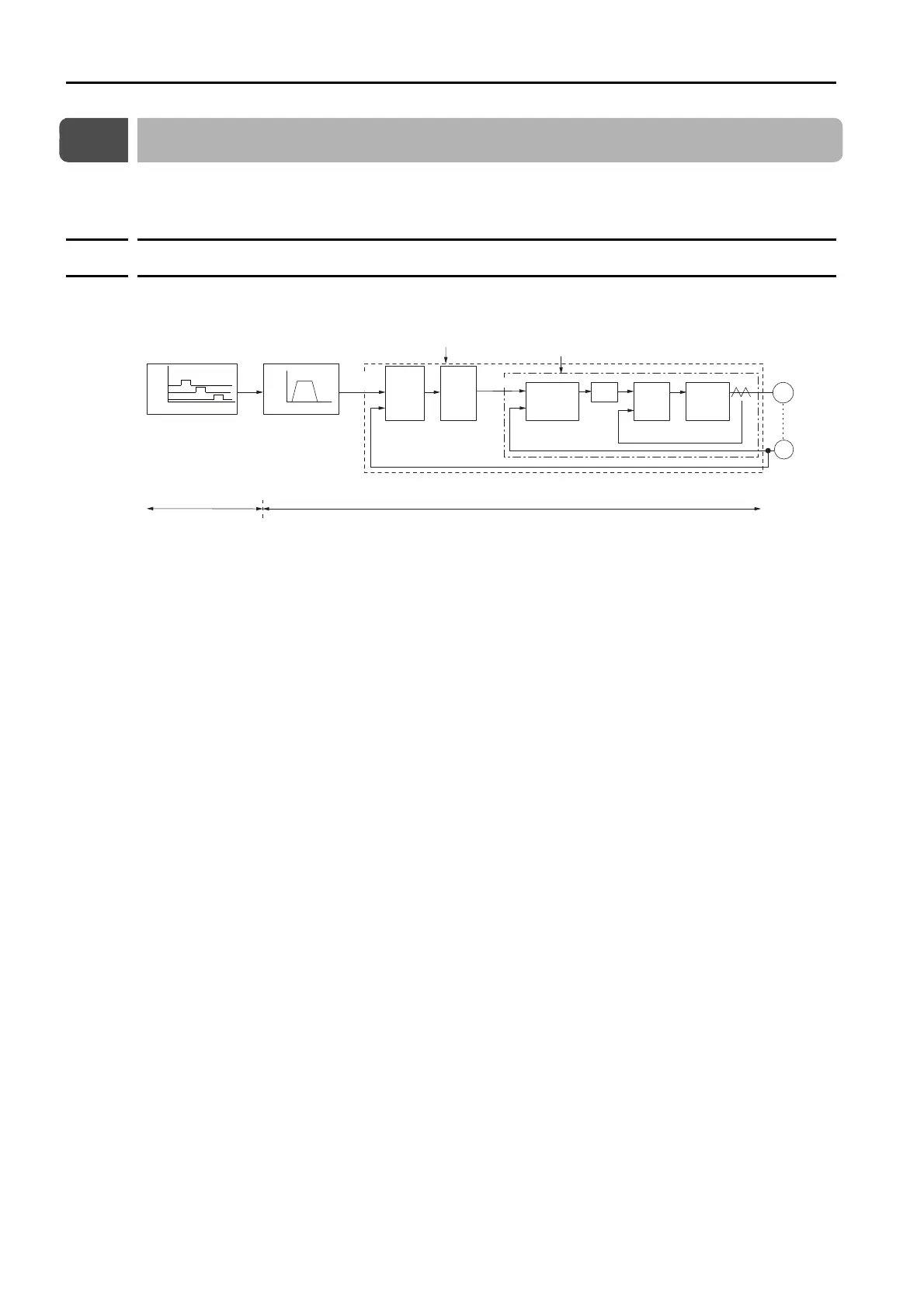

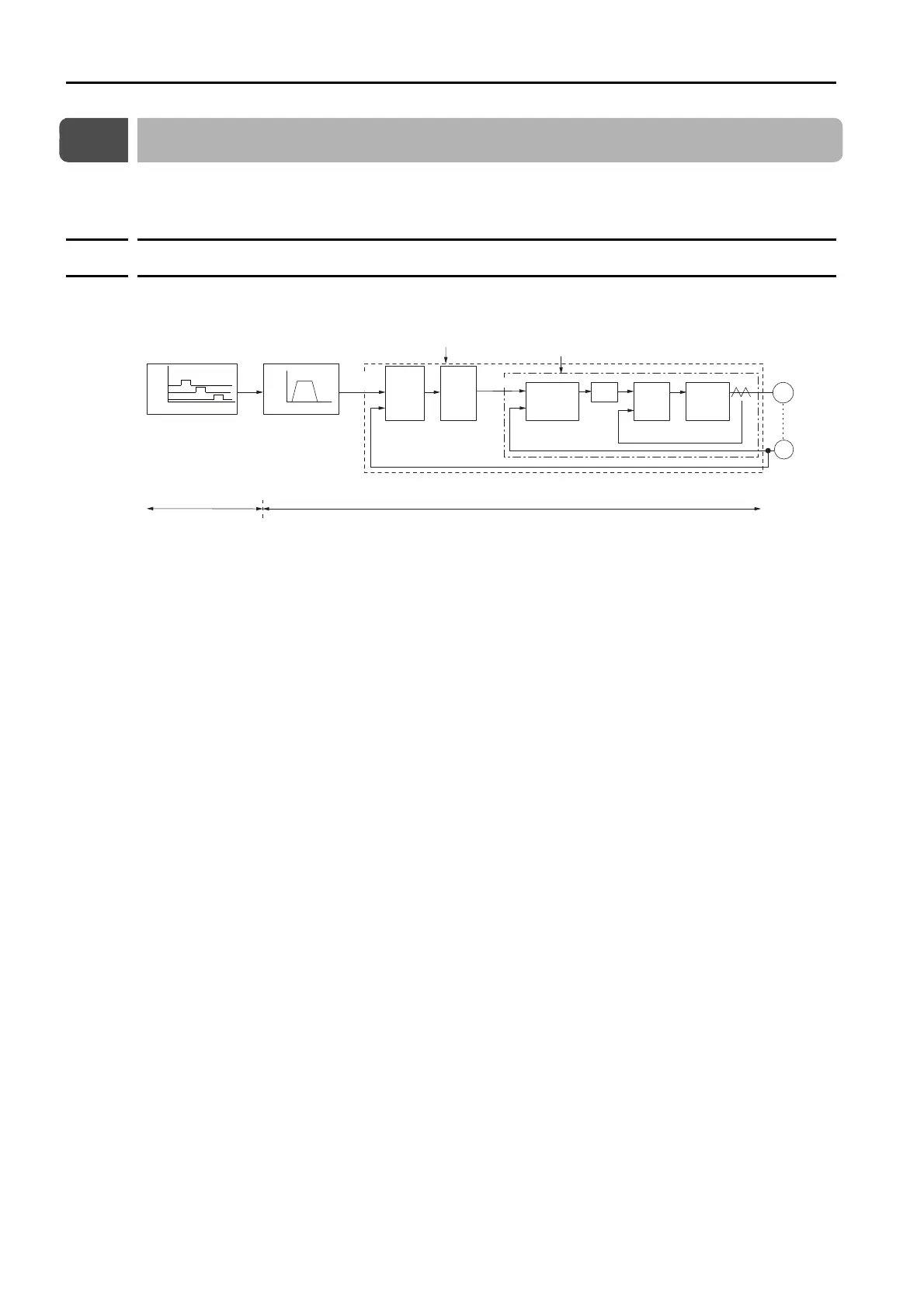

Encoder

Position control loop

Speed control loop

Speed

Speed pattern

Time

Deviation

counter

Position

loop

gain

Kp

Speed control

section

Kv and Ti

+

-

Current

control

section

Power

converter

Servomotor

M

PG

Position loop

SERVOPACK

Program table

Host controller

(Not provided by Yaskawa)

Kp: Position loop gain (Pn102)

Kv: Speed loop gain (Pn100)

Ti: Speed loop integral time constant (Pn101)

Tf: First stage rst torque reference lter time constant (Pn401)

Input

Signals

+

-

+

-

Speed loop

Current loop

Tf

Time

Input pattern

Input

Movement

reference

Speed

reference

Loading...

Loading...