8 Maintenance

HSD S.p.A. © - h0107k01a.fm120718

153

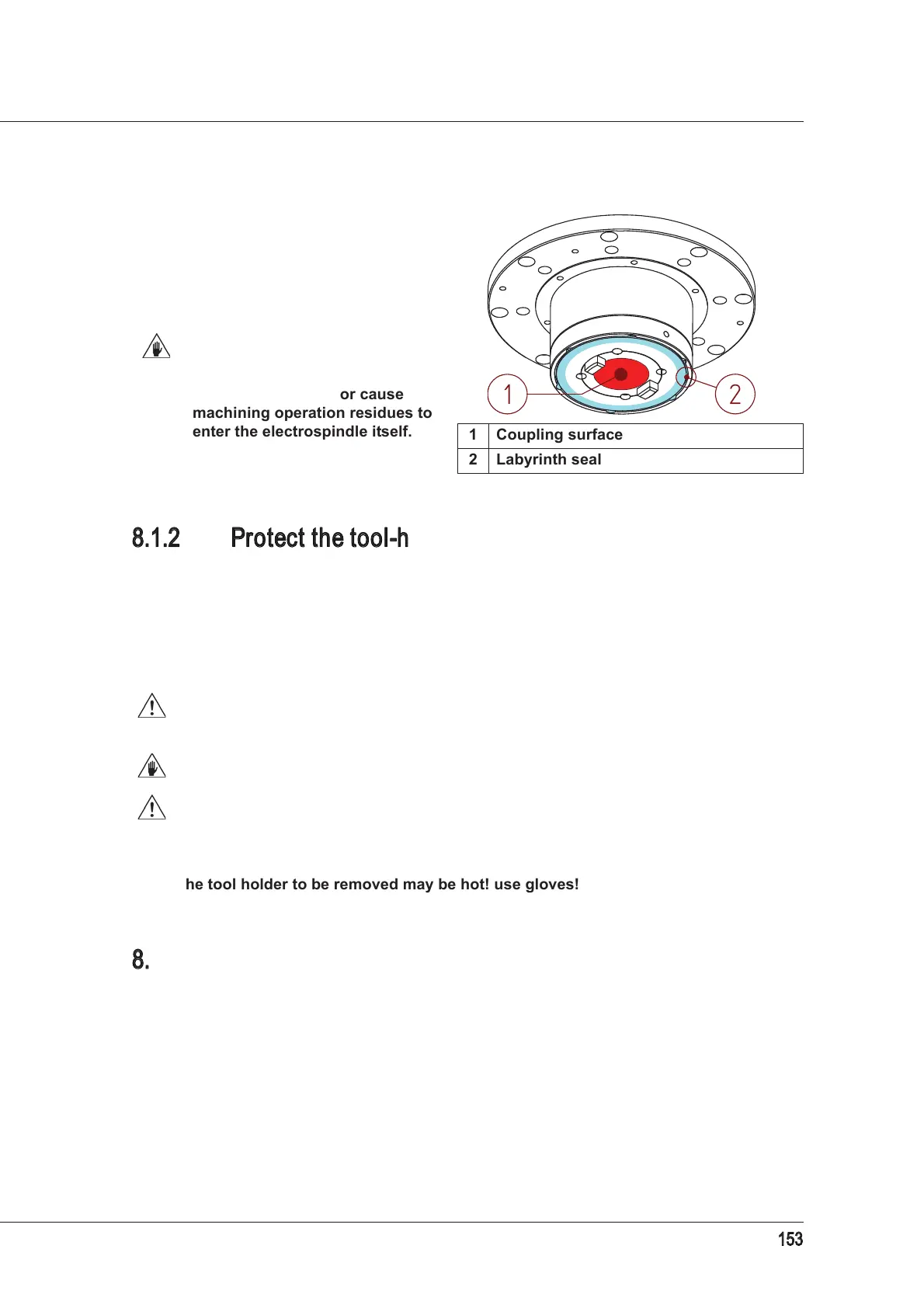

8.1.2 Protect the tool-holder seat

Frequency: DAILY

The tool holder seat must always be protected from the intrusion of impurities, which could soil,

oxidise, or in any way degrade the contact surfaces: never leave the electrospindle without a tool

holder cone inserted.

The tool-holder cone seat in the spindle shaft must always be protected against

impurities: fit a suitable plug or a tool-holder cone.

The cone used for protection must not have through holes.

To avoid sticking, remove the tool holder in the electrospindle both after any heavy

work as well as at the end of the working day, and replace it with a clean tool holder at

room temperature to protect the interior of the electrospindle from the external

environment.

