MAINTENANCE

10-HOUR INSPECTION

10-HOUR INSPECTION

IMPORTANT: All Johnson outboard owners are

encouraged to return their new engines to

an

authorized dealer for a mechanical check.

This check

should

be

performed after approxi-

mately

10

operating hours. The cost of this check

should

be

figured at local dealer labor rates and

paid for by the engine owner.

The

10 hour inspection should check:

• Anticorrosion anodes functionality

•

Water intake screens

• Overboard water pump indicator

• Steering operation

• Throttle and shift operation

• Emergency stop circuit and lanyard functionality

• Fuel

system components, repair any leaks

• Fuel filter, eliminate

any contamination

• Fasteners, tighten loose components

• Air silencer, clean and inspect

• Thermostat operation

• Engine to transom mounting hardware

• Electrical and ignition wires and connections

• Synchronization and linkage adjustments

48

ANTI-CORROSION

PROTECTION

Sacrificial Anodes

Galvanic corrosion occurs

in

fresh or salt water.

Salt, brackish, and polluted water can accelerate

corrosion. "Sacrificial" anodes are intended to pro-

tect the underwater

metal components

of

the out-

board from

galvanic corrosion.

Outboards are equipped with

sacrificial anodes.

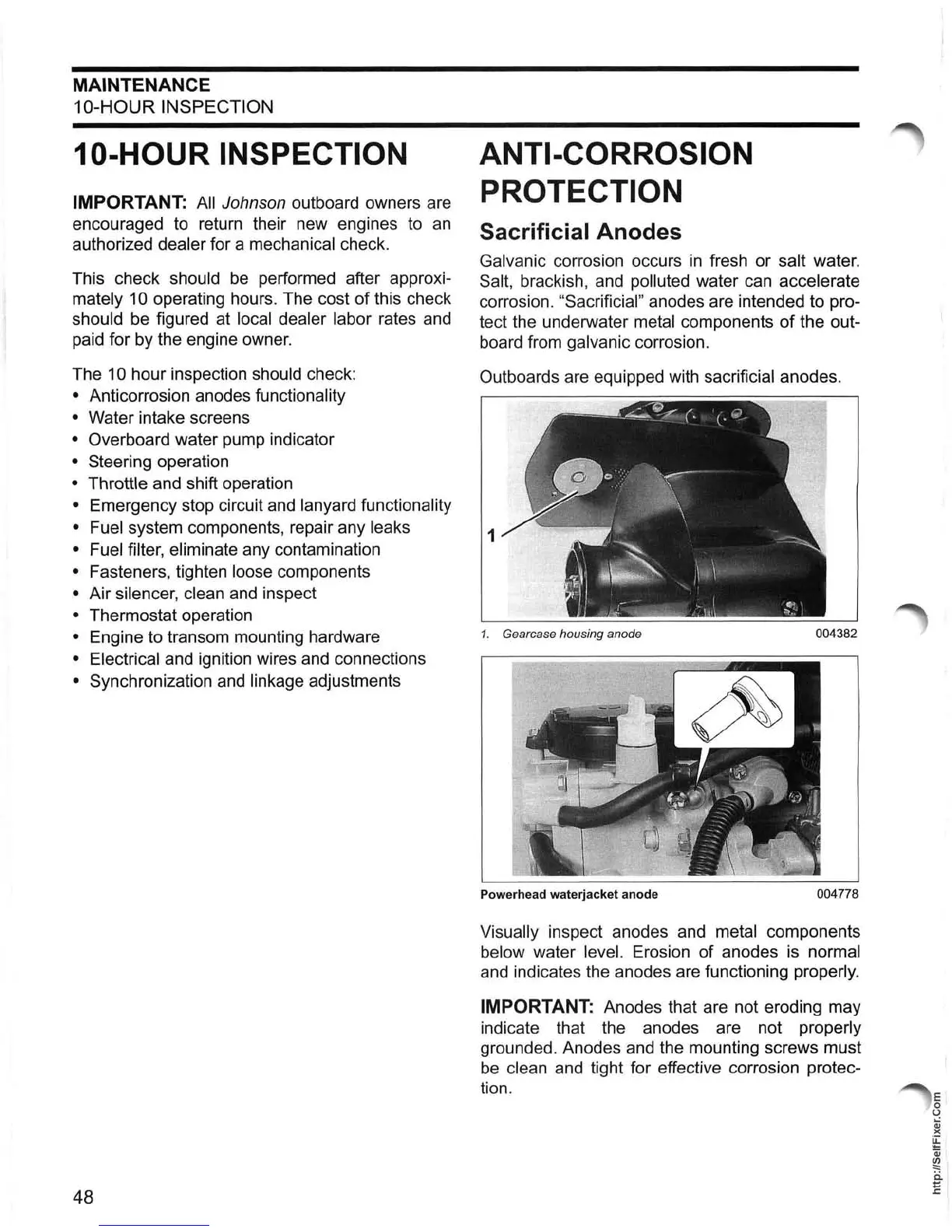

1

1.

