ELCB

H172203_1_001 57 / 234

8.4.1 Protection

The power amplifier providing the lock current for the H0 coil is protected against short

circuits (limiting the output current) and over temperature.

8.4.2 Lock Software Architecture

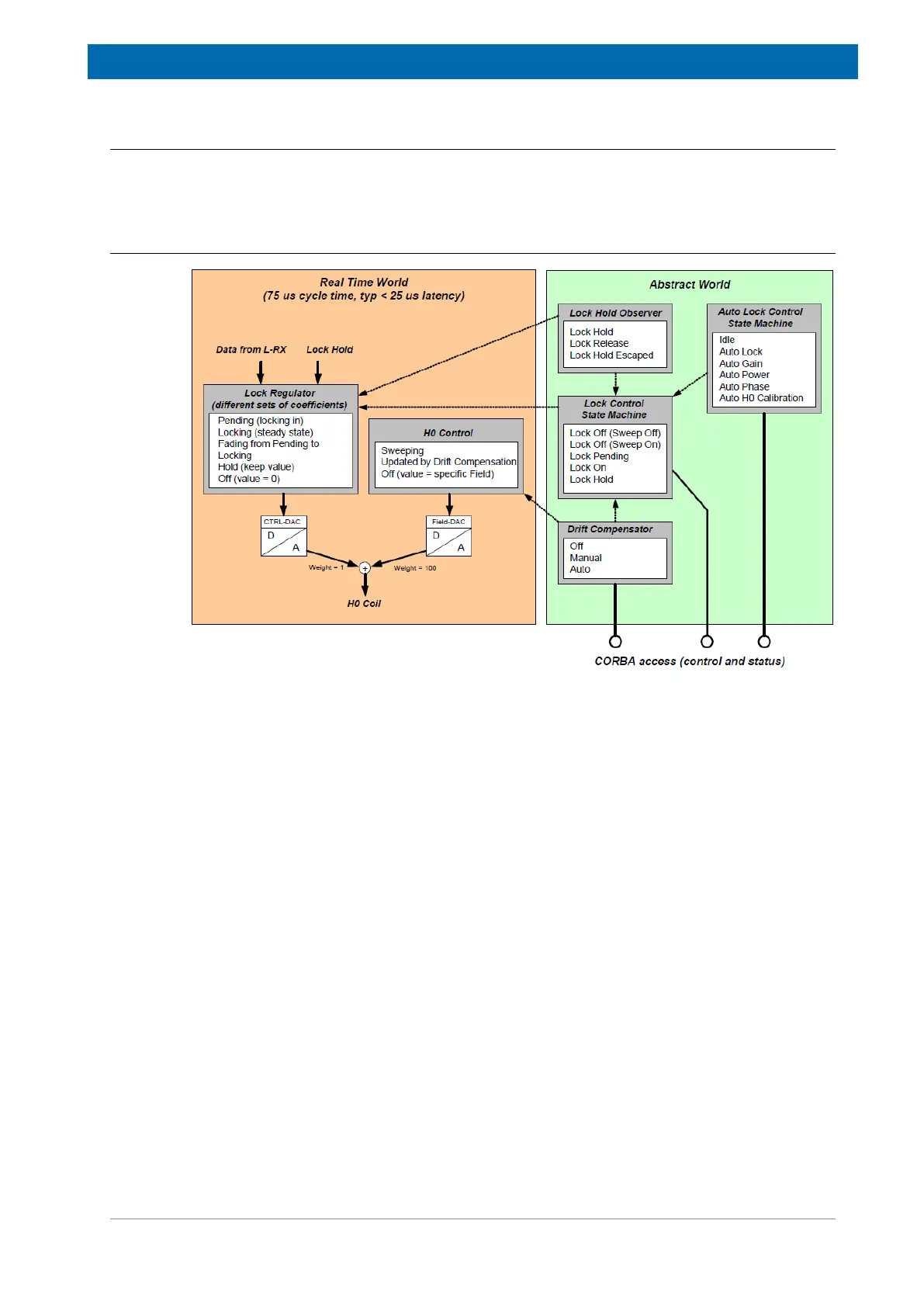

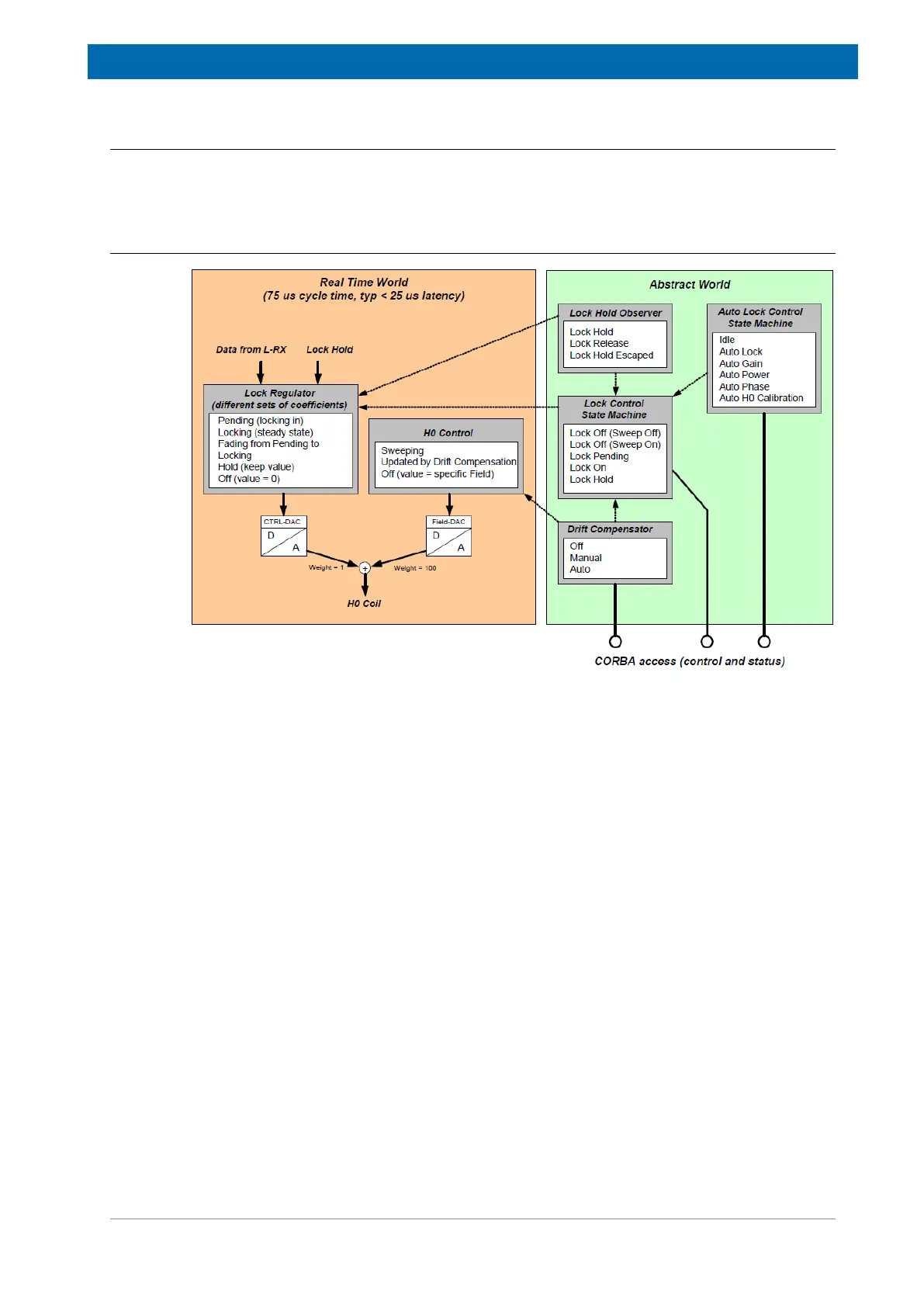

Figure8.3: Abstract Control Domain and Real Time Domain

One part of the Lock software runs in „real time“ mode: An interrupt service routine is called

every 75 microseconds. This routine reads the Lock receiver data and evaluates the

corresponding Ctrl-DAC and Field-DAC values, which are applied by the Control FPGA to the

hardware. The typical delay time from arrival of the receiver data to the completion of the

DAC write cycle is less than 25 micro seconds.

On the other hand, there is a more abstract part, modelling the Lock behavior and controlling

higher level functions, e. g. locking in, selecting the appropriate set of Regulator Coefficients,

compensating the drift and so on. This part of the software is connected with the CORBA

interface - it handles requests from the TopSpin application and notifies about state changes

(e. g. Lock Hold). It is non-real time and may react with a delay of several milliseconds.

The Lock Hold signal affects directly the regulator, which guarantees extremely short reaction

times. An external Lock Hold Observer examines every 20 milliseconds the Lock Hold state.

If the regulator runs in Lock Hold mode or if a short Lock Hold pulse has been active in the

mean time (Lock Hold Escaped) then the Lock Hold Observer updates the Lock Control State

Machine and notifies the registered clients - even the shortest Lock Hold pulses are indicated

on the keyboard (if connected) and in the TopSpin application.

Loading...

Loading...