202 Rockwell Automation Publication 6000-TD004D-EN-P - November 2017

Chapter 3 Fault Messages

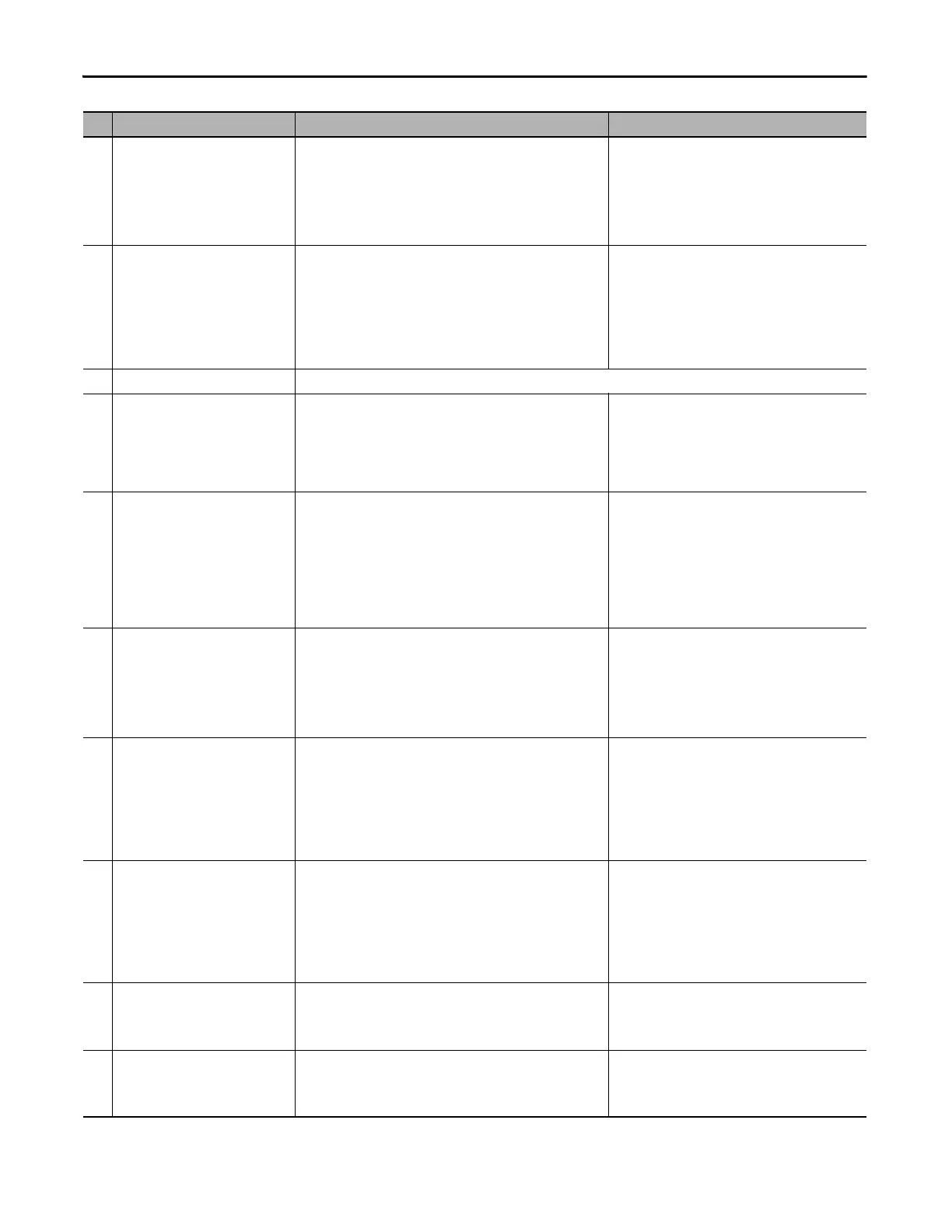

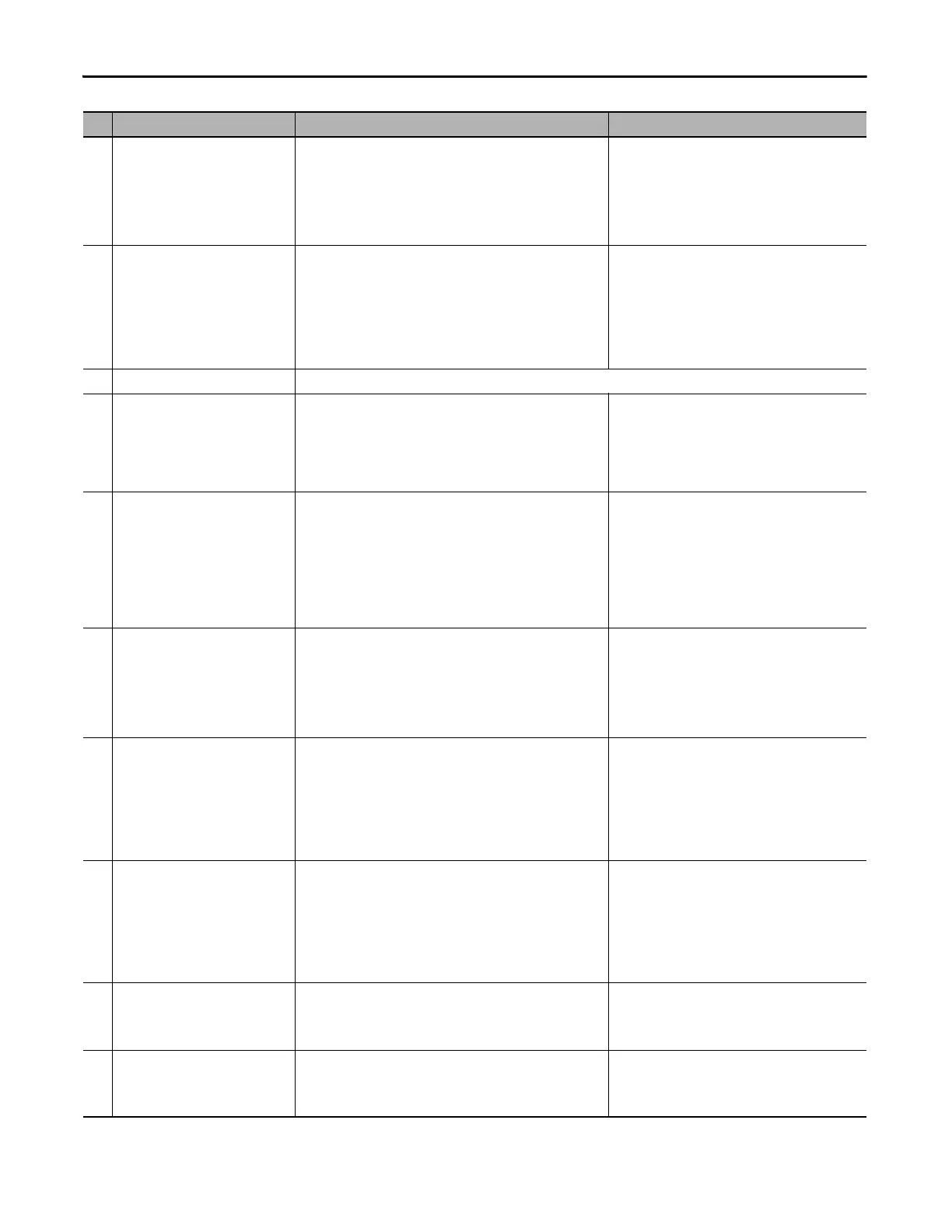

5 Abnormal Output Voltage The voltage on the motor side, measured through the VSB, is different

from the rated voltage at some frequency point.

If the difference has exceeded the Over Voltage Deviation Fault

Threshold (P224) for the duration set in Filter Time for Abnormal Output

Voltage (P211), this fault will be reported over 20% rated frequency.

• Check parameters Output Voltage Deviation Fault

Threshold (P224) and Filter Time For Output Over

Voltage (P221) are set correctly.

• Verify the VSB, resistor, and wire are not damaged.

• Check hardware on the AT board.

• Check PWM board is working normally.

• Check terminals on the control box.

6 Ground Fault The drive has detected a ground fault. The voltage between neutral

and ground is measured through the VSB.

