7 Operation and regulation

HSD S.p.A. © - h0106k01a.fm120718

131

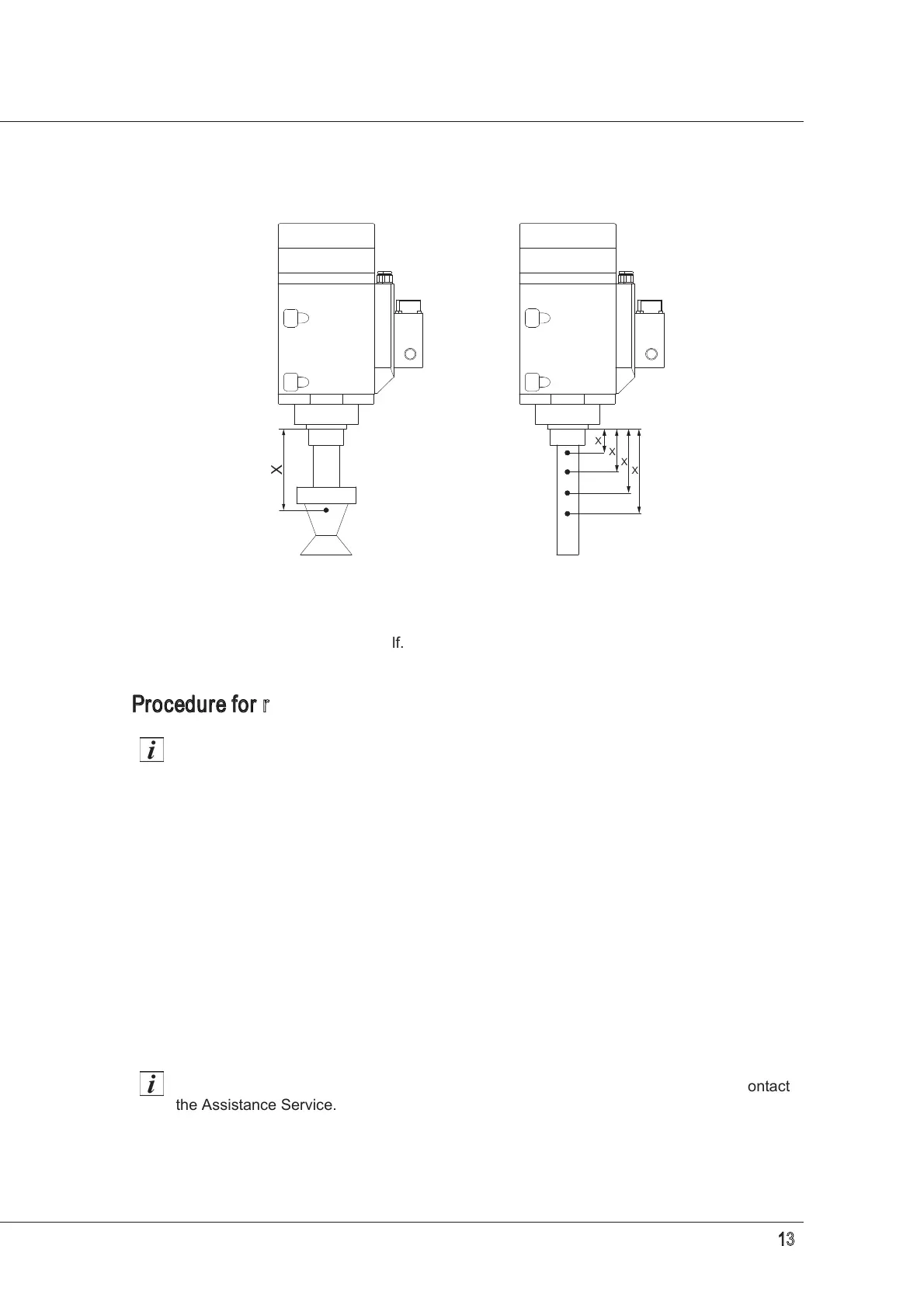

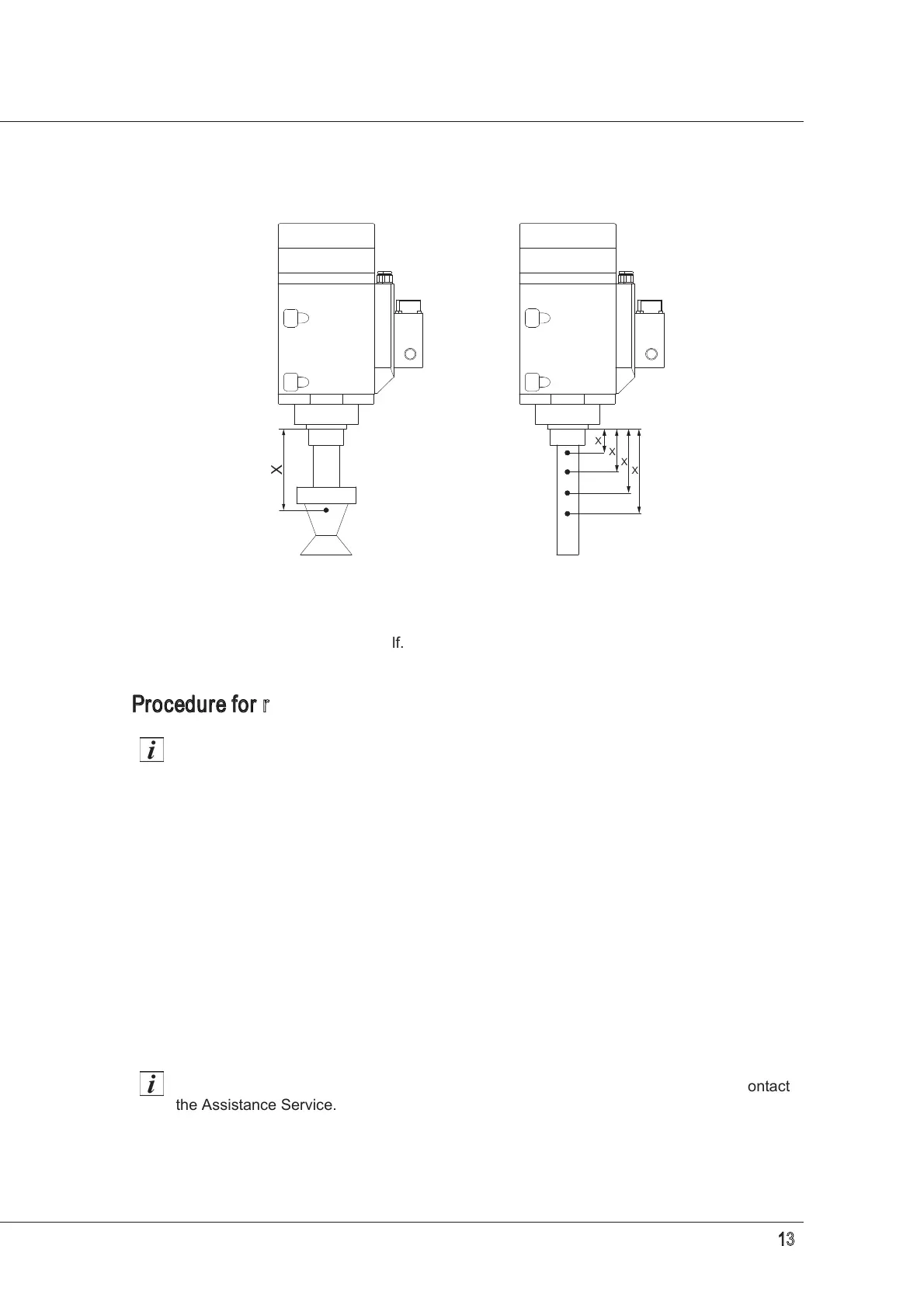

5. Use the value X to choose the right curve on the graph.

All tools, whatever their shape, can be considered as equivalent to a cylindrical tool (as shown

alongside the graphs on the following pages). From the graphs, select the curve corresponding to

the position of the centre of gravity of the tool in question, then read the maximum number of rpm

according to the weight of the tool itself.

Procedure for reading the graphs

The graphs on the following pages are merely an example, in that they don't take into

account the machining parameters, the specific characteristics of the tool used by the

customer, or the type of material being machined (because the manufacturer cannot be

aware of these factors).

It is the user's responsibility to assess the maximum speed for the safe use of the

tool in each individual situation.

1. Identify the graph relating to the electrospindle in use.

2. Select one of the curves according to the distance "X" between the spindle nose and centre of

gravity "G" of the tool+tool holder assembly. If the value "X" measured on the electrospindle in

use does not appear on the graph, select the curve associated to the next highest "X" (see

example)

3. Read the maximum speed value corresponding to the weight of the tool+tool holder assembly.

4. If the weight or the distance of G is higher than that provided for by the manufacturer, it is the

user's responsibility to evaluate the maximum safe operating speed case by case.

If it is thought that the tool may be too large and could damage the electrospindle, contact

the Assistance Service.

Loading...

Loading...