7 Operation and regulation

138

HSD S.p.A. © - h0106k01a.fm120718

Sensor S1+S4: “HSK cone locked in the correct position” signal

Sensor S4 is only present in HSK versions. Sensor S1 and S4 are connected in series. Sensor S1

checks the presence of the HSK tool holder cone in the closed collet, and if positive enables the

reading of sensor S4, which checks it is correctly positioned. When enabled by S1, S4 checks that

the surface stops of the tool holder cone and the HSK coupling system are in correct contact. The

output only changes to “ON” if both conditions are verified as positive.

Ignore the output of S1+S4 during the period from the tool release command to the tool

coupling command.

Sensor S2: “collet open” signal

Signal S2 is used during the tool change cycle: it detects the opening of the collet and whether it is

possible to continue with the next phases of the tool-change cycle.

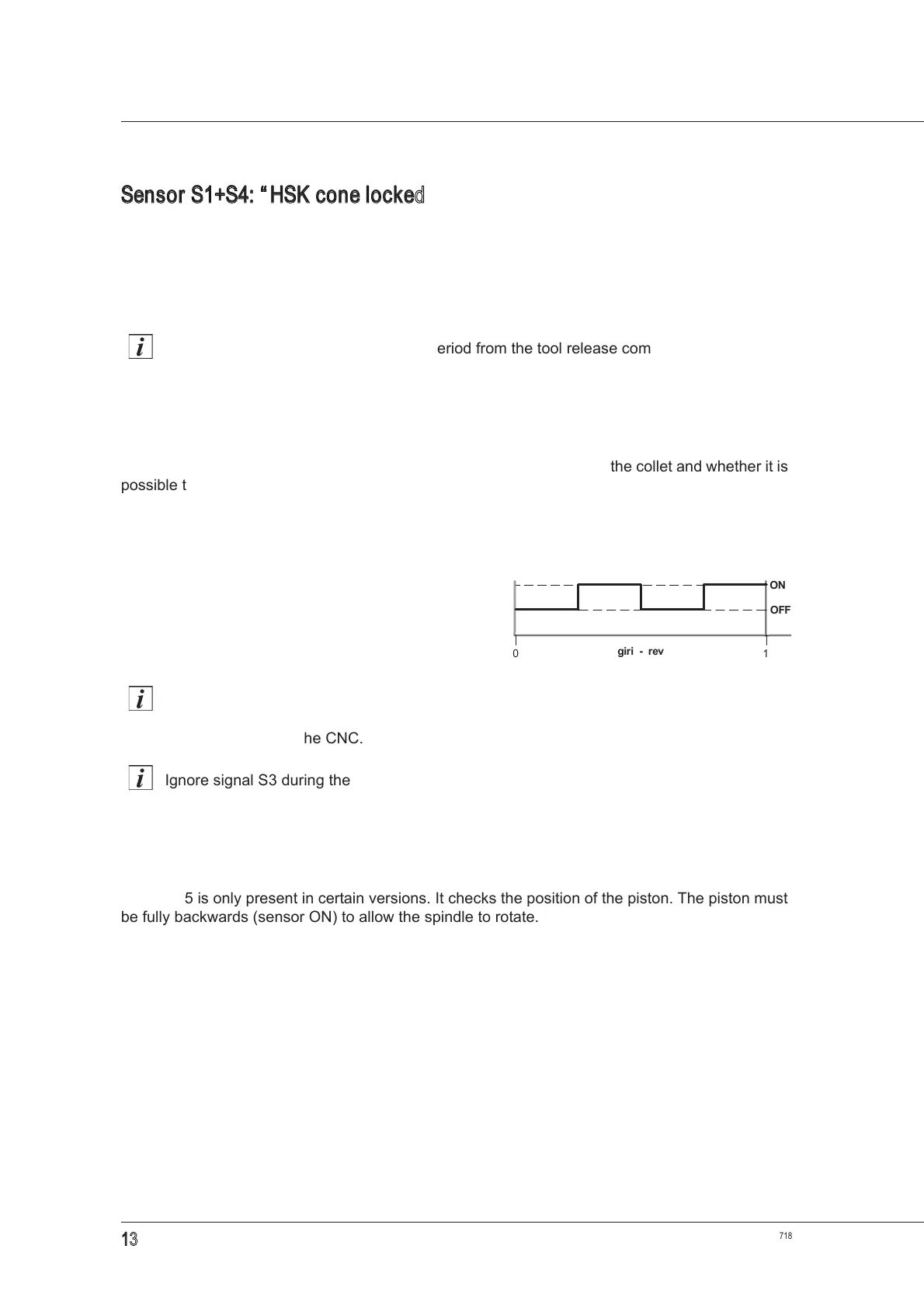

Sensor S3: spindle shaft rotation speed

Sensor S3 is only present in certain versions. It

provides two “ON” pulses and two “OFF” pulses

with each rotation of the shaft, as shown in the

figure.

Beyond a given rotation speed, output S3 may appear permanently "ON" and then return to

normal when the speed falls below this threshold. This is not a malfunction but depends on

the performance of the CNC.

Ignore signal S3 during the tool-change phase, as it may randomly display either one or

other of the two states (“ON” or “OFF”).

Sensor S5: “piston backward” signal

Sensor S5 is only present in certain versions. It checks the position of the piston. The piston must

be fully backwards (sensor ON) to allow the spindle to rotate.

Loading...

Loading...