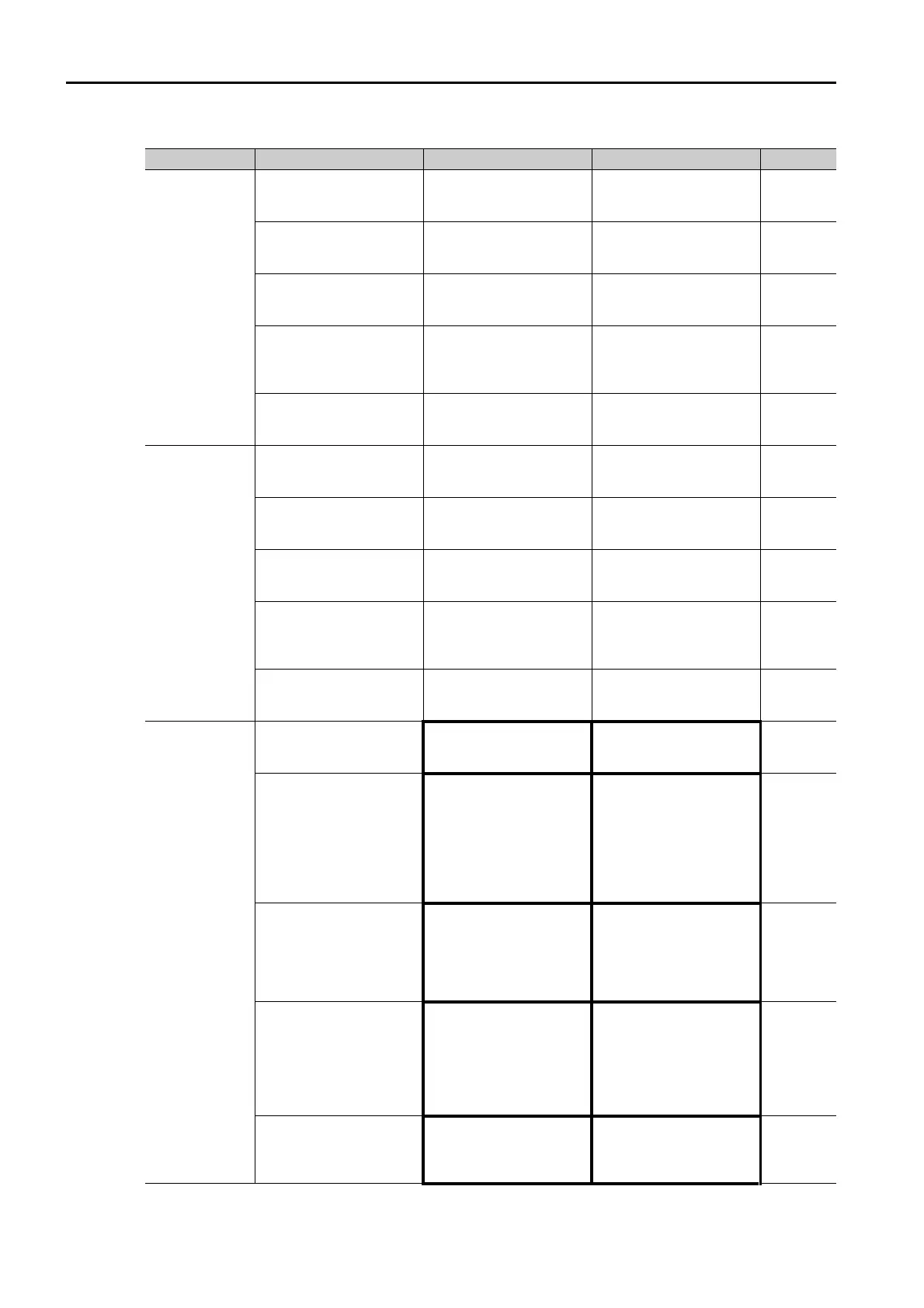

10.2 Troubleshooting Based on the Operation and Conditions of the Servo Drive

10-22

Motor Vibration

The servo gains are not

balanced.

Check to see if the servo

gains have been cor-

rectly tuned.

Execute custom tuning.

page 8-15

The setting of Pn100

(Speed Loop Gain) is too

high.

Check the setting of

Pn100. The default set-

ting is Kv = 40.0 Hz.

Set Pn100 to an appro-

priate value.

−

The setting of Pn102

(Position Loop Gain) is

too high.

Check the setting of

Pn102. The default set-

ting is Kp = 40.0/s.

Set Pn102 to an appro-

priate value.

−

The setting of Pn101

(Speed Loop Integral

Time Constant) is not

appropriate.

Check the setting of

Pn101. The default set-

ting is Ti = 20.0 ms.

Set Pn101 to an appro-

priate value.

−

The setting of Pn103

(Moment of Inertia Ratio)

is not appropriate.

Check Pn103 (Moment

of Inertia Ratio).

Set Pn103 (Moment of

Inertia Ratio) to an

appropriate value.

−

Large Motor

Speed

Overshoot on

Starting and

Stopping

The servo gains are not

balanced.

Check to see if the servo

gains have been cor-

rectly tuned.

Execute custom tuning.

page 8-15

The setting of Pn100

(Speed Loop Gain) is too

high.

Check the setting of

Pn100. The default set-

ting is Kv = 40.0 Hz.

Set Pn100 to an appro-

priate value.

−

The setting of Pn102

(Position Loop Gain) is

too high.

Check the setting of

Pn102. The default set-

ting is Kp = 40.0/s.

Set Pn102 to an appro-

priate value.

−

The setting of Pn101

(Speed Loop Integral

Time Constant) is not

appropriate.

