For best anode performance:

• Replace all anodes that have eroded or disinte-

grated to two-thirds of their

original size.

• Do not paint or apply protective coatings to

anodes or anode fasteners.

• Avoid using metal-based antifouling paint

on

the

boat or outboard.

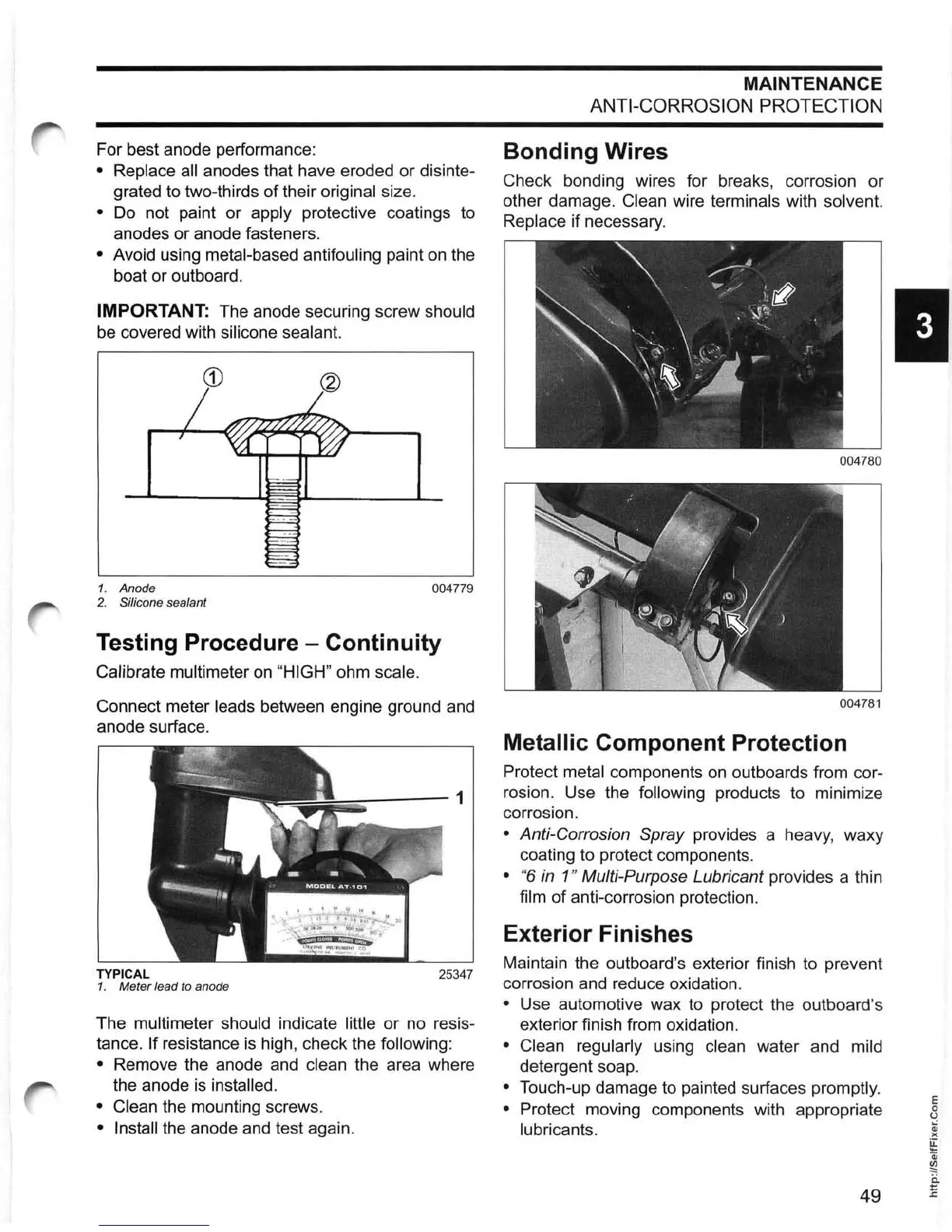

IMPORTANT: The anode securing screw should

be covered with silicone sealant.

1.

Anode

004779

2.

