ENTRON Controls, LLC. • 700120S • Page 149

APPENDIX D

Weldsafe 5000

combination ground fault sensing and ground checking relay for

AC 50-60 Hz manual transgun applications

Weldsafe 5000 Features

‚ 10 mA trip point setting for ground fault sensing

‚ C.T. loop monitoring

‚ 1 single trip point for ground checking

‚ Voltage Build-up Detection

‚ Optional End-of-Line Resistor for crush fault detection

‚ Harmonic filtering

The Weldsafe 5000 combination ground fault current and ground check relay has been designed to provide

sensitive ground fault protection and continuous ground checking for ac, 50-60 Hz manual transguns in accordance

with RWMA Bulletin 5 standards.

Weldsafe 5000 Operation

Ground Fault Sensing Operation

The Weldsafe 5000 protects operators and equipment from dangerous leakage currents that may occur when a

circuit is energized. The device has harmonic filtering to prevent nuisance tripping and a pick-up response time of

< 25mS.

• Ground Fault Protection

The Weldsafe 5000 ground fault function has two ground fault settings which will typically correspond to the size

of the manual transgun. Setting 1 is the factory setting. This setting should always be used whenever practicable.

Generally, Setting 1 will work for transguns smaller than 100 KVA. For manual guns larger than 100 KVA or with

very high amperages (>40,000A), Setting 2 can be selected. All settings meet or exceed current RWMA

recommendations. To determine which setting is correct, consult with your service operator.

• C.T. Loop Monitoring

The Weldsafe 5000 also continuously monitors the connection to the current transformer to ensure proper

functioning of the ground fault sensing. If this connection is broken, the unit will immediately operate.

