/

POWERHEAD

TEST PROCEDURES

TEST PROCEDURES

Compression

Testing

Start and run outboard until it achieves operating

temperature, then shut

OFF.

Remove lower side covers. Refer to SIDE COVER

on

p.

180.

Remove spark plugs

Advance throttle linkage to

WOT.

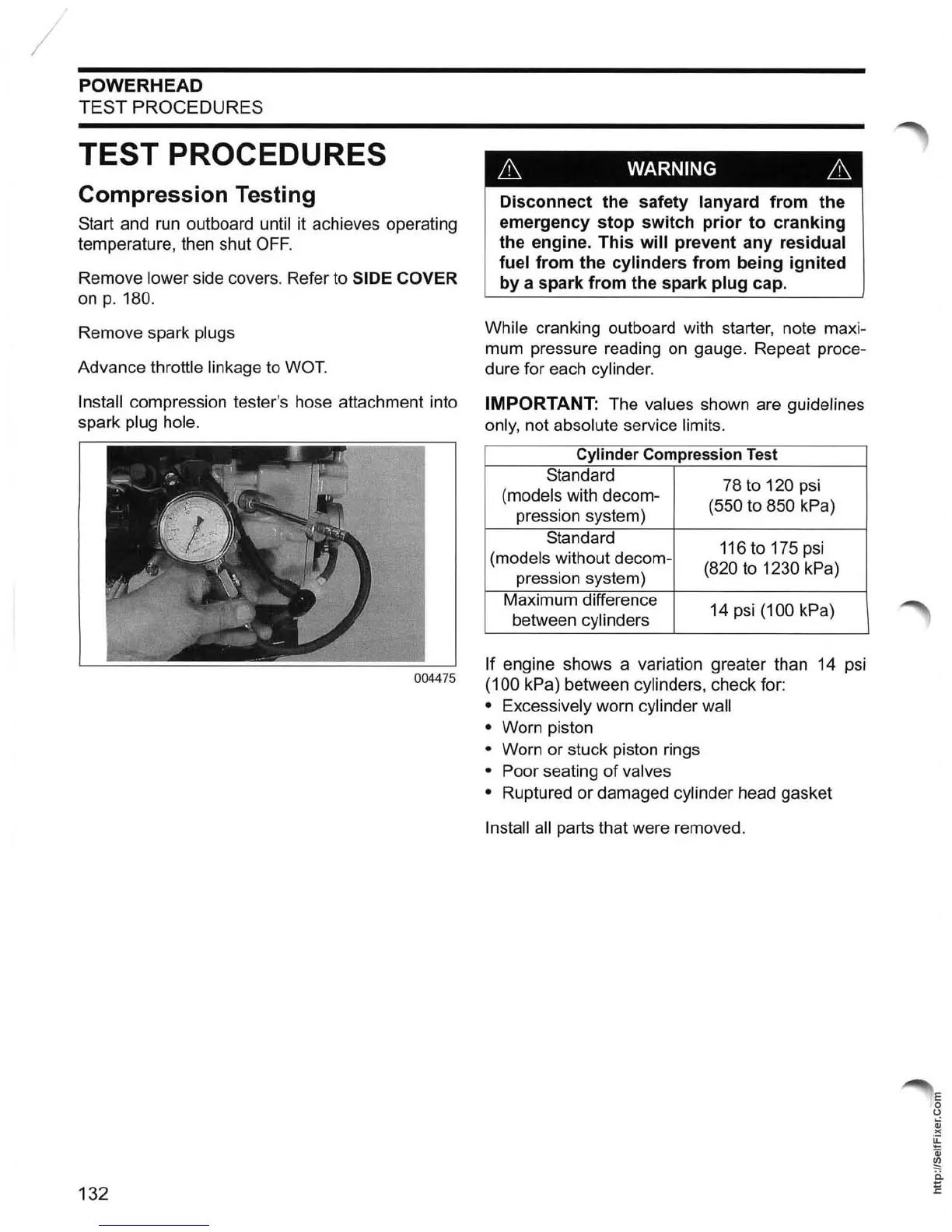

Install compression tester's hose attachment into

spark

plug hole.

004475

132

ill

WARNING

ill

Disconnect

the

safety lanyard

from

the

emergency

stop

switch

prior

to

cranking

the engine.

This

will

prevent

any

residual

fuel

from

the

cylinders

from

being

ignited

by

a

spark

from

the

spark

plug

cap.

While cranking outboard with starter, note maxi-

mum pressure reading

on

gauge. Repeat proce-

dure for each

cylinder.

IMPORTANT: The values shown are guidelines

only,

not absolute service limits.

Cylinder

Compression

Test

Standard

78 to

120 psi

(models with decom-

(550 to 850 kPa)

pression system)

Standard

116

to 175

psi

(models without decom-

(820 to 1230 kPa)

pression system)

Maximum difference

14

psi (100 kPa)

between cylinders

If

engine shows a variation greater than

14

psi

(100 kPa) between cylinders, check for:

• Excessively worn cylinder wall

•

Worn piston

• Worn or stuck piston rings

• Poor seating

of

valves

• Ruptured or damaged cylinder head gasket

Install all parts that were removed.

Loading...

Loading...