Gearcase housing anode 004382

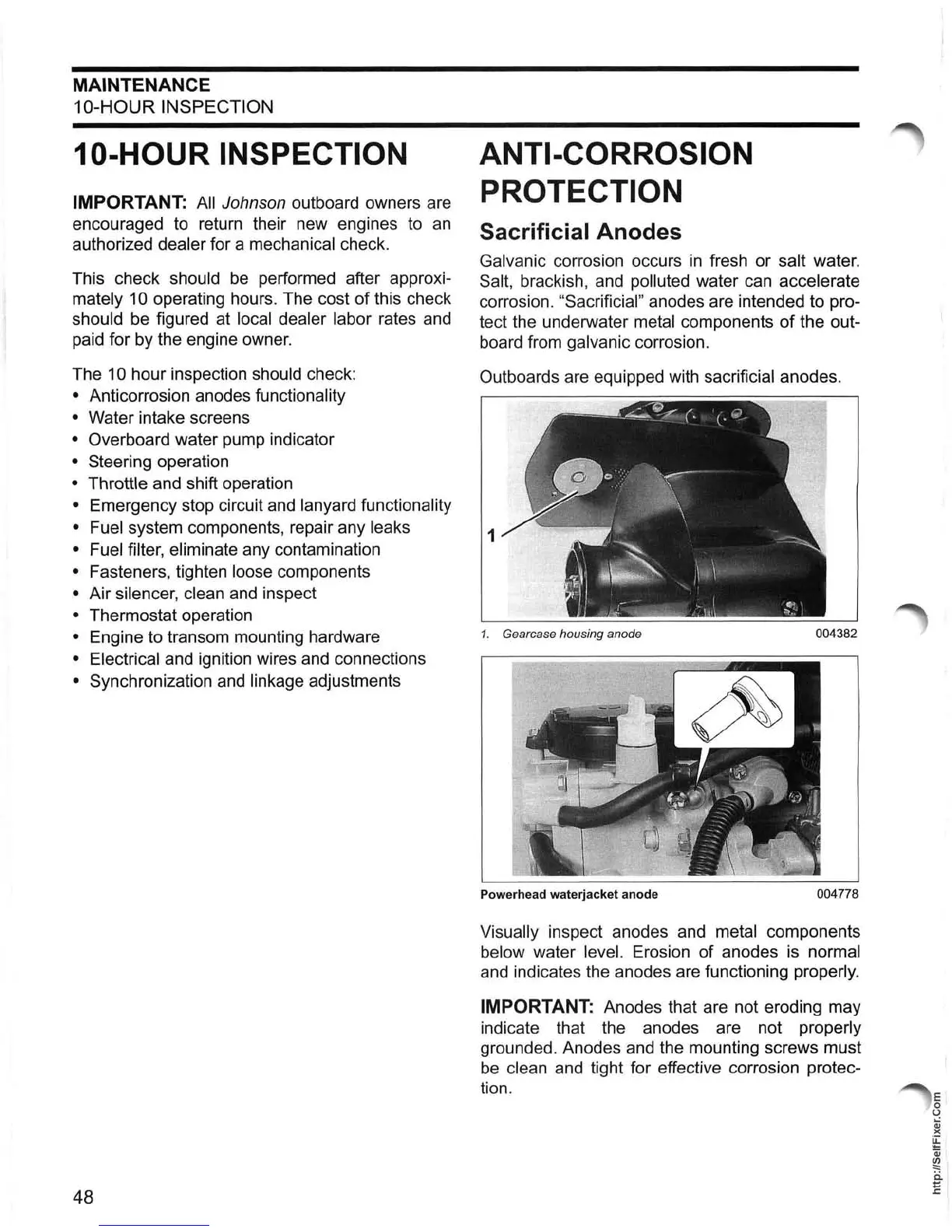

Powerhead

waterjacket

anode

004778

Visually inspect anodes and metal components

below water level. Erosion of anodes

is

normal

and indicates the anodes are functioning properly.

IMPORTANT: Anodes that are not eroding may

indicate that the anodes are not

properly

grounded. Anodes and the mounting screws must

be

clean and tight for effective corrosion protec-

tion.

E

o

U

Qj

)(

~

Qj

~

ii

E

Loading...

Loading...