2-34

Confidential

4. TROUBLESHOOTING

4.1 Error Cause and Remedy

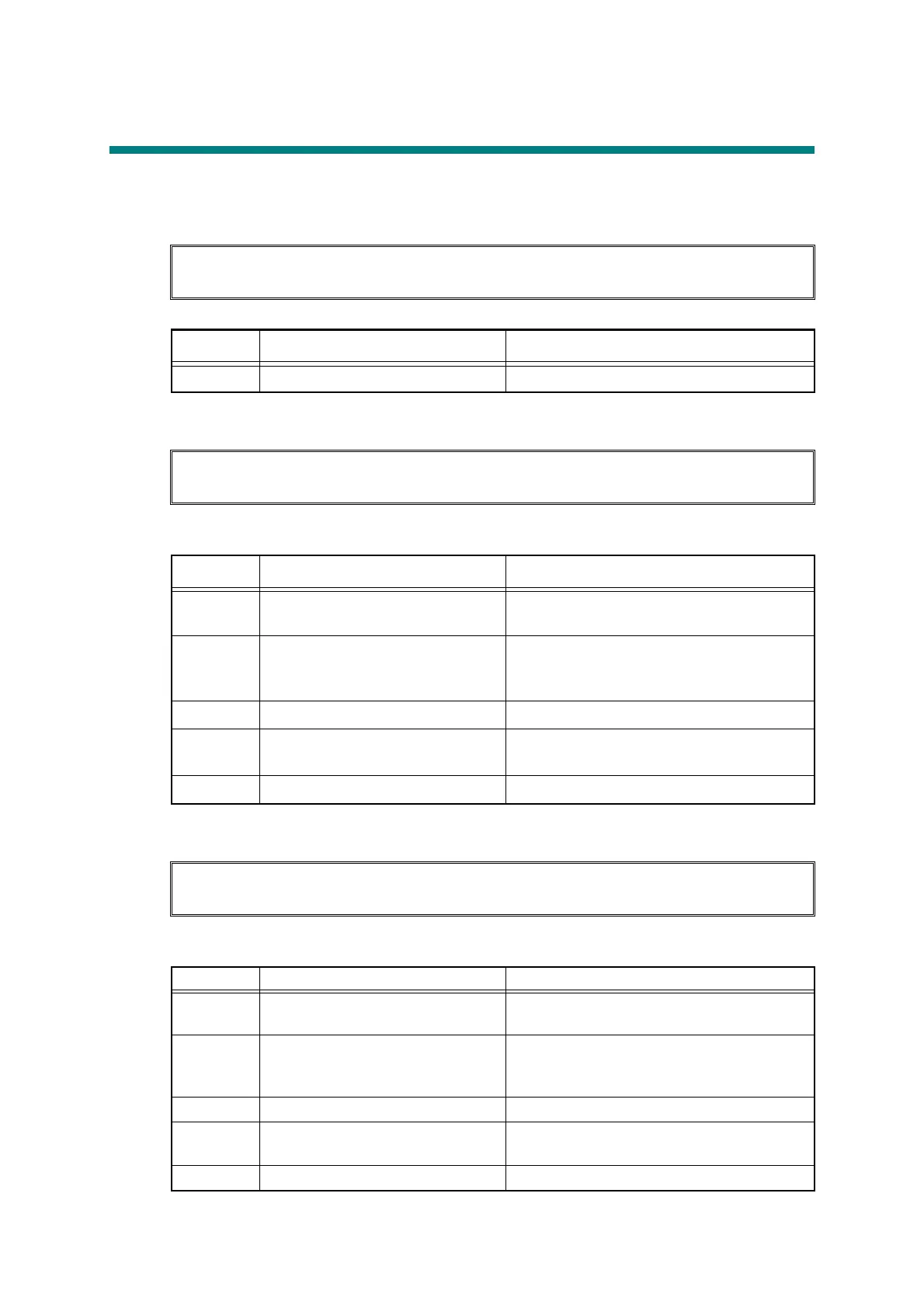

■ Error code 0100

ASIC error or motor driver error occurred.

■ Error code 0201

Synchronization signal from the main motor cannot be detected. Or the main motor speed is

unstable after a set period of time.

