FUEL SYSTEM

CARBURETOR SERVICE

Cleaning and Inspection

Carburetor must

be

completely disassembled.

Use a clean bristle brush to remove gum or var-

nish deposits.

Thoroughly clean components with

Carburetor

and

Choke Cleaner.

IMPORTANT:

Do

not clean carburetor or its

components by submerging

in

strong carburetor

cleaner or hot soaking tank. Strong cleaners might

damage components or remove

sealing com-

pounds.

Flush all carburetor holes and passages with a

small syringe filled with isopropyl alcohol. Blow

passages and carburetor dry with compressed air

of not more than 25

psi

(172 kPa). When drying

passages, direct the flow of shop air opposite to

the direction

of

fuel flow.

IMPORTANT: Wire or small drill bits must not

be

used to clean carburetor orifices and jets.

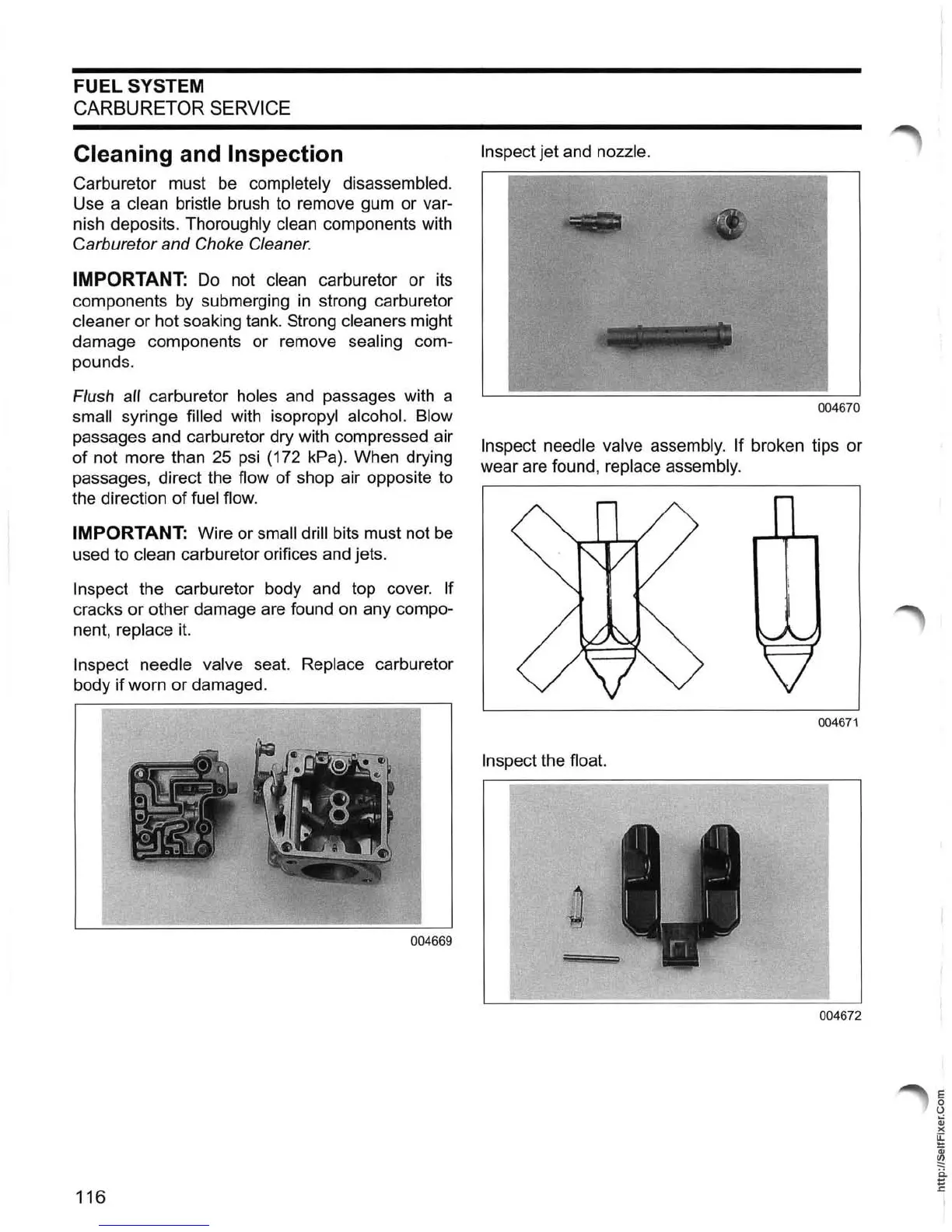

Inspect the carburetor body and top cover. If

cracks or other damage are found

on

any compo-

nent,

replace it.