This fault occurs if the voltage has exceeded the Ground Fault Trip

Threshold (P230) for the duration set in Filter Time for Ground Fault

(P228). When the voltage is less than the threshold set in Ground Fault

Warning Cancellation Threshold (P256), this fault disappears.

• Check parameters Ground Fault Trip Threshold (P230)

and Filter Time for Ground Fault (P228) are set

correctly.

• Verify the VSB, resistor, and wire are not damaged.

• Check hardware on the AT board.

• Verify output cable grounding.

• Verify motor stator winding grounding.

• Perform the ground insulation test.

7 Over Speed Fault This fault is reserved.

8 Motor Stalled The drive cannot detect the motor speed. The fault condition is

calculated using frequency.

This fault occurs when the absolute deviation between the system

output frequency and output absolute frequency has exceeded the

Motor Stalled Fault Threshold (P238) for the duration set in Motor Stall

Fault Delay (P239).

• Verify if load exceeds motor torque.

• Check parameters Motor Stalled Fault Threshold (P238)

and Motor Stall Fault Delay (P239) are set correctly.

9 Output Phase Over Current The output current on the motor side is measured through the current

sensor in the power cell cabinet.

This fault occurs when the phase current has exceeded Phase Over

Current Threshold (P210) for the duration set in Phase Over Current Filter

Time (P209) with the frequency lower than Phase Over Current Enable

Frequency Range Upper limit (P208).

• Check the motor side (excluding the motor) for issues.

• Check parameters Phase Over Current Threshold (P210)

and Phase Over Current Filter Time (P209) are set

correctly.

•

Check parameter Low Speed Voltage Compensation

(P451) is set based on the motor. If it was not, the

output current should be higher.

• Check drive for output phase loss.

• Check hardware on the AT board.

10 VFD Over Current 1 The drive has detected an over load fault. The VFD over current

condition is calculated using the A, C phase stator current, transfer the

stator current to VFD current, and the algorithm based on the over

current trip (Heating Current Threshold (P110) and VFDOverload Current

(P080)) and the delay set in VFD Overload Time (P081).

• Verify the sensor in the cabinet is working.

• Check parameters Heating Current Threshold (P110),

VFD Rated Current (P085), Motor Rated Current (P199),

and VFDOverload Current (P080) are set correctly.

• Check hardware on the AT board.

• Overloading, verify the load in the field.

• Check internal motor for failure.

11 Fan Failure in Fan Group #2 The drive has tripped because the fans in transformer cabinet 2 are in

abnormal status for the duration set in Fan Control TX Cabinet Fan Fault

Trip Delay (P116).

In non-redundant fan mode (Fan Control Mode (P094) = 0), there are

one or more fans with abnormal status. In redundant fan mode (Fan

Control Mode (P094) = 1 or 2), there are two or more fans with

abnormal status.

• Check parameter Fan Control Redundant Fan Working

Time (P101) and set a greater value.

• Check parameter Fan Control Group #2 Fan Number

(P096) and verify the number of fans.

• Check operation of fans in transformer cabinet 2.

• Check the status of the fan feedback relay and

command execution relay. Both status should be

identical.

12 Pre-charge Contactor Failure This fault occurs if the status of the pre-charge contactor is changed

within the duration set in Pre-charge Feedback Delay (P104).

• Check parameter Pre-charge Feedback Delay (P104) is

set correctly. There should be sufficient time for the

pre-charge contactor to execute the command and

the feedback signal to be sent to the control box.

• Check if the pre-charge contactor is available.

• Check the status of the pre-charge contactor indicator

light and the light on the DT board. Both status should

be identical.

13 Pre-charge Timeout The pre-charge duration has exceeded Pre-charge Max Time (P118). • Check parameter Pre-charge Max Time (P118) is set

correctly.

• Check pre-charge resistor and capacitor of power cell.

• Check line side voltage feedback.

14 Pre-charge Repeat Interval Low The pre-charge repeat interval is less than Pre-charge Min Repeat

Interval (P119).

• Check parameter Pre-charge Min Repeat Interval

(P119)

is set correctly.

• Check if operator performed the pre-charge interval

earlier than Pre-charge Min Repeat Interval (P119).

No. System Fault Message Description Recommended Action(s)

Loading...

Loading...