R301.1 Experion C300 Controller User's Guide 3

11/06 Honeywell

C300 Controller Purpose

This section provides a quick comparison of C200 and C300 Controller features and

reference to topics in this book for a given task related to using the C300 Controller with

the Experion system. Click on the topic to view it.

Topic

C300 Controller and C200 Controller comparison

Getting started task list

C300 Controller and C200 Controller comparison

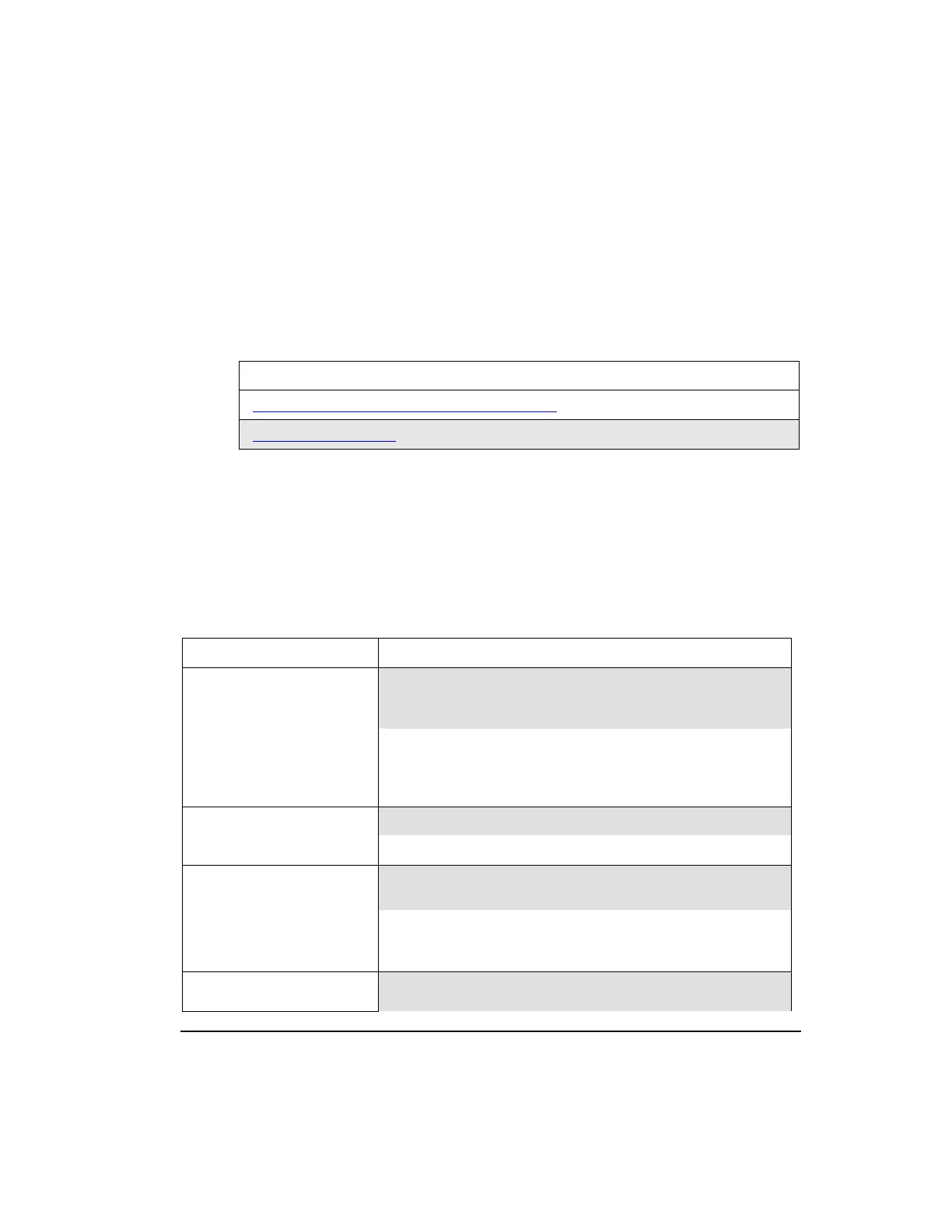

If you are familiar with the operation and capabilities of the C200 chassis-based process

controller, then you can readily appreciate the design improvements and greater

capabilities for process control that the C300 Controller provides. The following table is

a listing that compares design features and operational improvements of the C300

Controller with the C200 controller.

Controller Feature Comparison

C200 – Chassis-based controller with plug-in modules for

Control Processor, I/O Link Interface, Redundancy, FTE

interface, Fieldbus, other I/O and control modules.

Form Factor

C300 – A single control module that plugs into an Input Output

Terminal Assembly (IOTA). Control module functions include

a Control processor, two I/O Link interfaces, Redundancy

functions, and FTE interfaces.

C200 – 4MB User Memory

Memory (RAM)

C300 – 16MB User Memory

C200 –Two identically-equipped controller chassis that contain

two Redundancy Modules (RM) provide controller redundancy.

Redundancy

C300 – Controller redundancy function is built in. A second

C300 Controller and redundancy cable is all that is required for

redundant controller operation. (No RMs)

I/O Link Interface C200 – An I/O Link Interface plug-in Module (IOLINK) installed

in the controller chassis is required to connect PMIO I/O to the

Loading...

Loading...