Assembly

Assembly

is

reverse order of disassembly with

special attention to the following steps:

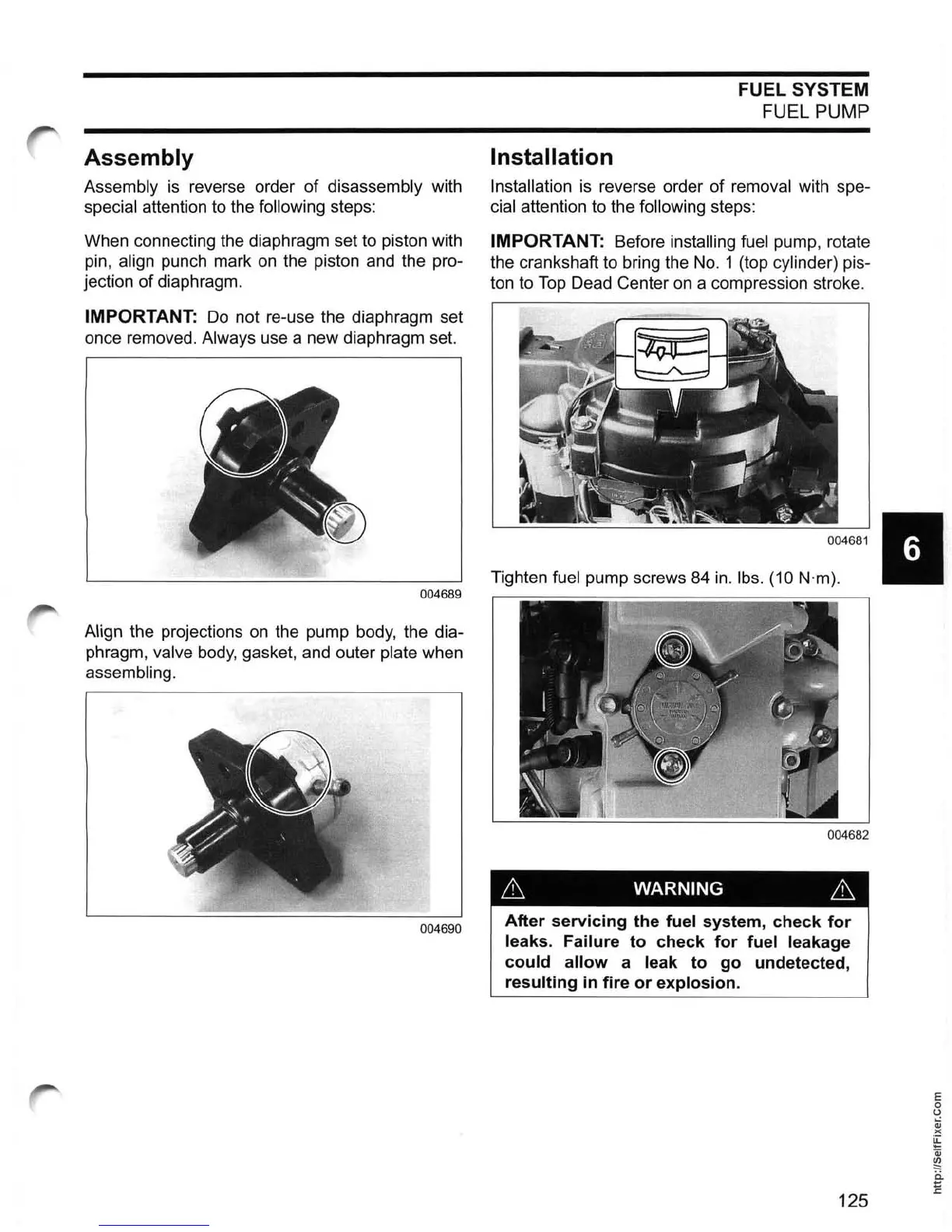

When connecting the diaphragm set to piston with

pin,

align punch mark

on

the piston and the pro-

jection of diaphragm.

IMPORTANT:

Do

not

re

-use the diaphragm set

once removed.

Always use a new diaphragm set.

