GEARCASE

PROPELLER

PROPELLER

Inspection

Carefully check the propeller and outboard for the

following conditions:

• Damaged blades and signs of propeller cavita-

tion

• Spun or overheated inner hub

• Inadequate lubricant

•

Damage to outer hub area

• Correct size

• Check for bent or damaged propeller shaft

Installation

Refer to

Propeller

Hardware Installation

on

p.44.

6 WARNING 6

When

servicing

the propeller, always

shift

the

outboard

to

NEUTRAL and

twist

and

remove

all

spark

plug

leads

so

the

engine

cannot

be started accidentally.

198

LUBRICANT

Draining

& WARNING &

Gearcase

lubricant

may

be

under

pressure

and/or

hot.

If

plug

is

removed

from

a

recently operated outboard, take

precau-

tions

to

avoid

injury.

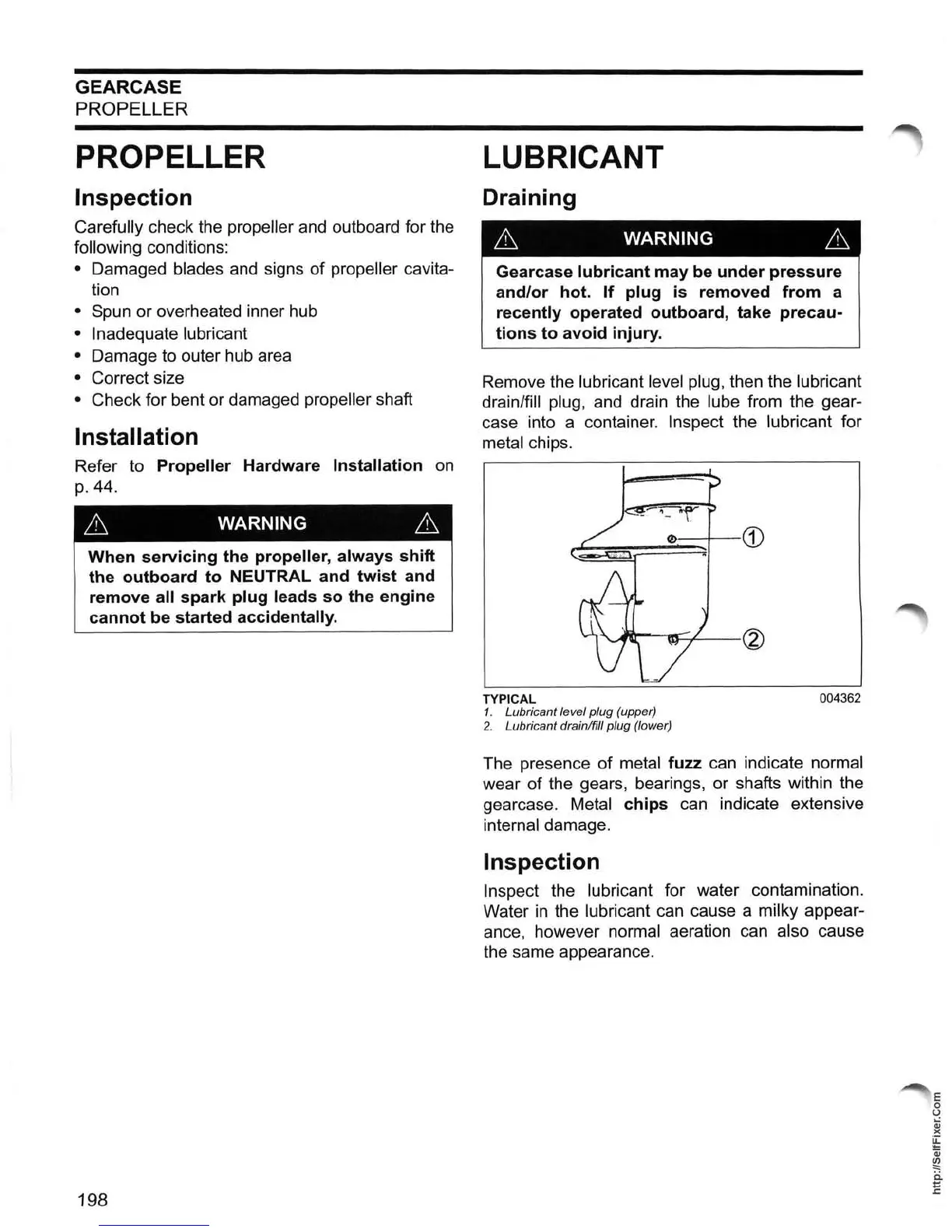

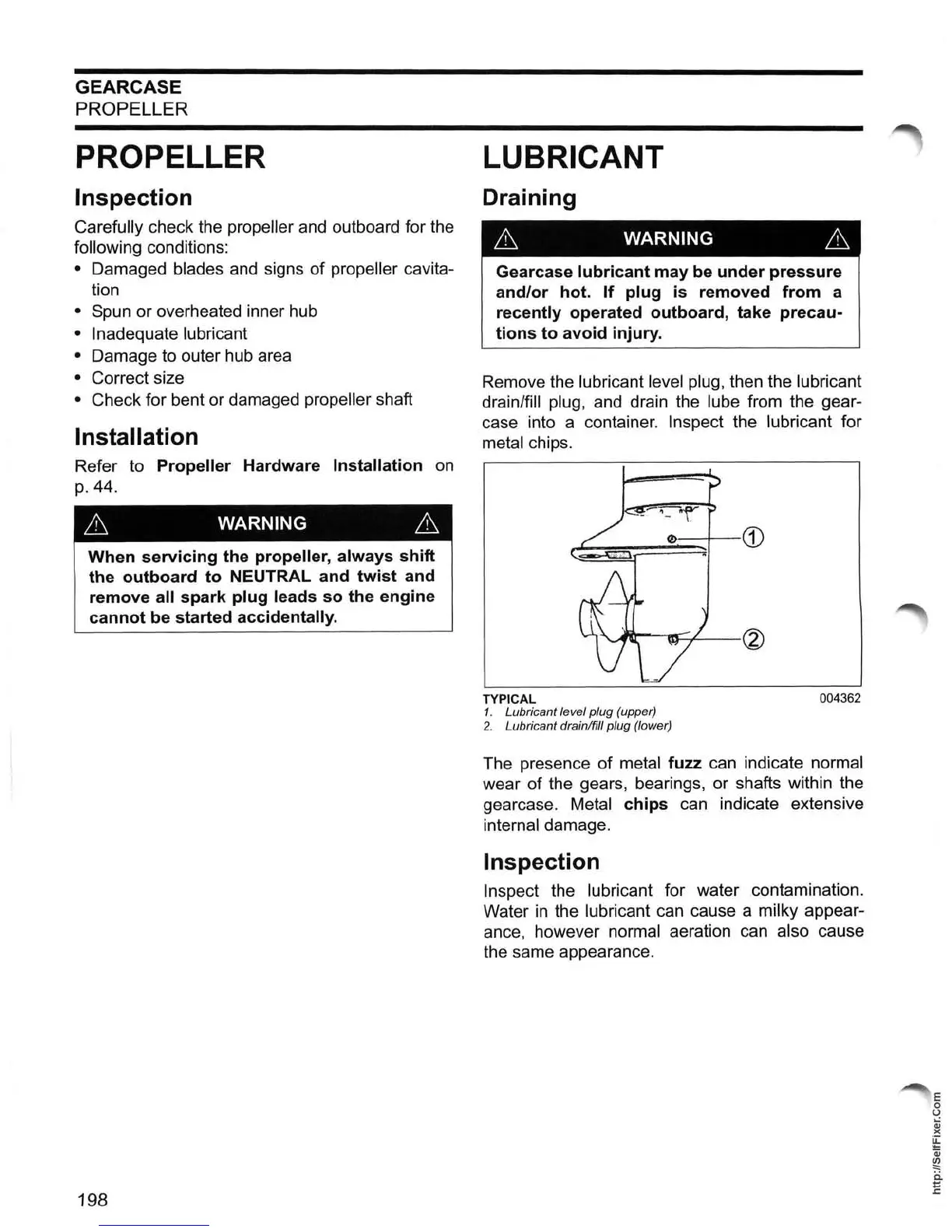

Remove the

lubricant level plug, then the lubricant

drain/fill plug,

and drain the lube from the gear-

case into a container. Inspect the lubricant for

metal chips.

TYPICAL

004362

1. Lubricant level plug (upper)

2. Lubricant drain/fill plug (lower)

The presence of metal fuzz can indicate normal

wear

of

the gears, bearings, or shafts within the

gearcase.

Metal

chips

can indicate extensive

internal damage.

Inspection

Inspect the lubricant for water contamination.

Water

in

the lubricant can cause a milky appear-

ance, however normal aeration can also cause

the same appearance.

E

o

U

Qj

)(

~

Qj

~

ii

E

Loading...

Loading...