5 Installation and commissioning

HSD S.p.A. © - h0104k01a.fm120718

105

Any drainage pipes must be orientated

downwards. The pipes must remain

downward-facing even when the machine

moves the electrospindle.

During normal use of the fluid distributor, the following precautions should always be

adopted when the electrospindle is not rotating.

• Introduction of pressurised air (4 ÷ 6 bar) before inserting the coolant.

• Every time the flow of coolant ends, use a jet of pressurised air to discharge the

circuit and thereby prevent any residual liquid from seeping out of the drainage

points unexpectedly.

For further information please refer to the documentation supplied by the rotating joint

manufacturer.

5.7.1 Rotary fluid distributor fitted by the user

Refer to the specific dimensional drawings of your own electrospindle, and the documentation

supplied by the fluid distributor manufacturer.

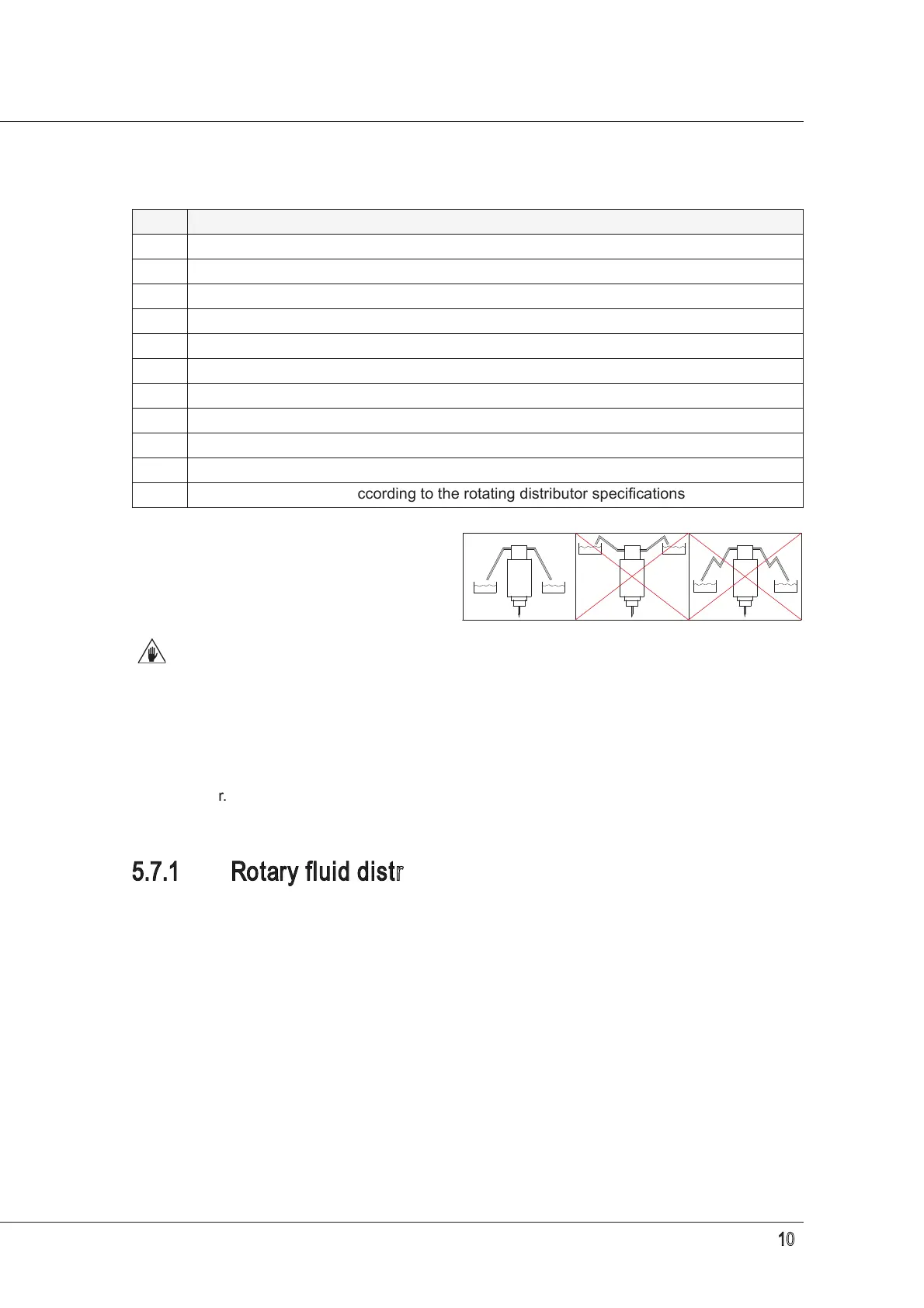

Ref. Description

A Cone cleaning air branch

B Branch for tool coolant fluid

C To connect to the fluid distributor

1 Pneumatic circuit supply

2 Pre-filter 5 µm see paragraph 5.5.1

3 Oil separator filter 0.1 µm see paragraph 5.5.1

4 Pressure regulator with pressure switch 4 bar (58 PSI)

5 Monostable 3-2 valve with electro-pneumatic control and spring return

6 One-way spring valves

7 Air, water or other fluid supply, according to the rotating distributor specifications

8 Filters and regulators, according to the rotating distributor specifications

Loading...

Loading...