2-87

Confidential

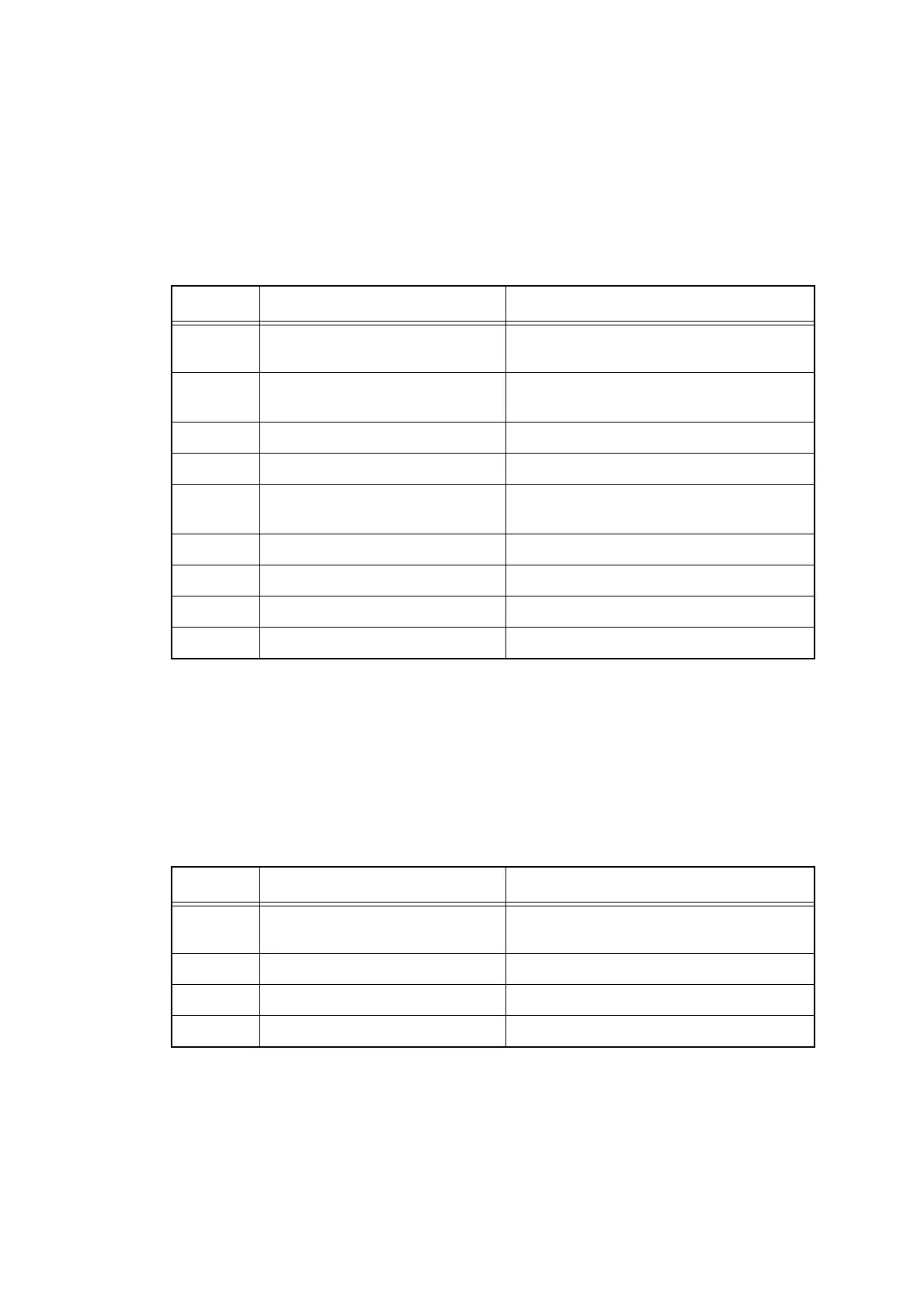

■ Paper jam at paper eject section

<User Check>

- Turn the orientation of the papers loaded in the paper tray by 180°.

- Check if the thickness of the paper is 60 to 105 g/m

2

.

(60 to 163 g/m

2

for manual feed slot.)

- Check if a label sticks to a roller or the paper transport section.