Silicone sealant

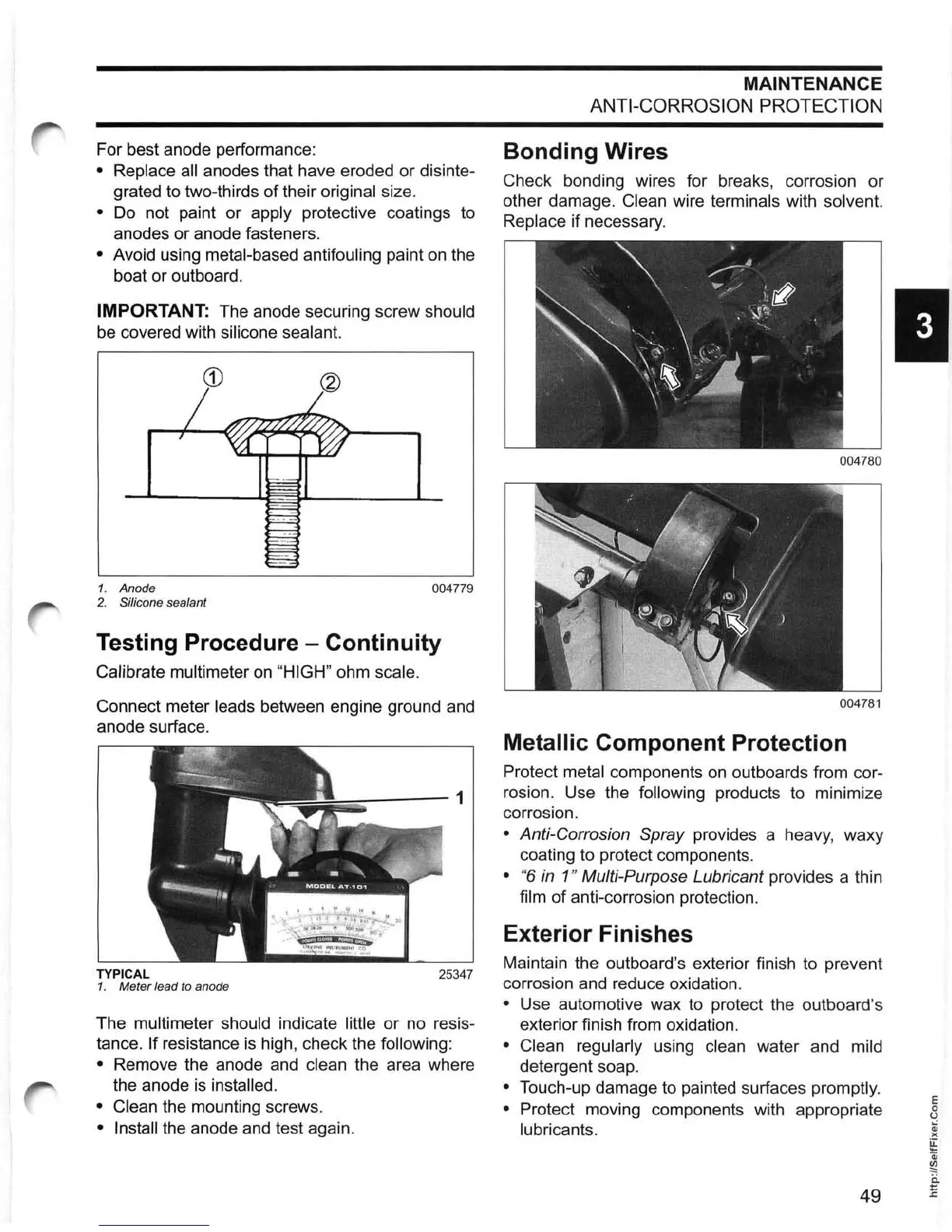

Testing Procedure - Continuity

Calibrate multimeter

on

"HIGH" ohm scale.

Connect meter leads between engine ground and

anode surface.

...

:;;--

--1

TYPICAL

25347

1. Meter lead

to

anode

The multimeter should indicate little or no resis-

tance.

If resistance is high, check the following:

•

Remove the anode and clean the area where

the anode

is

installed.

• Clean

the mounting screws.

• Install the anode and test again.

MAINTENANCE

ANTI-CORROSION PROTECTION

Bonding Wires

Check bonding wires for breaks, corrosion

or

other damage. Clean wire terminals with solvent.

Replace

if necessary.

004780

004781

Metallic Component Protection

Protect metal components

on

outboards from cor-

rosion. Use the

following products to minimize

corrosion.

• Anti-Corrosion Spray provides a heavy, waxy

coating to protect components.

• "6

in

1" Multi-Purpose Lubricant provides a thin

film of anti-corrosion protection.

Exterior Finishes

Maintain the outboard's exterior finish

to

prevent

corrosion and reduce oxidation.

• Use automotive wax

to

protect the outboard's

exterior finish from oxidation.

• Clean regularly using clean water and mild

detergent soap.

• Touch-up damage to painted surfaces promptly.

•

Protect moving components with appropriate

lubricants.

49

Loading...

Loading...