POWERHEAD

CYLINDER/CRANKCASE/PISTON ASSEMBLY

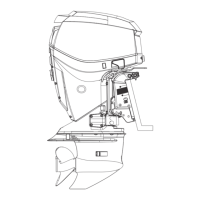

Measure the cylinder bore

in

the thrust and axial

directions at three depth positions A,

B,

and

C.

The difference between the two depth measure-

ments

;s

the cylinder bore taper.

The difference between the

axial and transverse

measurements

is

the cylinder bore out-of-round.

The service

limit for cylinder bore wear as 0.0022

in.

(0

.055 mm). If either taper or out-of-round mea-

surement exceeds service

limit, rebore or replace

cylinder.

- ,

.{

;ja

' ,

~

"".

• I

~

.

,

,

~Jl

004570

®

®

.

~©

---7J0C

'

!!II

EB

004571

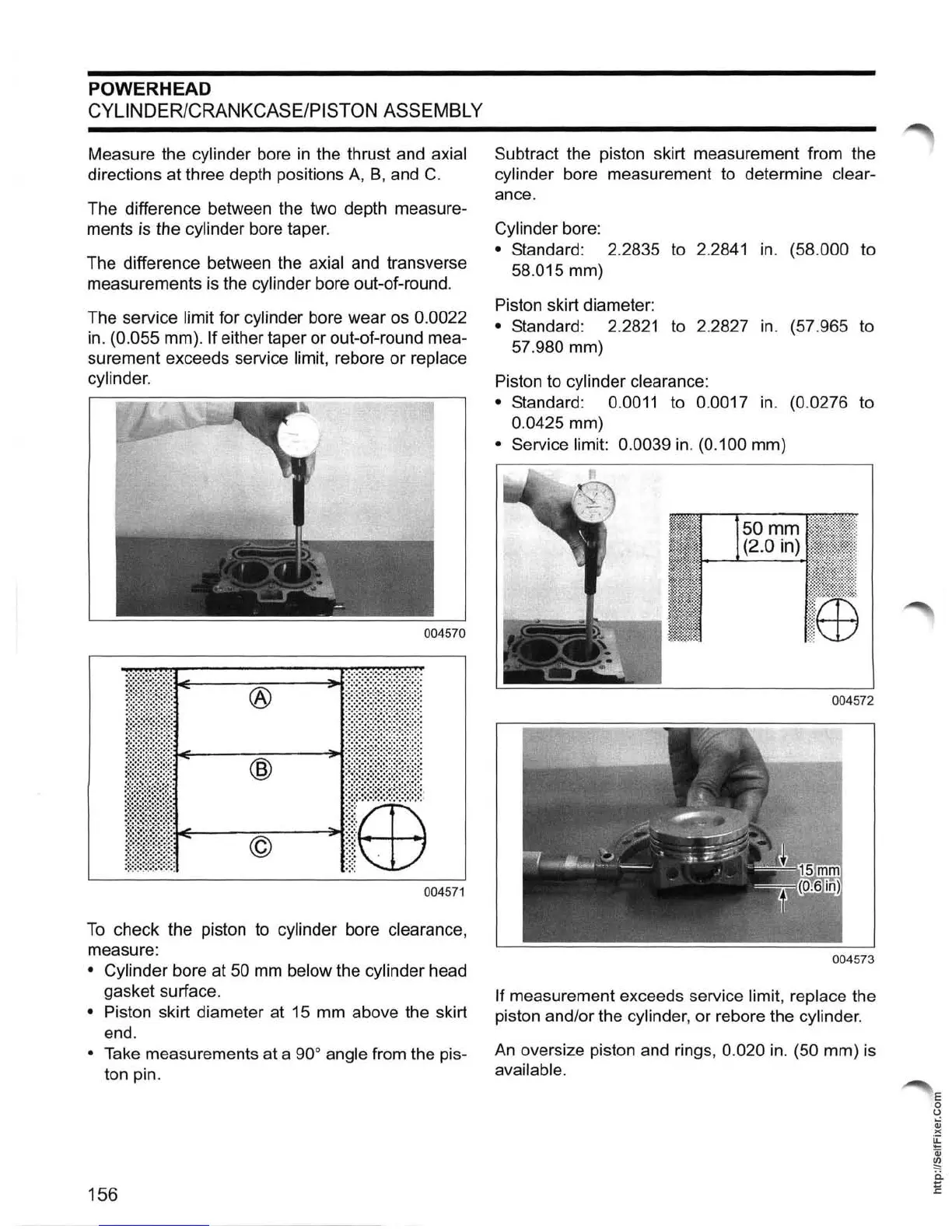

To

check the piston

to

cylinder bore clearance,

measure:

• Cylinder bore at

50

mm below the cylinder head

gasket surface.

• Piston skirt diameter at 15 mm above the skirt

end.

• Take measurements at a 90

0

angle from the pis-

ton pin.

156

Subtract the piston skirt measurement from the

cylinder bore measurement to determine clear-

ance.

Cylinder bore:

• Standard: 2.2835 to 2.

2841

in

. (58.000 to

58.015 mm)

Piston skirt diameter:

• Standard: 2.2821 to 2.2827

in.

(57.965 to

57.980 mm)

Piston to cylinder clearance:

• Standard: 0.

0011

to 0.0017

in

. (0.0276 to

0.0425 mm)

• Service limit: 0.0039

in

. (0.100 mm)

50mm

(2.0 in)

00

4572

0

04

57

3

If measurement exceeds service limit, replace the

piston and/or the

cylinder, or rebore the cylinder.

An

oversize piston and rings, 0.020

in

. (50 mm) is

available.

Loading...

Loading...