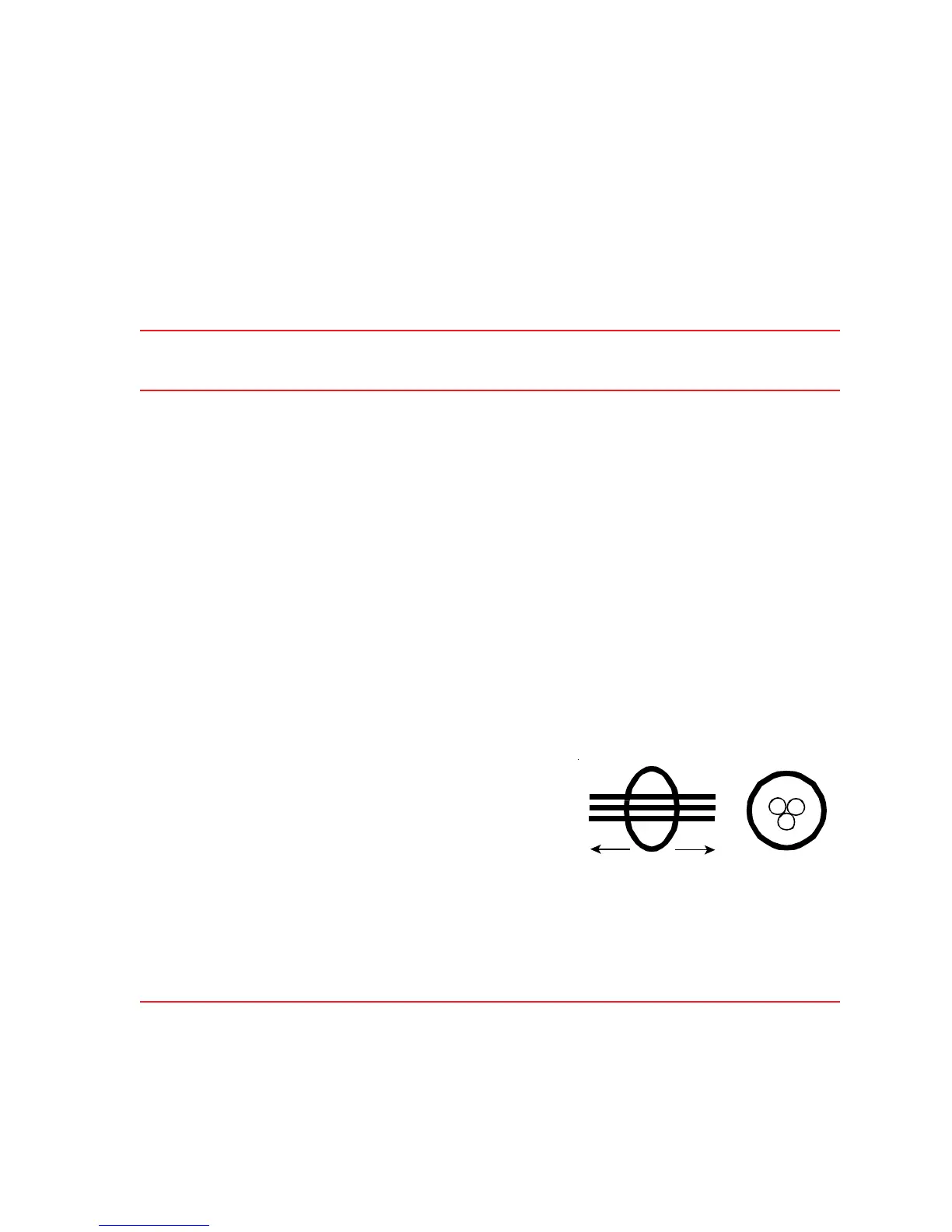

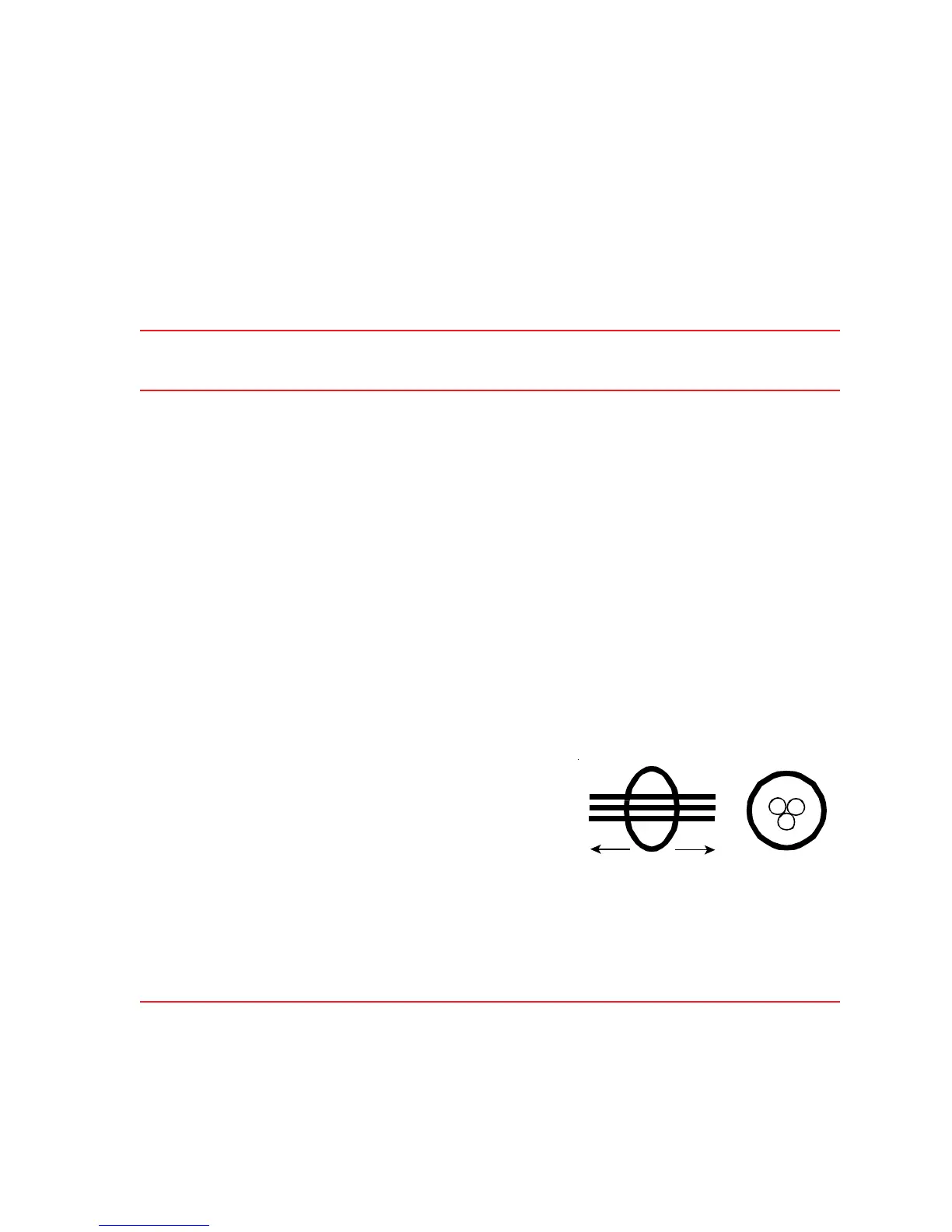

• CT600/.../WKE Series Current Transformers

The ground fault protection function of the Weldsafe 5000 operates together with a CT600 series current transformer.

There are different sizes available ranging from 1” to 5-1/8” depending upon the size of the load conductors

passing through window. The C.T. is connected across terminals 16

and 17. Only the load carrying conductors pass through the C.T. The

ground wire must remain outside the C.T. core. It is also important

that the cables passing through the C.T. be as straight as possible

(see diagram) to minimize the possibility of core saturation.

CT600/60/2 for High Current Applications

In applications where very high current is present, as in the case of a

very large hand-held welding gun (>100KVA, 40,000A), this high

current may influence the operation of the CT and cause nuisance tripping. The mounting and location of the CT

within the control panel is very important. In order to get optimum results from the CT, it is recommended that the

CT be mounted on the output side. This reduces the influence of any internal leakage caused by components in

the welding control. For systems above 100 KVA, it is advisable to use either coaxial cable or order the CT600/60/2.

This CT has been specifically designed with a 6" metal core insert and provides the same shielding from the high

current as the coaxial cable.

Ground Checking Operation

The Weldsafe 5000 has several protective methods to ensure proper grounding of fixed or portable equipment. If

the unit senses any one of the following conditions, it activates the alarm relay (K2).

• Pilot Wire Ground Integrity Check

The Weldsafe 5000 monitors the resistance of the return path to ground via a ground connection from terminal 30

and a standard loop pilot wire going to the equipment from terminal 27. The unit continuously sends a

2"2"

Weldsafe 5000 Data Sheet • Circuit Savers • phone: (972) 370-0664 • www.circuitsavers.com • March 10, 2006

Loading...

Loading...