9 Replacing components

184

HSD S.p.A. © - h0108k01a.fm120718

Pay attention to the dosage of the thread-locker liquid. Excessive quantities may

unintentionally obstruct holes and/or adversely affect the operation.

Always use an adequate quantity of thread locking compound and also pressurised

air to make sure that the excess material has been removed.

Calibrate the sensors - see paragraph 9.3 “Replacing and adjusting the sensors”.

Even if only one segment (petal) breaks, the entire collet must be replaced. All

segments of the collet must have the same identification number.

Consult appendix

B “Spare parts” for information regarding the codes of the HSK collets and HSK

collet assembly tools.

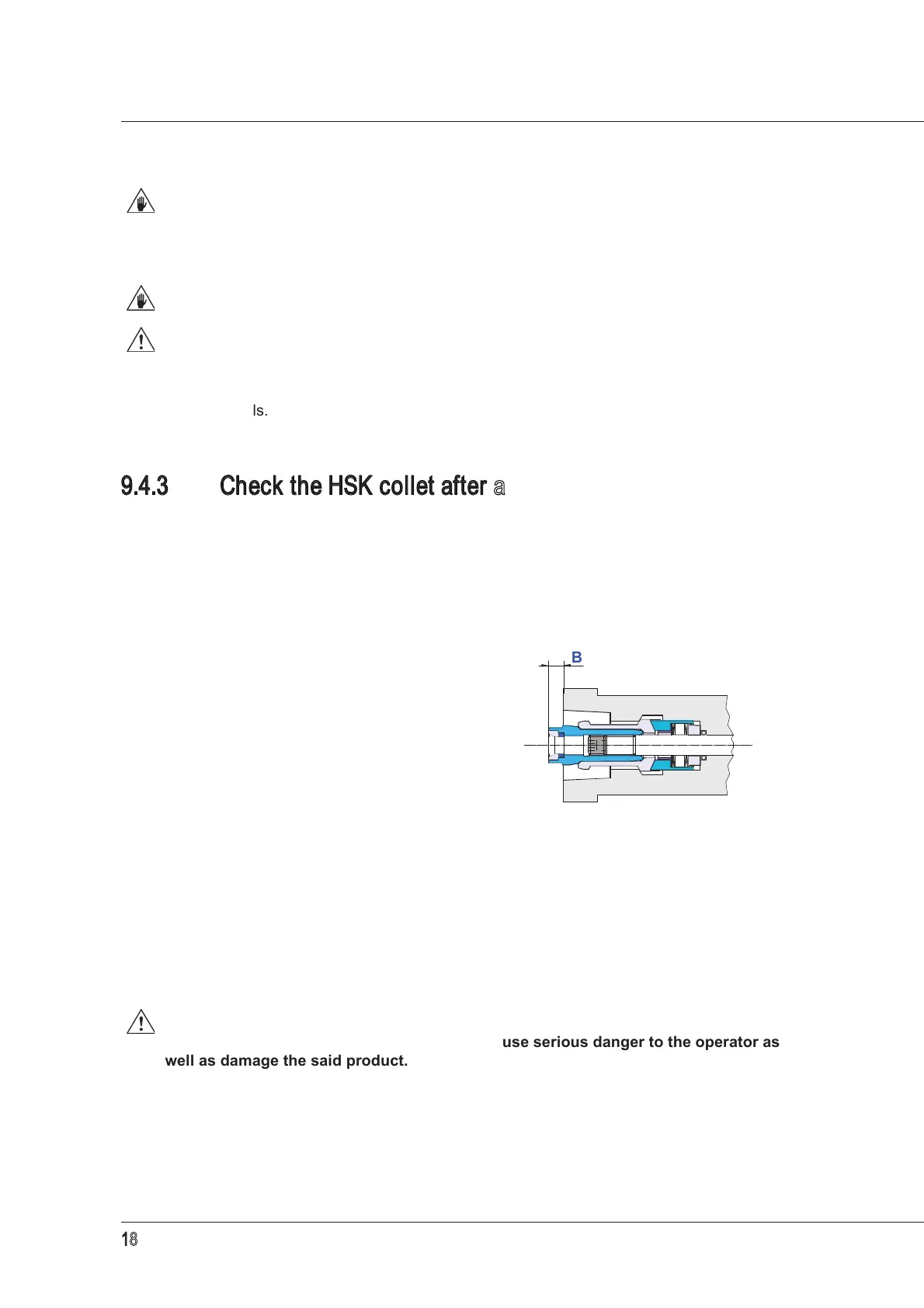

9.4.3 Check the HSK collet after approximately 100 locking

operations

After replacing the HSK collet, it is advisable to check its operation after approximately 100 locking

operations.

Bring the spindle to the

“Collet open (tool-holder cone ejected)” condition (see page 140), then

continue with the procedure.

Check the ejection position (see position

“B” in table 1 on page 125);

if the position is correct, move on to

check the next point;

otherwise, if the position is not correct,

loosen the lock screw in the screw dowel

and carry out the entire procedure from

point

7 in paragraph 9.4.2 “Assembling

the HSK collet in the spindle”

.

Check the axial force exerted by the locking device on the tool holder (the use of the Power

check is recommended). If the force measured is less than 70% of the minimum value

indicated in paragraph

7.4 “Tool-holder locking and ejection device”, proceed as follows:

• Grease the collet again as indicated in paragraph

8.1.7 “Lubricate the HSK collet”, and

check the axial force on the tool-holder again.

• if the force is still less than 70%, change the collet and check again;

• if the force is still less than 70%, change the clamping device completely.

Check operation of the collet, as indicated.

Failure to check operation of the collet can cause serious danger to the operator as

well as damage the said product.

B

Loading...

Loading...