FUEL SYSTEM

CARBURETOR SERVICE

Installation

Installation

is

reverse order of removal with spe-

cial attention to the following steps:

IMPORTANT:

Do

not re-use gasket. Air leakage

will

cause a lean air/fuel mixture which

can

result

in

severe engine damage.

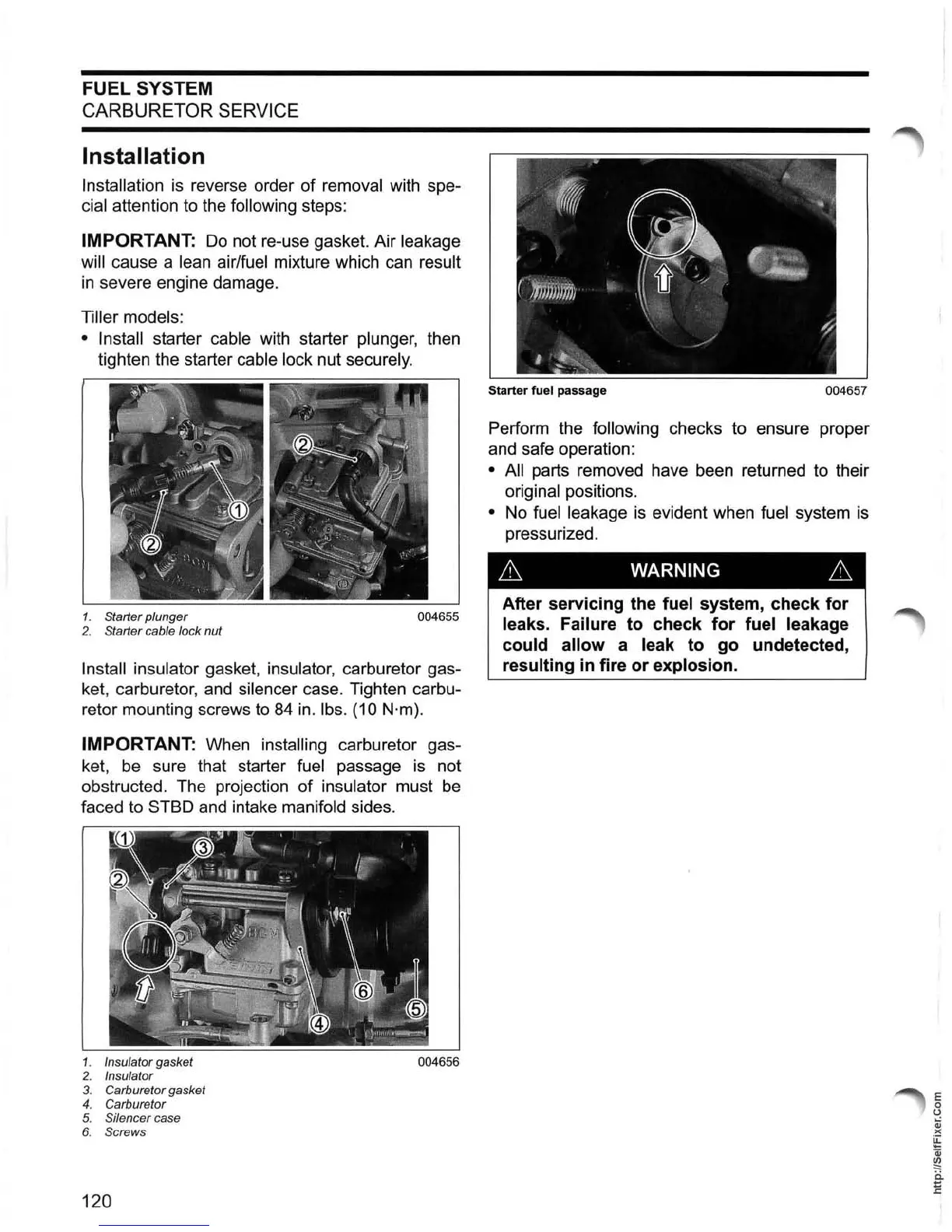

Tiller models:

• Install

starter cable with starter plunger, then

tighten the starter

cable lock nut securely.

1. Starter plunger 004655

2.

