FUEL SYSTEM

CARBURETOR OPERATION

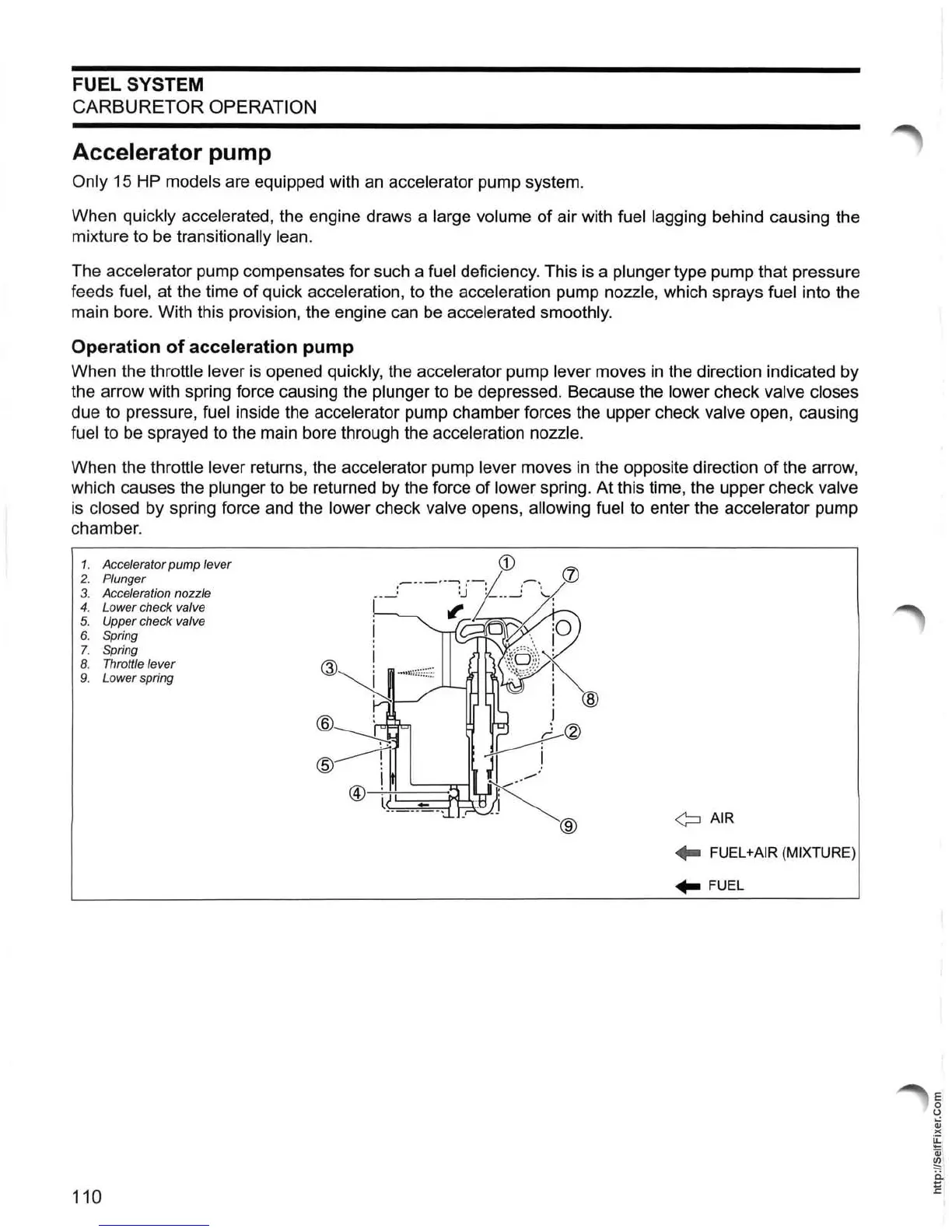

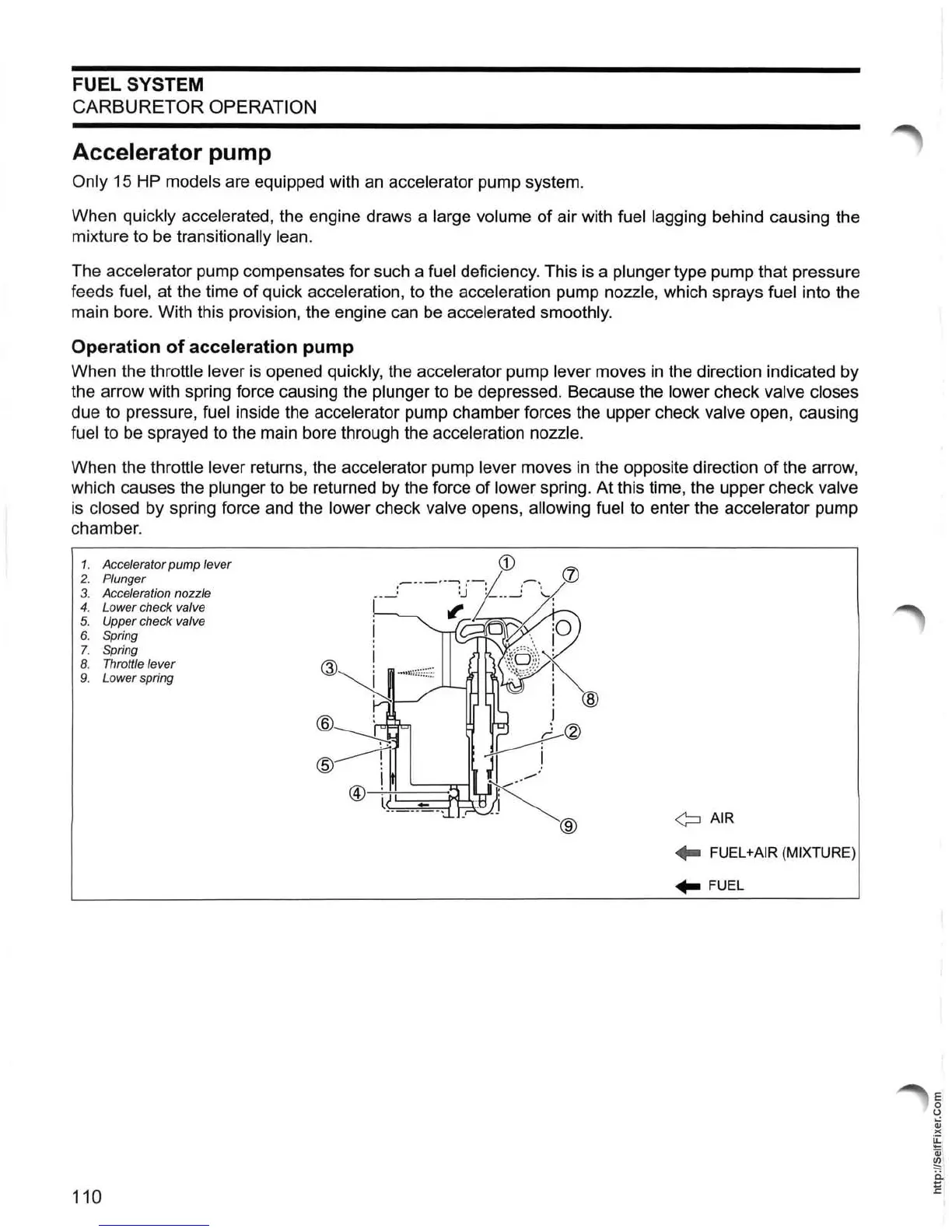

Accelerator pump

Only 15 HP models are equipped with an accelerator pump system.

When

quickly accelerated, the engine draws a large volume

of

air with fuel lagging behind causing the

mixture to be transitionally

lean.

The accelerator pump compensates for such a fuel deficiency. This is a plunger type pump that pressure

feeds

fuel, at the time of quick acceleration, to the acceleration pump nozzle, which sprays fuel into the

main bore. With this provision, the engine can

be

accelerated smoothly.

Operation

of

acceleration pump

When the throttle lever is opened quickly, the accelerator pump lever moves

in

the direction indicated by

the arrow with spring force causing the

plunger to be depressed. Because the lower check valve closes

due to pressure,

fuel inside the accelerator pump chamber forces the upper check valve open, causing

fuel to be sprayed to the main bore through the acceleration nozzle.

When the

throttle lever returns, the accelerator pump lever moves

in

the opposite direction of the arrow,

which causes the

plunger to

be

returned by the force of lower spring. At this time, the upper check valve

is closed by spring force and the lower check valve opens, allowing fuel to enter the accelerator pump

chamber.

1. Accelerator pump lever

2. Plunger

3. Acceleration nozzle

4. Lower check valve

5. Upper check valve

6. Spring

7.

Spring

8. Throttle lever

9. Lower spring

110

¢=I AIR

...

FUEL +AIR (MIXTURE)

...

FUEL

E

o

o

:;j

)(

u::

~

!

(/)

1

::::

i::i.

~

Loading...

Loading...