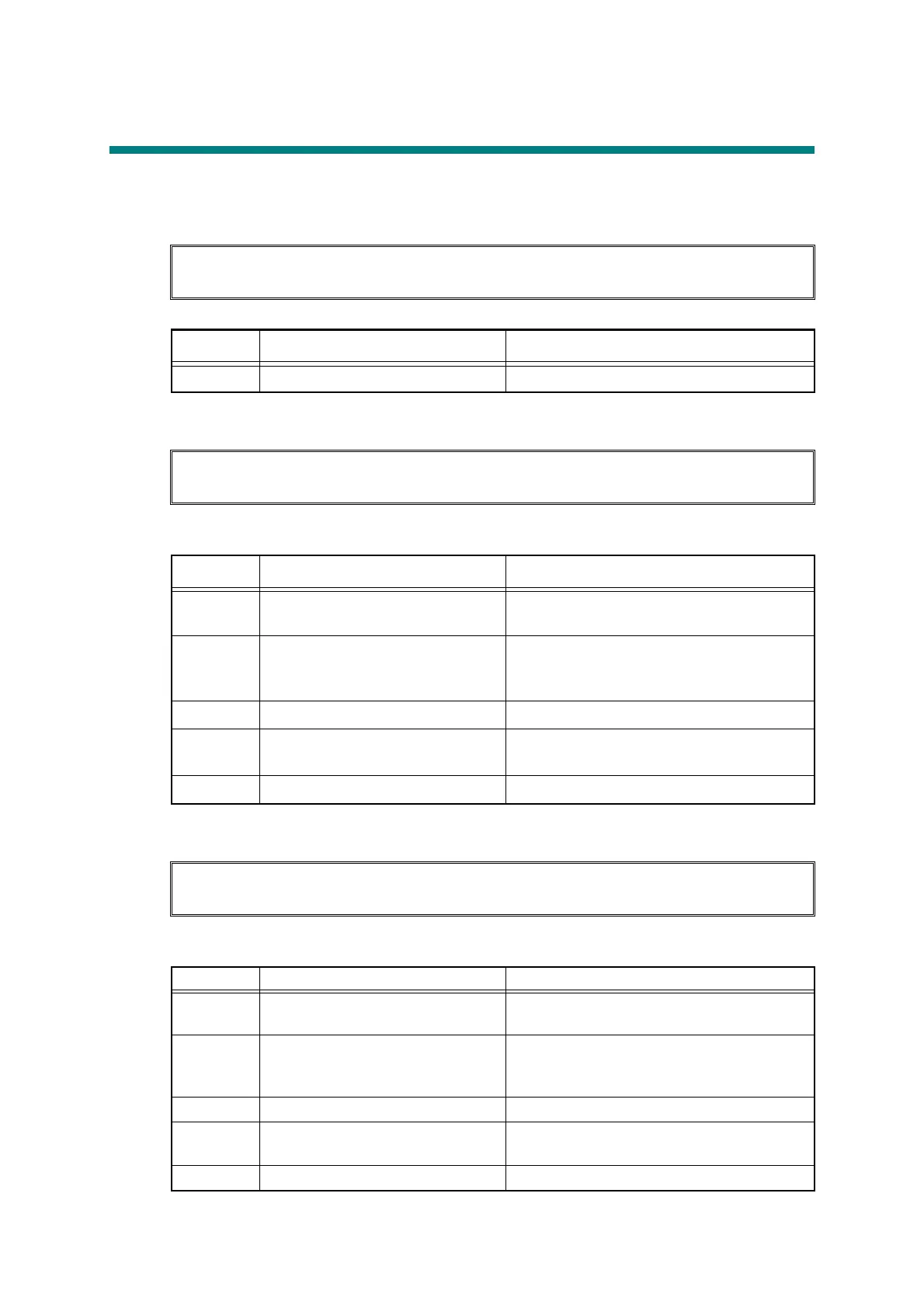

■ Error code 0202

Synchronization signal from the process motor cannot be detected. Or the process motor

speed is unstable after a set period of time.

Print Unable 01

Turn the power off and then back on again.

Step Cause Remedy

1 Main PCB failure Replace the main PCB ASSY.

Print Unable 02

Turn the power off and then back on again.

Step Cause Remedy

1 Main motor harness connection

failure

Check the main motor harness connection

and reconnect it.

2 Harness connection failure

between the low-voltage power

supply PCB and main PCB

Check the harness connection between

the low-voltage power supply PCB and

main PCB, and reconnect it.

3 Main motor failure Replace the process drive unit.

4 Low-voltage power supply PCB

failure

Replace the low-voltage power supply

PCB ASSY.

5 Main PCB failure Replace the main PCB ASSY.

Print Unable 02

Turn the power off and then back on again.

Step Cause Remedy

1 Process motor harness

connection failure

Check the process motor harness

connection and reconnect it.

2 Harness connection failure

between the low-voltage power

supply PCB and main PCB

Check the harness connection between

the low-voltage power supply PCB and

main PCB, and reconnect it.

3 Process motor failure Replace the process drive unit.

4 Low-voltage power supply PCB

failure

Replace the low-voltage power supply

PCB ASSY.

5 Main PCB failure Replace the main PCB ASSY.

Loading...

Loading...