2.4 Selecting the Servomotor Capacity

2.4.1 Example of Capacity Selection for Servomotors

2-12

2.4

Selecting the Servomotor Capacity

When you select a Servomotor capacity, refer to the following selection example procedure.

2.4.1

Example of Capacity Selection for Servomotors

1.

Machine Specifications

2.

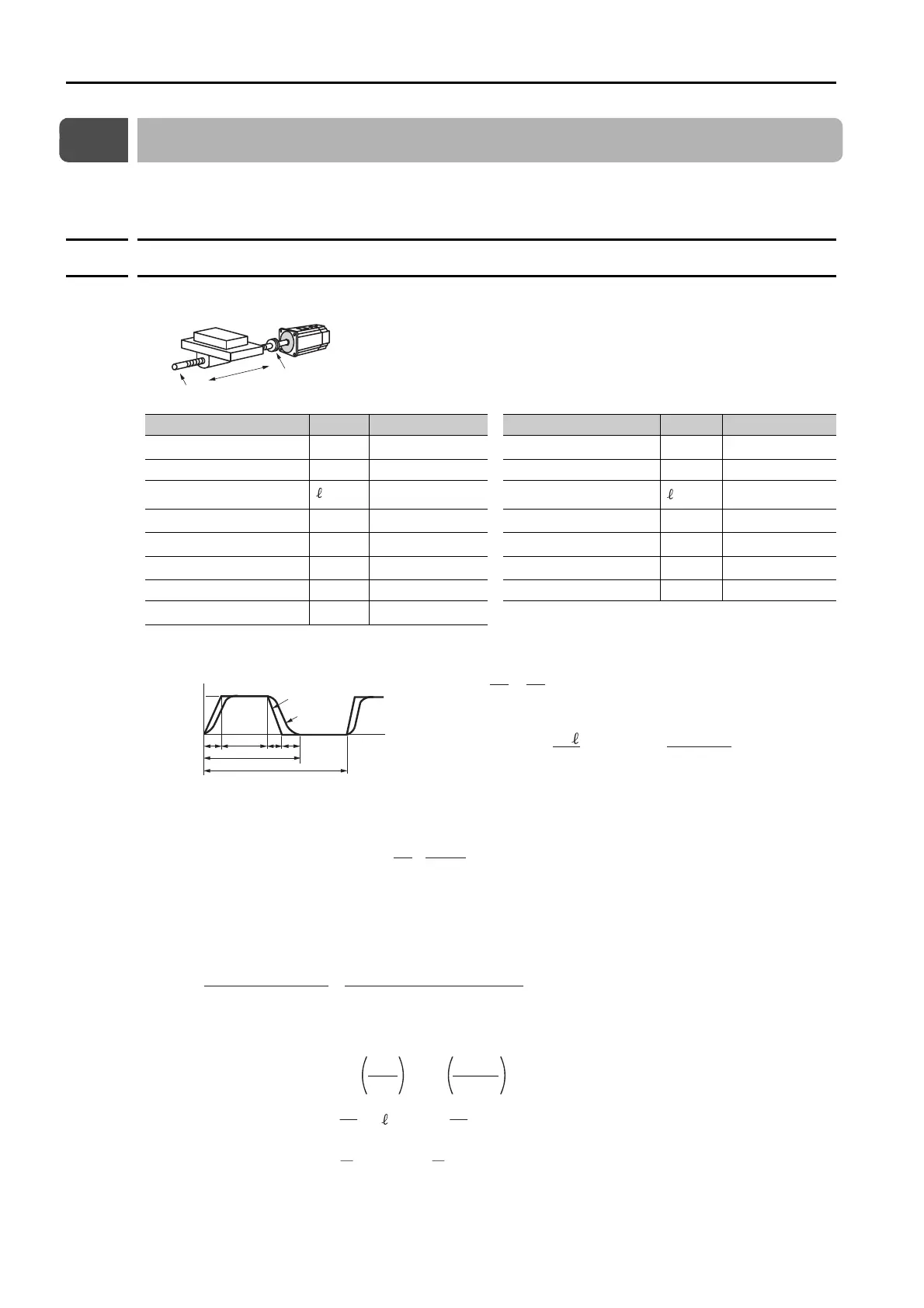

Speed Diagram

3.

Motor speed

4.

Load Torque

5.

Load Moment of Inertia

Item Symbol Value Item Symbol Value

Load Speed

υ

L

15 m/min

Coupling Outer Diameter

d

C

0.03 m

Linear Motion Section Mass

m 20 kg

Number of Feeding Operations

n 40 rotations/min

Ball Screw Length

B

0.3 m Feeding Distance 0.25 m

Ball Screw Diameter

d

B

0.008 m Feeding Time tm 1.2 s max.

Ball Screw Lead

P

B

0.005 m

Electrical Stopping Precision

δ

±0.02 mm

Ball Screw Material Density

ρ

7.87 × 10

3

kg/m

3

Friction Coefficient

μ

0.2

External Force on Linear Motion Section

F 0 N Mechanical Efficiency

η

0.9 (90%)

Coupling Mass

m

C

0.3 kg

• Load Shaft Speed

• Motor shaft speed Direct coupling gear ratio 1/R 1/R = 1/1

Therefore, n

M

= n

L

·R = 3,000 × 1 = 3,000 (min

-1

)

• Linear motion

section

• Ball screw

• Coupling

• Load moment of inertia at motor shaft

J

L

= J

L1

+ J

B

+ Jc = 0.474 × 10

-4

(kgm

2

)

Ball screw

Servomotor

Linear motion section

Coupling

υ

L

Load Speed

Reference Speed

Speed

(m/min)

Time (s)

tm

15

tcta td ts

t

υ

L

t = = = 1.5 (s)

if ta = td, ts = 0.1 (s),

ta = tm − ts − = 1.2 − 0.1 − = 0.1 (s)

tc = 1.2 − 0.1 − 0.1 × 2 = 0.9 (s)

60

n

60

40

60 × 0.25

15

60

υ

L

L

= = = 3000 (min

-1

)

P

B

15

0.005

υ

L

T

L

= = = 0.035 (N

m)

2πR ·

(9.8 · m + F ) · P

B

2π×1 × 0.9

(9.8 × 0.2 × 20 + 0) × 0.005

μ

η

J

L1

= m = 20 × = 0.127 × 10

-4

(kg

m

2

)

2

2πR

P

B

2

2π×1

0.005

B

= ·

B

· d

B

4

= × 7.87 × 10

3

× 0.3 × (0.008)

4

= 0.009 × 10

-4

(kg

m

2

)

32

π

32

π

ρ

c = m

C ·

d

C

2

= × 0.3 × (0.03)

2

= 0.338 × 10

-4

(kg

m

2

)

8

1

8

1

Loading...

Loading...