004689

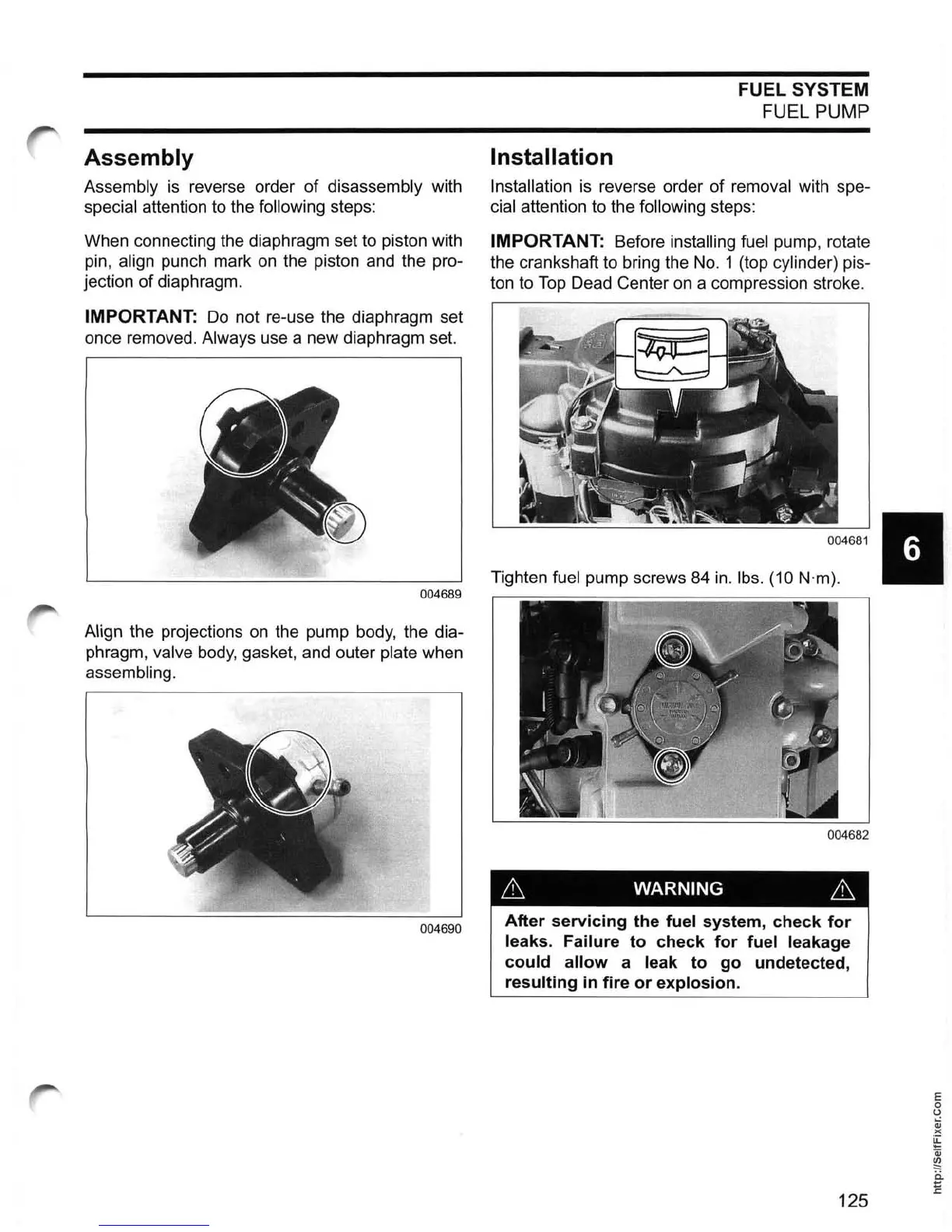

Align the projections

on

the pump body, the dia-

phragm,

valve

body,

gasket, and outer plate when

assembling.

004690

Installation

FUEL SYSTEM

FUEL PUMP

Installation is reverse order of removal with spe-

cial attention to the following steps:

IMPORTANT: Before installing fuel pump, rotate

the crankshaft to bring the

No

. 1 (top cylinder) pis-

ton to

Top

Dead Center

on

a compression stroke.

004

68

1

Tighten fuel pump screws 84

in.

Ibs. (10 N·m).

0

04

682

& WARNING

ill

After

servicing

the fuel system,

check

for

leaks. Failure

to

check

for

fuel leakage

could

allow

a leak

to

go

undetected,

resulting

in

fire

or

explosion

.

125

II

Loading...

Loading...