To

check for water contamination, drain lubricant

into a suitable glass container. Allow the drained

oil to settle for a minimum of one hour to deter-

mine if there

is

an

abnormal amount of water

in

the oil. Some gearcase lubricants are designed to

mix with a

small amount of water from normal

water vapor condensation within the gearcase.

Refer to

LEAK TEST

on

p.

199.

Overheated

lubricant will give the lubricant a black

color

and burned

odor.

Internal gearcase inspection

is

recommended

when

lubricant

is

contaminated or shows signs of

failure.

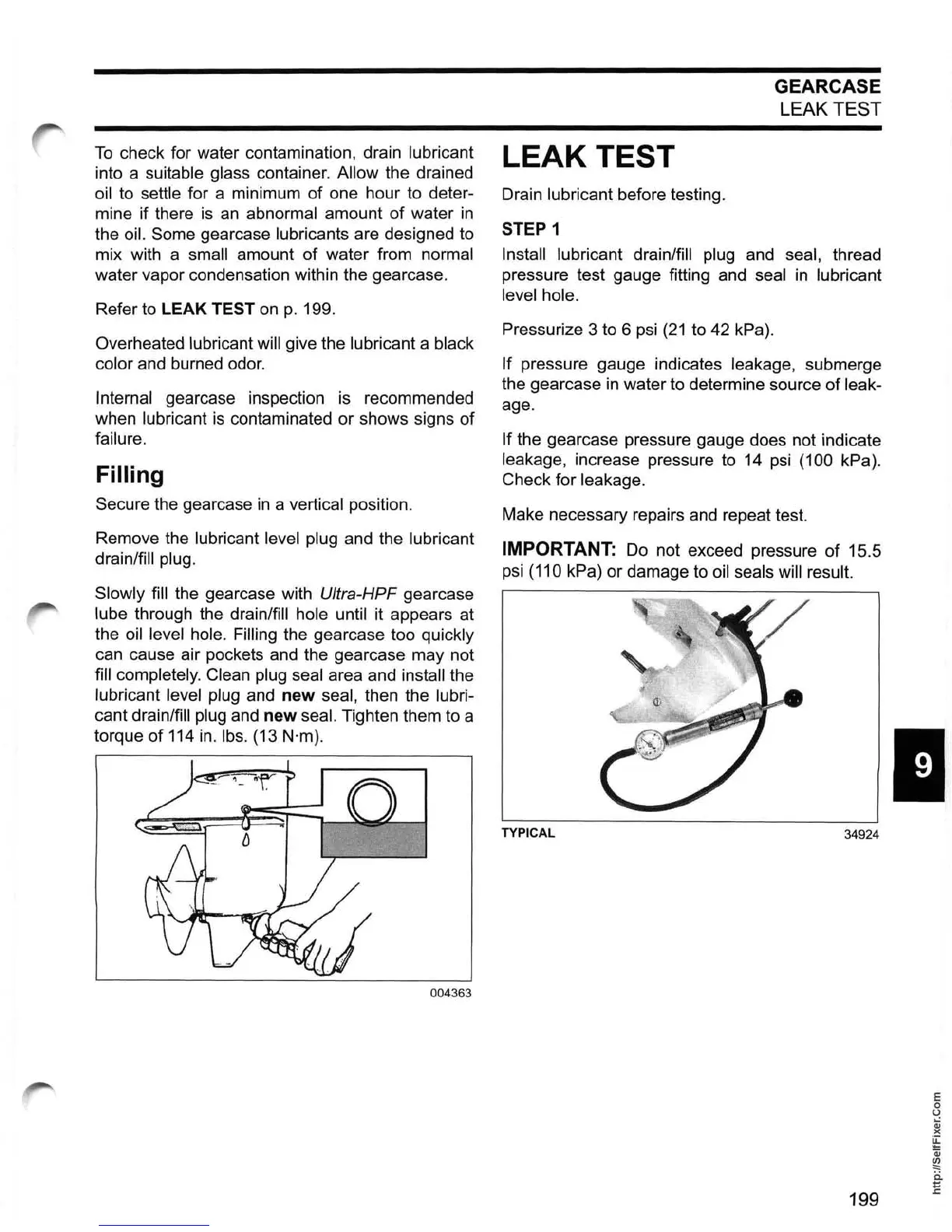

Filling

Secure the gearcase

in

a vertical position.

Remove the

lubricant level plug and the lubricant

drain/fill plug.

Slowly fill

the gearcase with Ultra-HPF gearcase

lube through the drain/fill hole until it appears at

the oil level hole. Filling the gearcase too quickly

can cause air pockets and the gearcase may not

fill completely. Clean plug seal area and install the

lubricant level plug and new seal, then the lubri-

cant drain/fill plug and new seal. Tighten them to a

torque

of

114

in.