The tool holder to be removed may be hot! use gloves!

8.1.3 Drain the pneumatic circuit filters

Frequency: DAILY

At the end of each work shift, discharge the compressed air circuit to allow the automatic filter

cleaning system that protects the HSD product to function.

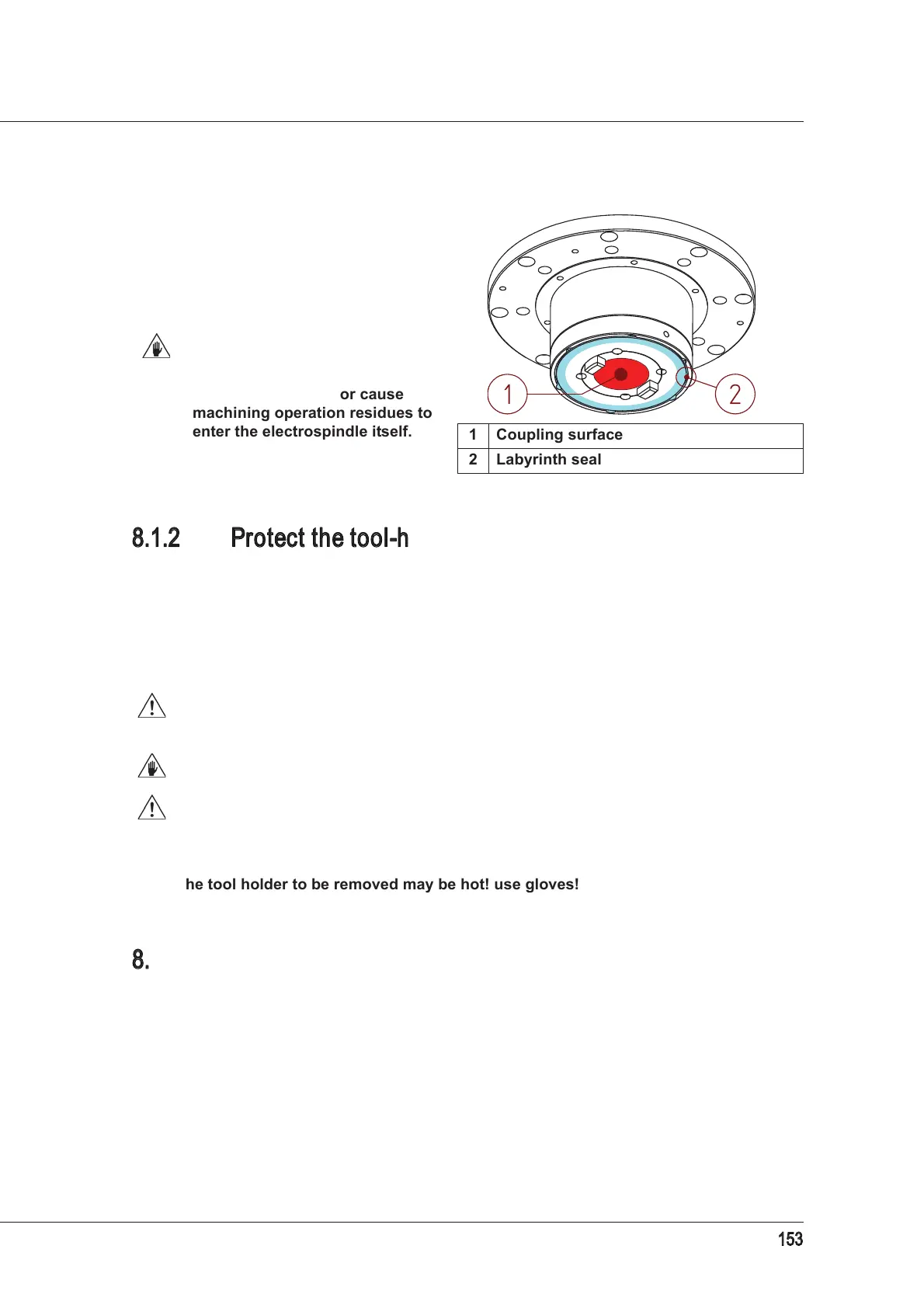

Never direct a jet of compressed

air in the zone of the pressurised

labyrinth seal, in that any

infiltration would damage the

interior of the electrospindle.

Do not direct a jet of compressed

air inside the electrospindle when

the tool holder is not coupled, as

this could dirt the mating surface

with the tool holder or cause

machining operation residues to

enter the electrospindle itself.

1 Coupling surface

2 Labyrinth seal

Loading...

Loading...