7 Operation and regulation

126

HSD S.p.A. © - h0106k01a.fm120718

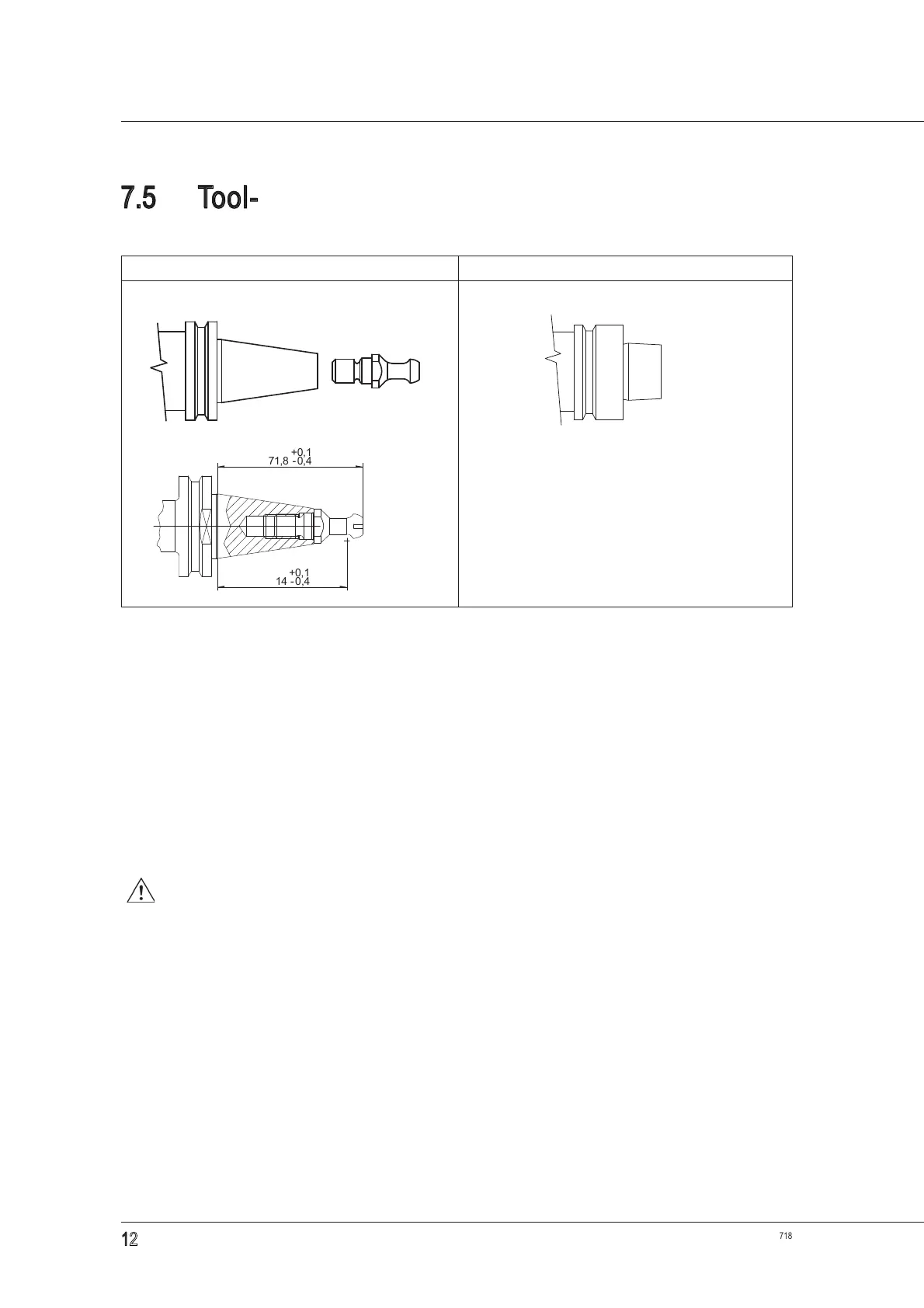

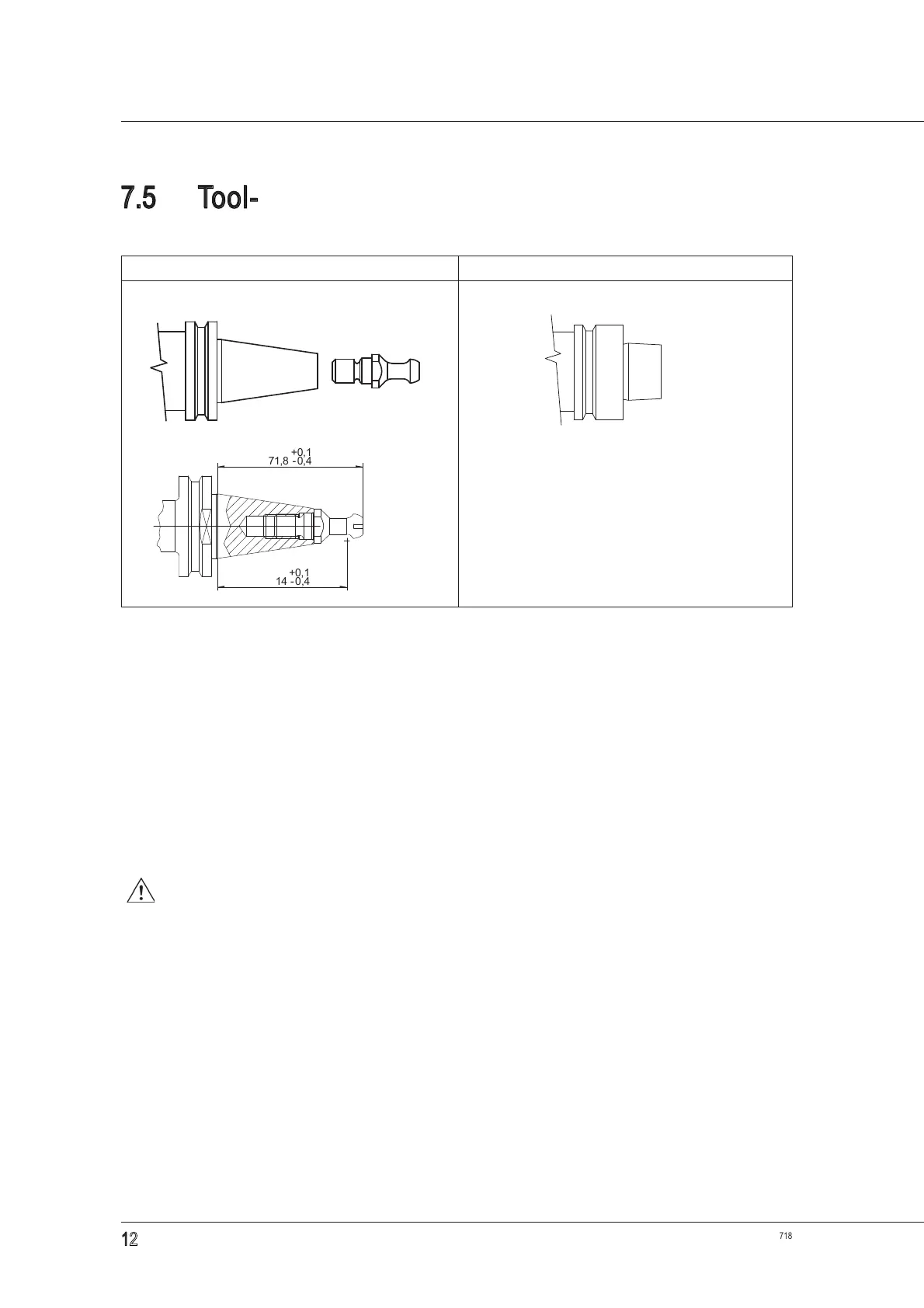

7.5 Tool-holder cone

The geometry of the taper must comply with standard DIN69871 for ISO30 cones, and

standard DIN69893 for HSK cones.

The ISO30 tool holder cone must have an AT3 degree of accuracy.

Avoid the presence of inserts, slots or other forms that could disturb the dynamic balance of

the tool holder.

At the maximum rated speed of the electrospindle, the dynamic balance quality grade must be

G = 2.5 or better (standard ISO1940).

The balancing is carried out with the tool holder assembled (cone, spring collet, ring nut, tool).

The screw dowel (also called the tang) of the ISO30 cone must be exclusively that supplied by

HSD (part number 0804H0009).

It is forbidden to use tool holders that do not comply with the above conditions. Non

compliance with these instructions can lead to a risk of breakage or an imperfect

coupling of the tool holder cone, with the resulting risks for the user.

CONE ISO DIN 69871 HSK DIN 69893 CONE

Figure 3 Figure 4

64,014

+0,1

-0,4

71,8

+0,1

-0,4

Loading...

Loading...