44 Magellan™ 9300i / 9400i Scanners

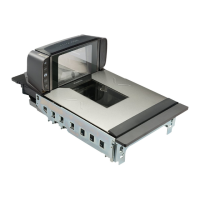

3. Lower the unit into the counter opening, ensuring that none of the cables

are pinched, pierced or crimped.

4. View the bubble level (if present

1

) located on the scanner's spider assem-

bly to ensure the scanner is level. As shown in the insert of Figure 23, the

air bubble should appear fully within the circle indicated. The air bubble

can touch the circle, but must not overlap it. Apply shims beneath the

scanner flange or adjust the leveling feet to allow level installation.

5. Mount the horizontal surface of the All-Weighs Platter flush with the coun-

tertop to encourage slide scanning rather than lifting.

6. Position the centerline of the scanner read area 20.3 - 25.4 cm (8 - 10

inches) from the edge of the checkstand (cashier side).

7. Reinstall the All Weighs™ Platter and verify that it is flush or just below

flush with the countertop. This is necessary to provide smooth scanning

from either direction. Make adjustments as needed to align the platter with

the counter by moving support rails up or down, or consider installing

screws in positions that will allow their use in adjusting the unit’s position.

Ensure that leveling is maintained if adjustments are made.

You have now completed installation and system integration of the scanner or

scanner-scale. At this point, the scale must be calibrated and certified in accor

-

dance with the requirements of your state and/or local requirements. Refer to

Chapter 6. Calibration Procedures for calibration details.

1. The bubble level is present only on certain models.

NOTE

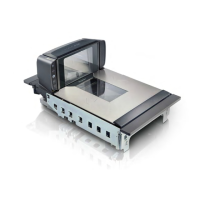

Failure to install a scanning-scale in a stable and level position will

inhibit weighing, calibration and zeroing operations. The platter

MUST make unobstructed contact with all of its supports for proper

weighing operation.

Loading...

Loading...