2-109

Confidential

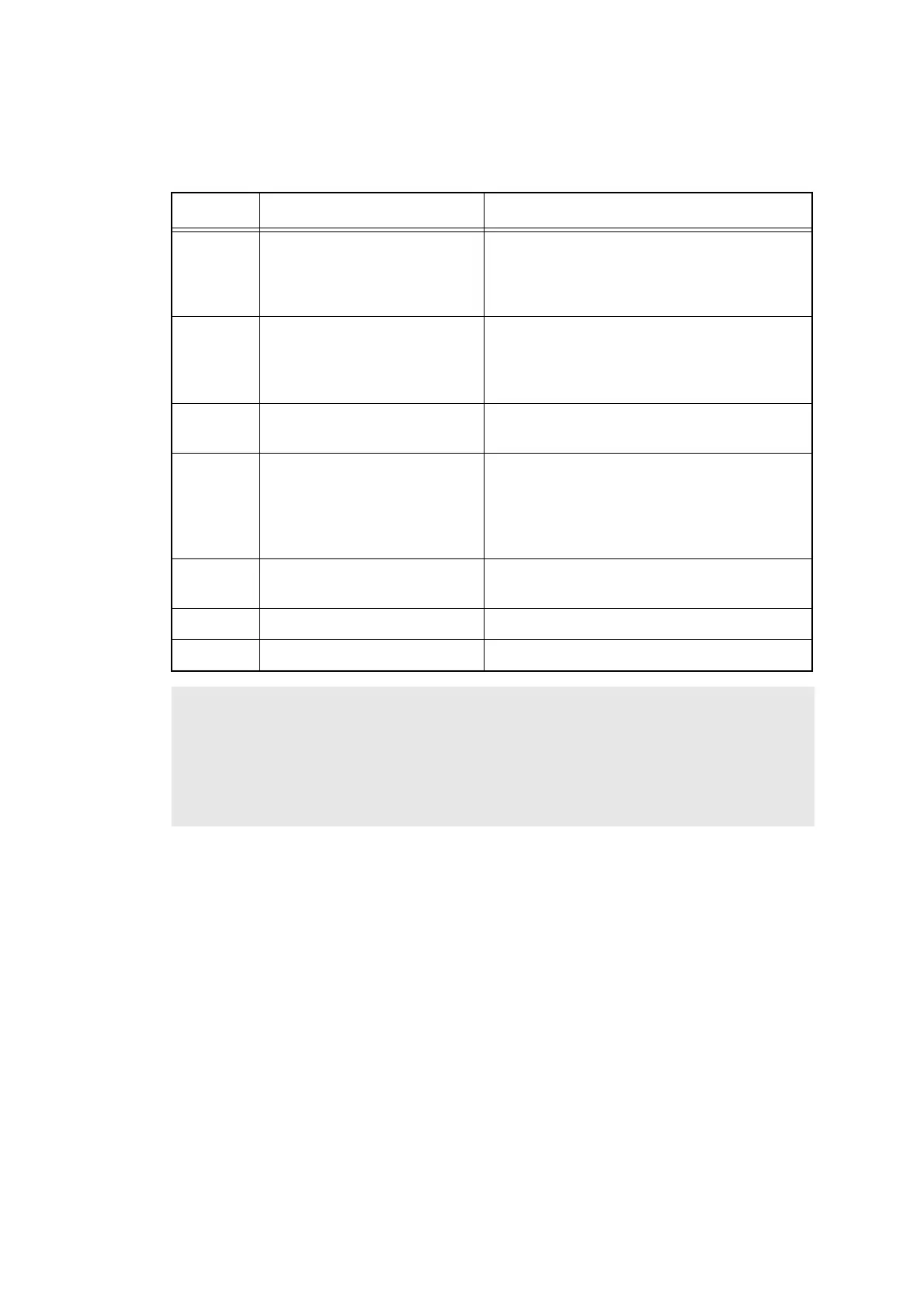

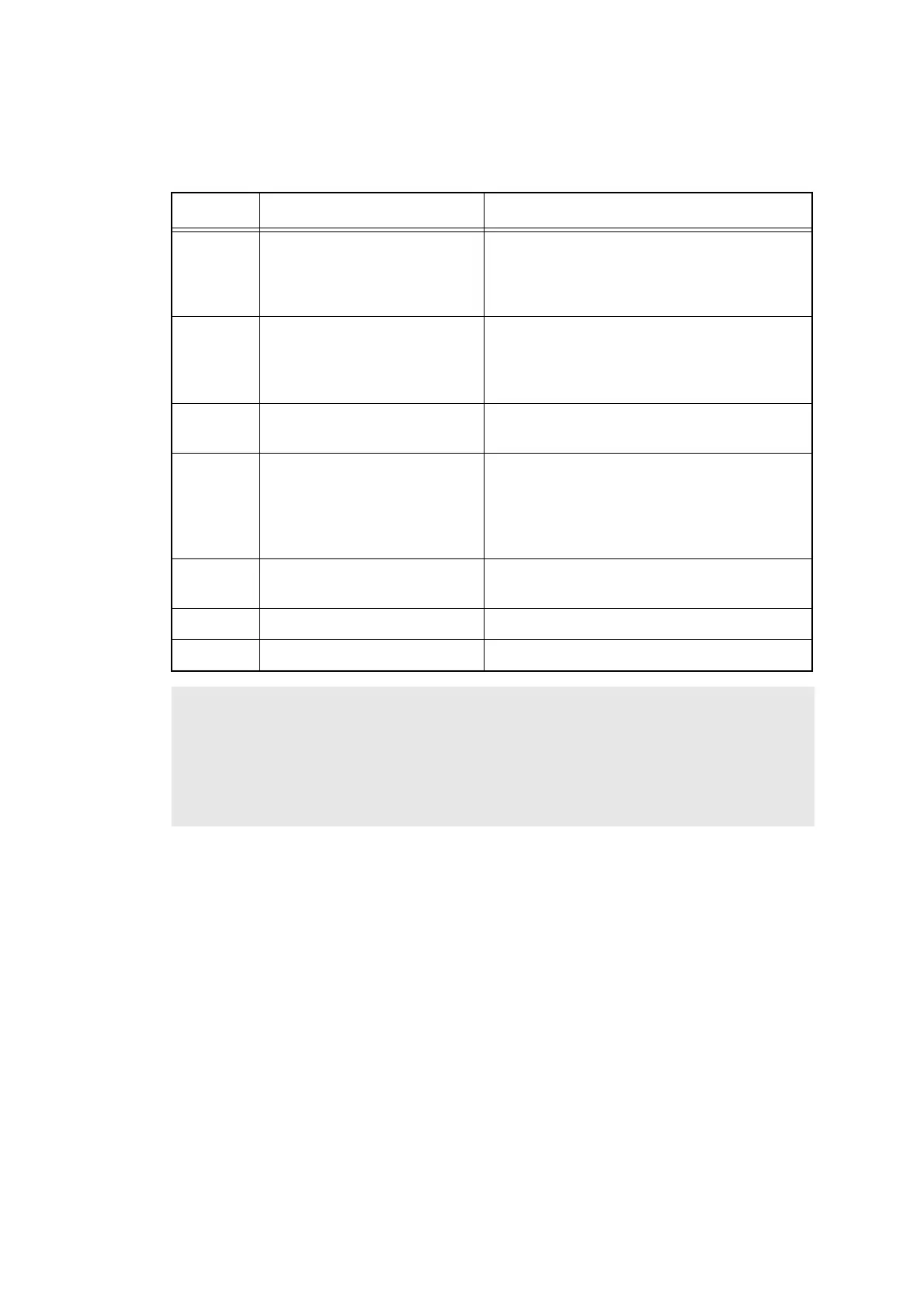

4.8 Troubleshooting of the Fuser Unit

4.8.1 Fuser unit failure

Step Cause Remedy

1 Harness connection failure

between the connector of the

fuser unit and eject sensor

PCB

Check the harness connection between the

connector of the fuser unit and eject sensor

PCB, and reconnect it.

2 Harness connection failure

between the connector of the

fuser unit and low-voltage

power supply PCB

Check the harness connection between the

connector of the fuser unit and low-voltage

power supply PCB, and reconnect it.

3 Harness connection failure of

the eject sensor PCB

Check the harness connection of the eject

sensor PCB and reconnect it.

4 Eject sensor PCB failure

Refer to "1.4.10 Operational check of sensors"

in Chapter 5 and check the operations of

sensors.

If sensor operation failure occurs, replace the

eject sensor PCB ASSY.

5 Low-voltage power supply

PCB failure

Replace the low-voltage power supply PCB

ASSY.

6 Fuser unit failure Replace the fuser unit.

7 Main PCB failure Replace the main PCB ASSY.

Note:

- Turn the power OFF and then ON again. After the machine is left as it is for about 10

minutes, this problem may be resolved.

- If test print is performed in maintenance mode for service personnel, the machine may

recover from the error. However, note that if this operation is performed while the heater

has not cooled down, the fuser unit may melt.

Loading...

Loading...