Inspect needle valve seat. Replace carburetor

body if worn or damaged.

004669

116

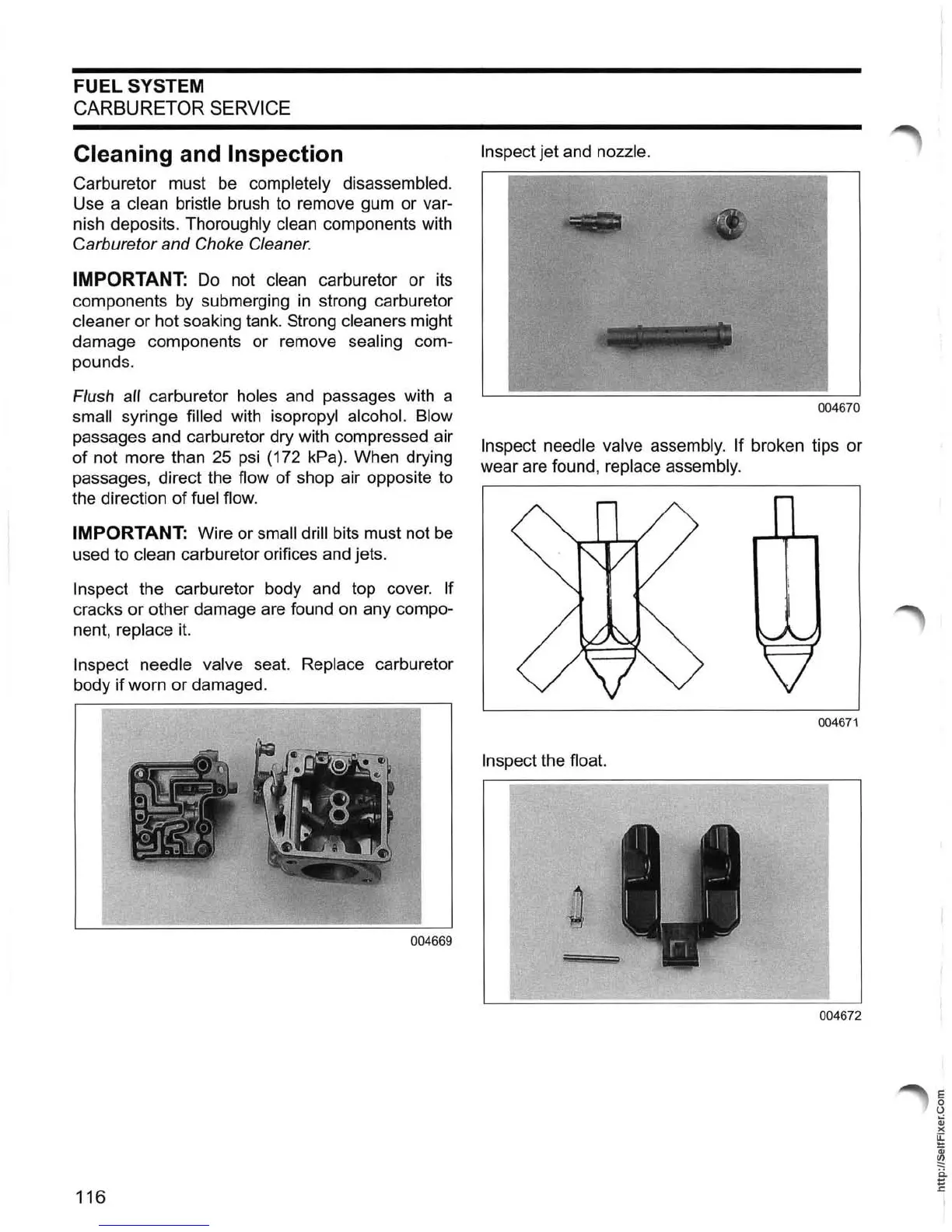

Inspect jet and nozzle.

004670

Inspect needle valve assembly. If broken tips or

wear are found,

replace assembly.

004671

Inspect the float.

004672

E

o

u

oj

)(

~

;;j

:::::

i::i.

~

Loading...

Loading...