Ibs

. (13 N·m).

004363

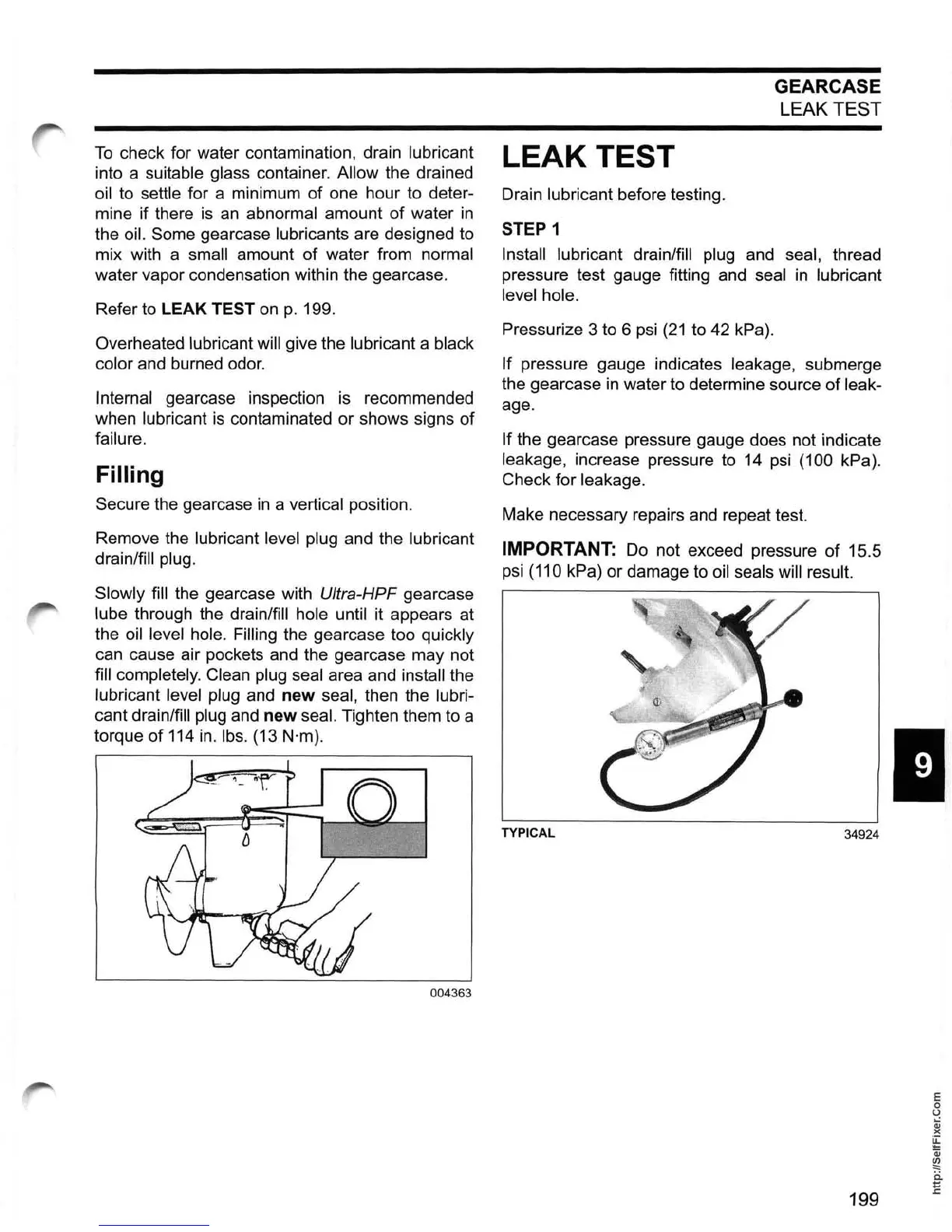

LEAK TEST

Drain lubricant before testing.

STEP 1

GEARCASE

LEAK TEST

Install lubricant drain/fill plug and seal, thread

pressure test gauge fitting and

seal

in

lubricant

level hole.

Pressurize 3 to 6 psi

(21

to 42 kPa).

If pressure gauge indicates leakage, submerge

the gearcase

in

water to determine source

of

leak-

age.

If the gearcase pressure gauge does not indicate

leakage, increase pressure to

14

psi

(100 kPa).

Check for

leakage.

Make necessary repairs and repeat test.

IMPORTANT:

Do

not exceed pressure

of

15.5

psi

(110

kPa) or damage to oil seals will result.

TYPICAL

34924

199

I

E

o

U

Qj

)(

~

Qj

~

ii

E

Loading...

Loading...