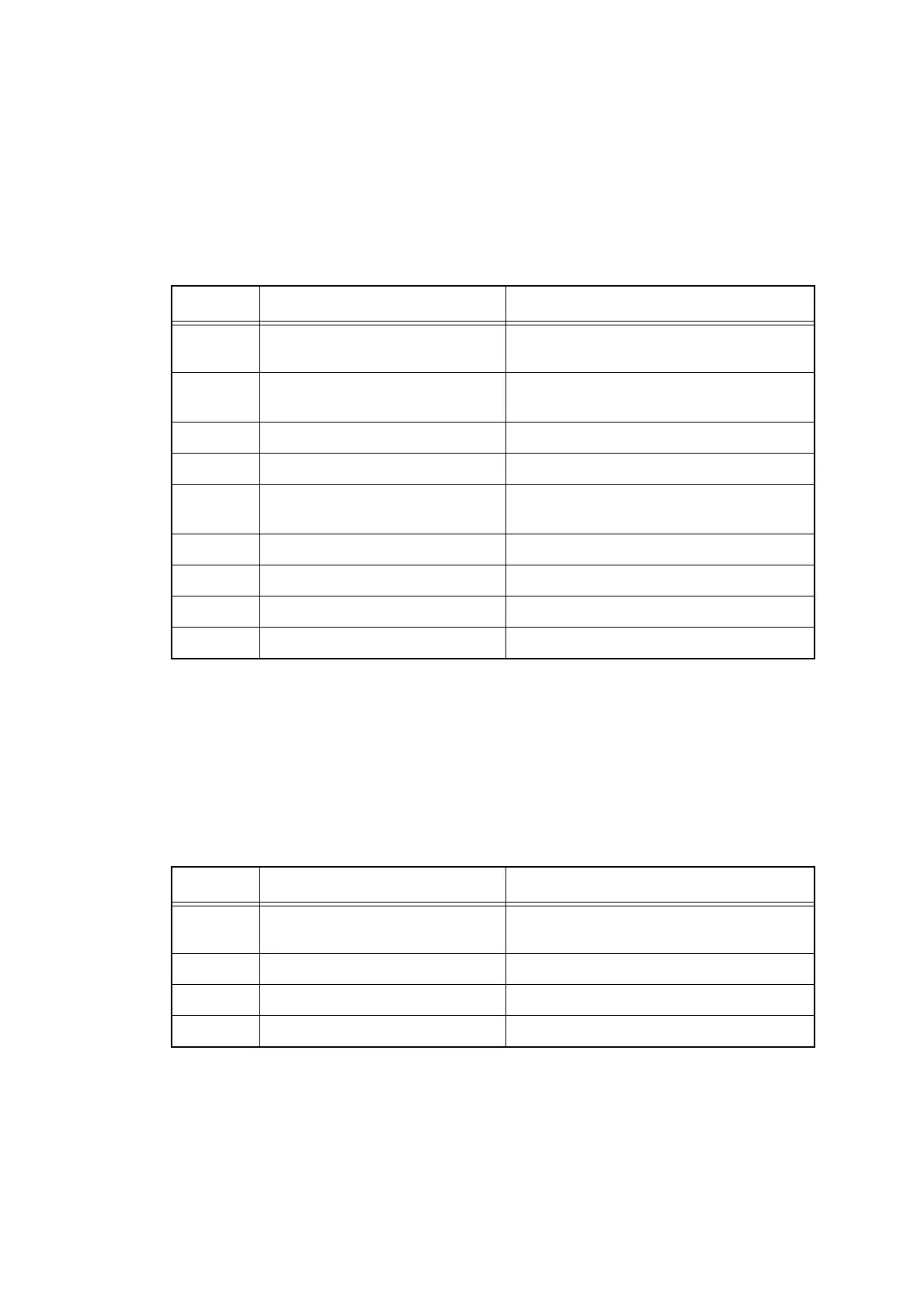

■ Paper jam at duplex tray section

<User Check>

- Turn the orientation of the papers loaded in the paper tray by 180°.

- Check if the thickness of the paper is 60 to 105 g/m

2

.

(60 to 163 g/m

2

for manual feed slot.)

- Check if a label sticks to a roller or the paper transport section.

Step Cause Remedy

1 Foreign object at the back of the

machine

Remove foreign object. Check if a label

sticks to the side or underside of a part.

2 Eject actuator catching on some

position

Re-assemble the eject actuator.

3 Fuser cover installation failure Re-assemble the fuser cover.

4 Back cover installation failure Re-assemble the back cover.

5 Eject sensor PCB harness

connection failure

Check the eject sensor PCB harness

connection and reconnect it.

6 Back cover failure Replace the back cover.

7 Eject roller 1 failure Replace the fuser cover.

8 Eject sensor failure Replace the eject sensor PCB ASSY.

9 Main PCB failure Replace the main PCB ASSY.

Step Cause Remedy

1 Foreign object inside the duplex

path

Remove foreign object. Check if a label

sticks to the side or underside of a part.

2 Fuser cover installation failure Re-assemble the fuser cover.

3 Back cover installation failure Re-assemble the back cover.

4 Main PCB failure Replace the main PCB ASSY.

Loading...

Loading...