Starter cable lock nut

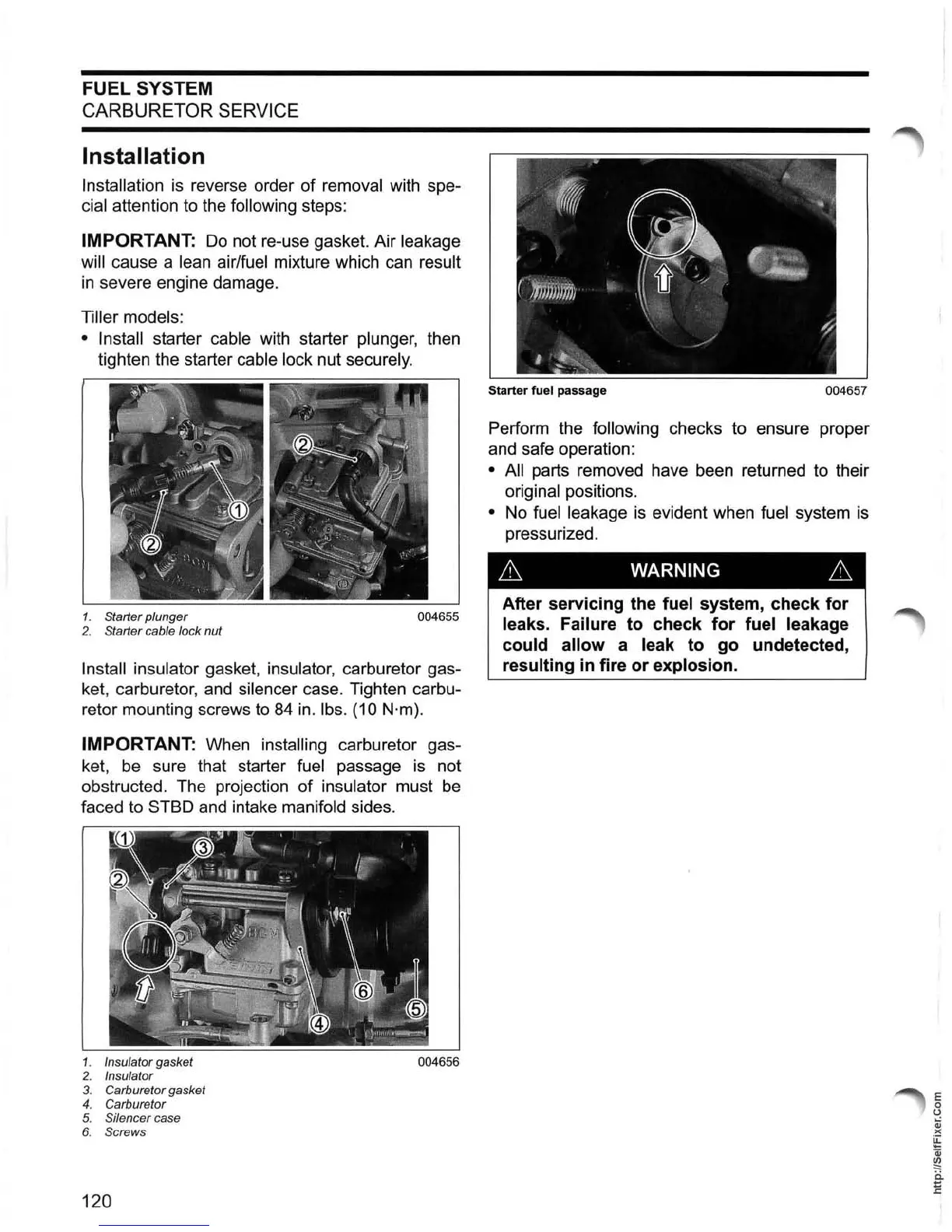

Install insulator gasket, insulator, carburetor gas-

ket, carburetor, and

silencer case. Tighten carbu-

retor mounting screws to

84

in.

Ibs. (10 N·m).

IMPORTANT: When installing carburetor gas-

ket,

be

sure that starter fuel passage

is

not

obstructed. The projection of

insulator must

be

faced to STSD

and

intake manifold sides.

1. Insulator gasket

004656

2. Insulator

3. Carburetor gasket

4.

Carburetor

5. Silencer case

6. Screws

120

Starter fuel passage

004657

Perform the following checks to ensure proper

and safe operation:

• All parts removed have been returned to their

original positions.

• No fuel leakage

is

evident when fuel system

is

pressurized.

& WARNING &

After servicing the fuel system, check for

leaks. Failure

to

check for fuel leakage

could allow

a leak to go undetected,

resulting

in

fire or explosion.

Loading...

Loading...