ENTRON Controls, LLC. • 700120S • Page 143

Before running production quantities of welded parts,

ENTRON recommends destructive testing of the welds.

Set the welding machine to RWMA recommended

standards. Weld the parts. Then clamp one end of the welded

part in a vise and PEEL the other side back against the

weld. Ideally, in low carbon steel, the weld will pull a hole

through one or the other parent materials.

To make the best possible weld for the material to

be welded, use:

1. The LOWEST transformer tap setting,

2. The HIGHEST PERCENT CURRENT setting, and

3. The SHORTEST WELD count setting.

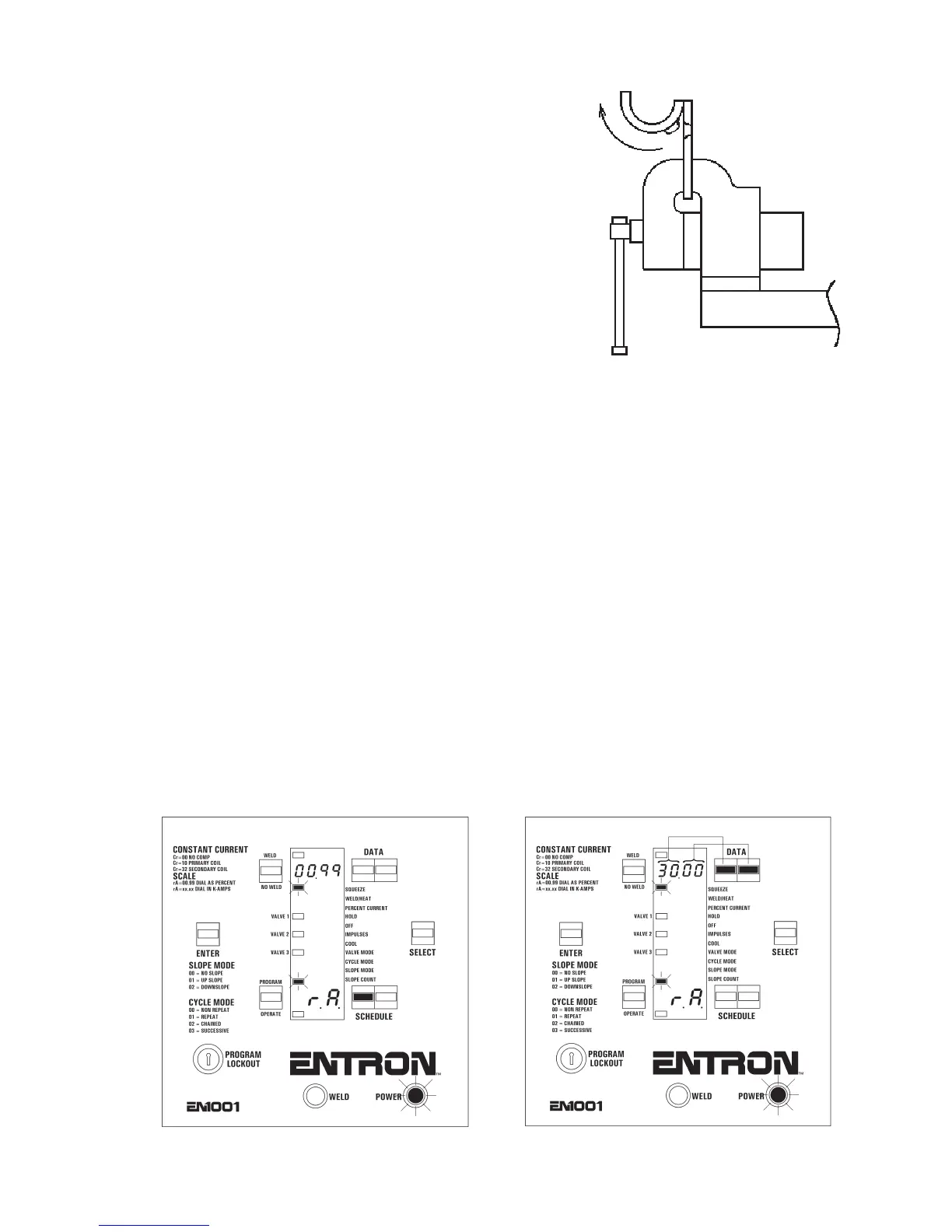

B-2.0 CONSTANT CURRENT PROGRAMMING AND SETUP

(EN1001 only)

Put control in PROGRAM mode, as shown in Figure B-8. Find the EXTENDED FUNCTIONS

by pressing the SELECT push button until

EFEF

EFEF

EF appears in the DATA display. Use SCHEDULE

push buttons to scroll through the EXTENDED FUNCTIONS.

Based on Current Sensor and desired CONSTANT CURRENT mode, program

C.rC.r

C.rC.r

C.r

..

..

. and

rr

rr

r

.A..A.

.A..A.

.A. to

enable CONSTANT CURRENT. For

C.rC.r

C.rC.r

C.r

..

..

.=

3232

3232

32 or

3333

3333

33, only [kA] mode is possible, and

rr

rr

r

.A..A.

.A..A.

.A. must

be programmed according to desired RANGE (see Table 8-1). Programming [%] mode is shown

in Figure B-21, and programming RANGE of 30 kA for [kA] mode is shown in Figure B-22.

For programming four-digit data parameters, the two DATA push buttons are used as follows:

Press right DATA push button to increase by one, press and hold to increase by ten. Press left

DATA push button to increase by 100, and press and hold to increase by 1000.

After selecting and programming desired CONSTANT CURRENT mode, run setup if necessary.

Figure B-20. Destructive test

Figure B-21. Program RANGE for [%] mode

Figure B-22. Program RANGE for [kA] mode

APPENDIX B PROGRAMMING AND SETUP (cont.)

Loading...

Loading...