Chapter 4 - Commissioning the System

94 AdeptModules Instruction Handbook, Volume 1: Adept MV Controller Interface, Rev. A

WARNING: Impact Hazard!

In Automatic mode no personnel are allowed in the workcell. The

AdeptModules can move at high speeds and exert considerable forces.

Calibration involves limited AdeptModules motion. Observe all safety

precautions.

1. Set the VFP operating keyswitch to the AUTO position and verify that the other

keyswitch is in the LOCAL position. If necessary, reenable High Power.

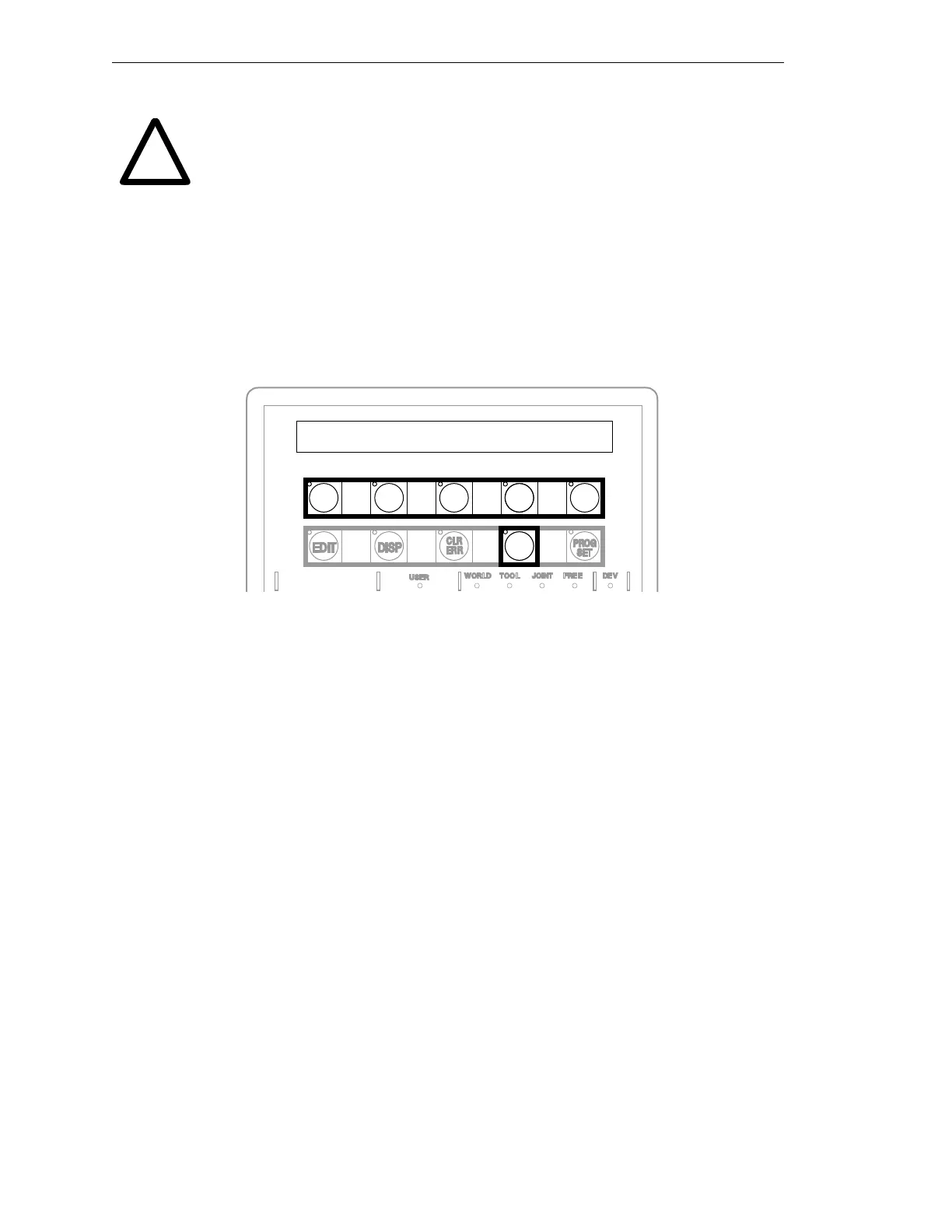

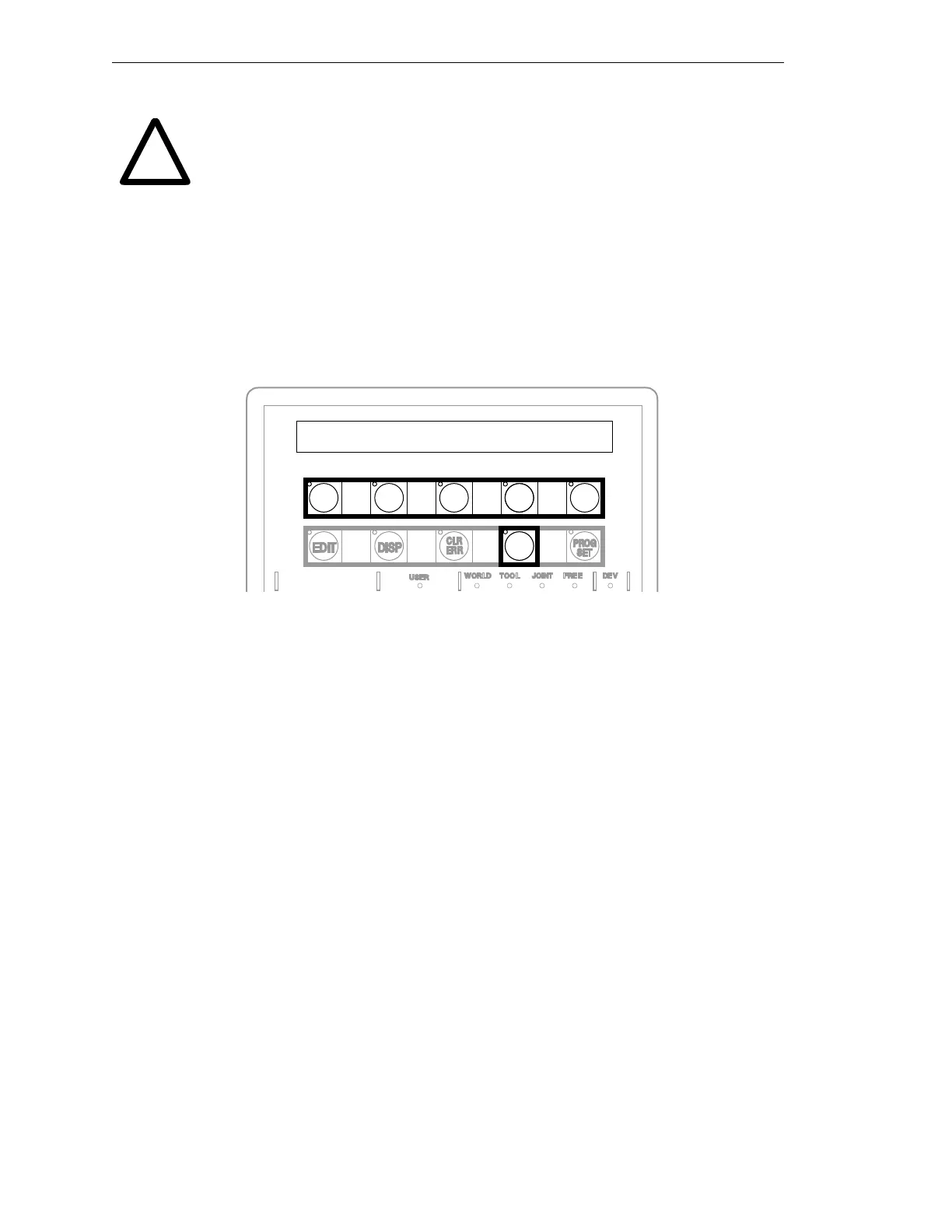

2. Press the CMD soft button to display the MCP functions (see Figure 4-3).

3. Ensure that none of the joints are positioned at the end of their travel, covering the

sensors. This will cause calibration errors. Position the joints in the middle of their

travel range.

Figure 4-3. Command (CMD) Function Button

4. Press the soft button below the text CALIB in the display to start calibration.

Changing Calibration Direction

AdeptModules calibrate by default toward the motor end of the module. By modifying

SPEC parameters and teaching calibration, the direction of travel for calibration can be

changed. The following steps should be used as a guideline for changing the parameters.

Adept assumes that the user has a working knowledge of SPEC and a general

understanding of kinematics before performing this procedure.

The direction of travel for calibration can be changed by changing the sign of the “Speed

and Direction of Search” parameter and then reteaching calibration.

1. Load and execute SPEC.V2 (see instructions on page 91 ).

2. Select “Edit Robot Specifications” from the main menu.

3. Select “Edit Motor Calibration Parameter” from the submenu.

4. Select and change the “Speed and Direction for Search” parameter sign.

5. Select “Teach calibration specs”.

SPEC will prompt in the following :

Before teaching calibration, you should:

1. Have properly tuned all motors.

!

CMD

AUTO

START

CALIB

STORE

ALL

CMD1

CMD2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...