Check the setting of

Pn101. The default set-

ting is Ti = 20.0 ms.

Set Pn101 to an appro-

priate value.

−

The setting of Pn103

(Moment of Inertia Ratio)

is not appropriate.

Check Pn103 (Moment

of Inertia Ratio).

Set Pn103 (Moment of

Inertia Ratio) to an

appropriate value.

−

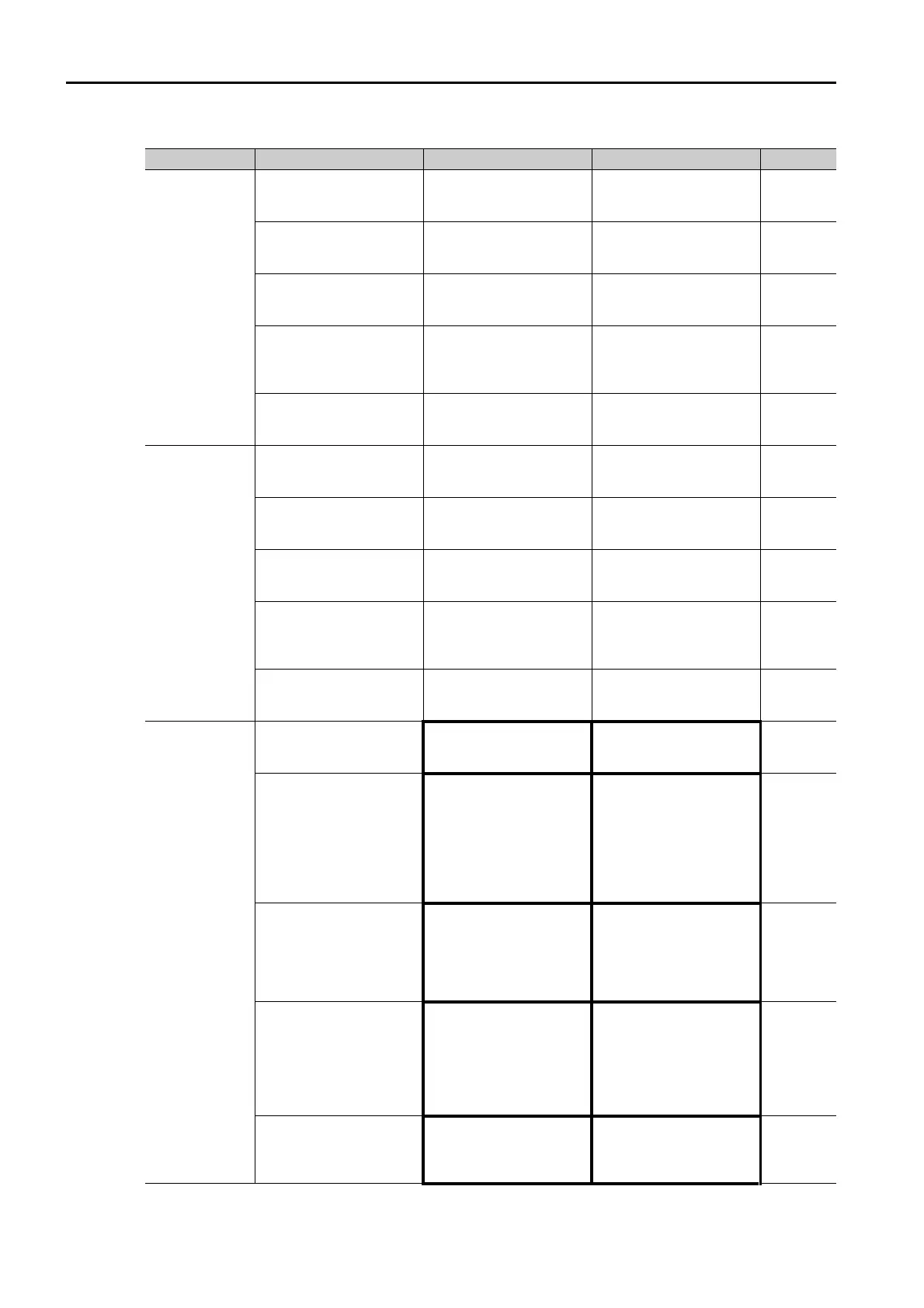

Position

Deviation

(without Alarm)

The Encoder Cable does

not satisfy specifications.

Check the Encoder

Cable to see if it satisfies

specifications.

Use cables that satisfy

the specifications.

−

There is excessive exter-

nal noise interference on

the Encoder Cable.

Check to see if the

Encoder Cable is bun-

dled with a high-current

line or installed near a

high-current line. Check

to see if there is noise

interference on the signal

line from the encoder.

Correct the cable layout

so that no surge is

applied by high-current

lines. Take measures to

prevent noise interfer-

ence from the signal lines

on the encoder cable.

−

There is variation in the

FG potential because of

the influence of

machines on the Servo-

motor side, such as a

welder.

Check to see if the

machines are correctly

grounded.

Properly ground the

machines to separate

them from the FG of the

encoder.

−

The encoder was sub-

jected to excessive

vibration or shock.

Check to see if vibration

from the machine

occurred. Check the Ser-

vomotor installation

(mounting surface preci-

sion, securing state, and

alignment).

Reduce machine vibra-

tion. Or, improve the

mounting conditions of

the Servomotor.

−

The coupling between

the machine and Servo-

motor is not suitable.

Check to see if position

offset occurs at the cou-

pling between machine

and Servomotor.

Correctly secure the cou-

pling between the

machine and Servomo-

tor.

−

Continued on next page.

Continued from previous page.

Problem Possible Cause Confirmation Correction Reference

Loading...

Loading...