4 Cabling the AC 800F

4-43

4.2.10.3 Long-distance links within buildings

The fiber optic 10BaseFL cables described in the examples above are two-wire,

ready-made cables with BFOC connectors. They are designed for dry indoor

applications. The maximum possible length of a ready-made cable is 100 m.

Longer fiber optic cables first have to be to laid without connectors to avoid the risk of

fiber breaks. In a second operation so-called pig-tails are welded (spliced) to the fiber

optic cables. Pig-tails are short fiber optic cables of around 10 m with a connector

plug mounted to one end. The splice points are protected by splice boxes, which are

available for wall mounting or ceiling suspension.

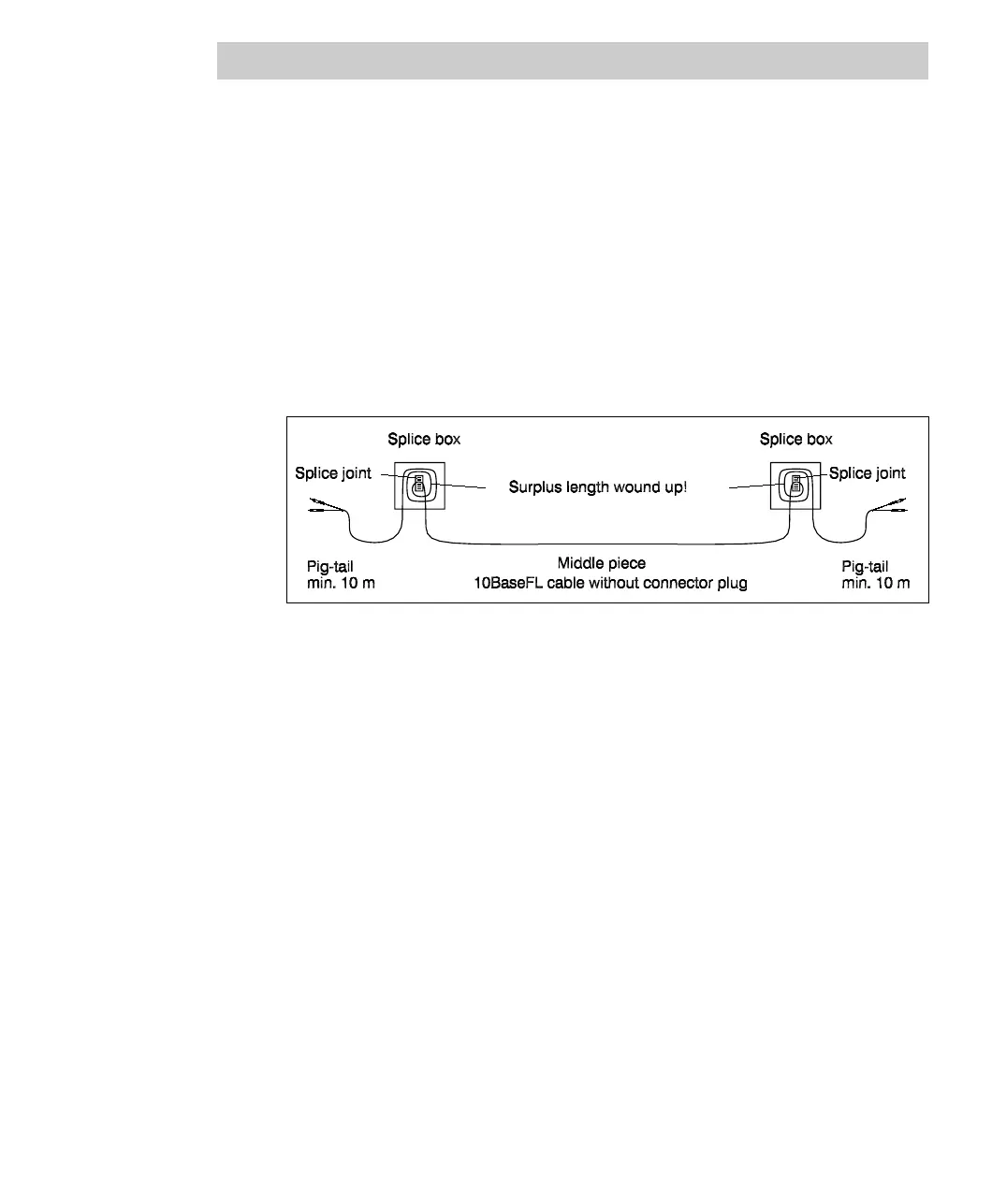

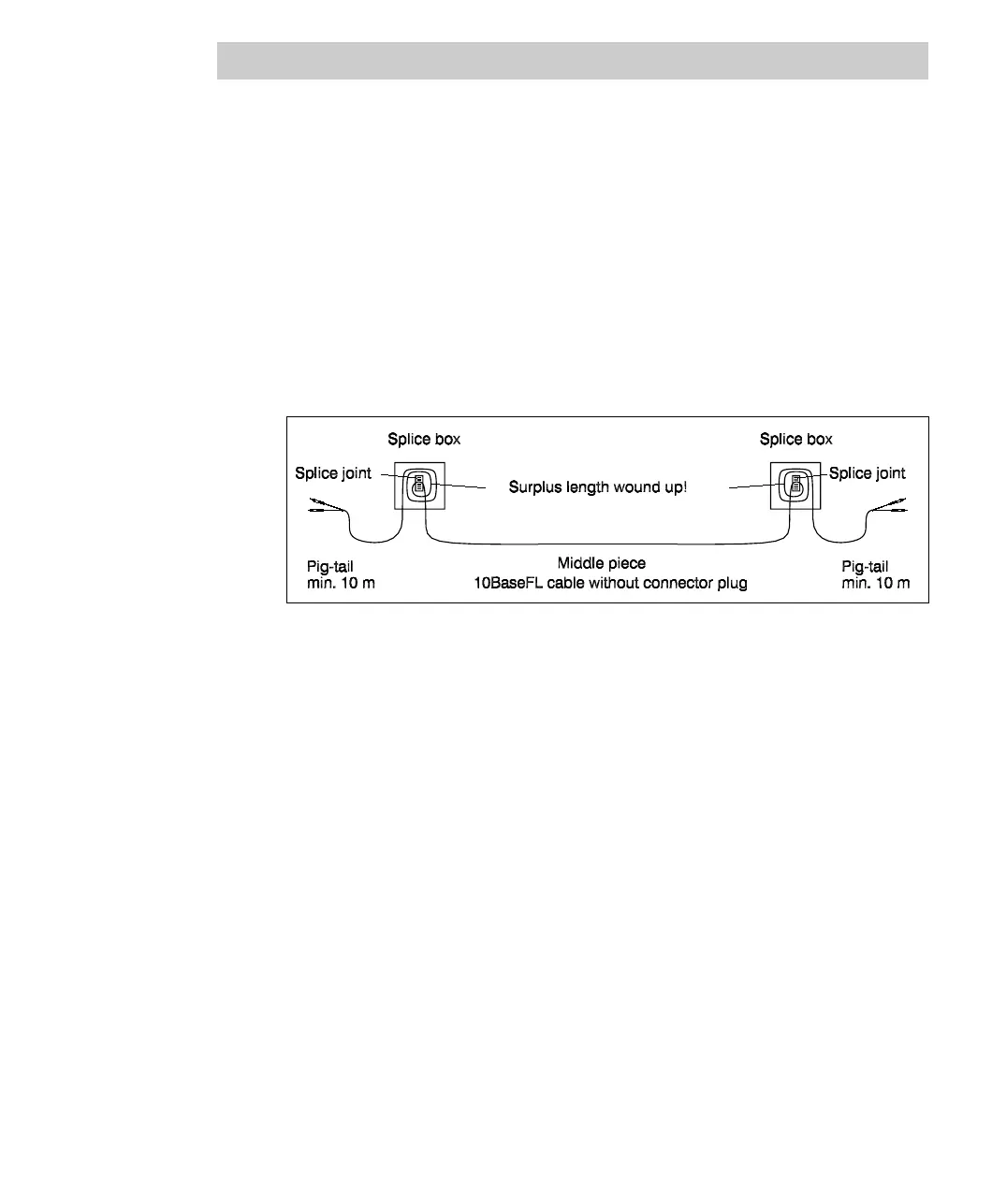

Figure 4-24 shows the basic structure of a point-to-point connection with two splice

boxes.

Fig. 4-24 Point-to-point connection with splice boxes

Note that the fiber optic cables are normally available in a maximum length of 2000 m.

For longer distances an additional splice box for connecting the middle pieces or an

overlength cable is required.

Splicing is a welding operation which must be carried out by qualified personnel, only.

Contact the ABB service for splicing works. Splicing pig-tails is easier than mounting

connectors to the middle piece on site. Therefore, splicing should be preferred. Make

sure that the splice points meet the quality requirements by measuring/testing the

whole link on site and noting down the results in an acceptance record.

Pig-tails can be produced by cutting a ready-made 10BaseFL cable in two pieces.

Pig-tails should have a maximum length of 6 ... 10 m to enable easy measurement.

The surplus length, if existing, can be wound up in the splice box.

Loading...

Loading...