9 Replacing components

178

HSD S.p.A. © - h0108k01a.fm120718

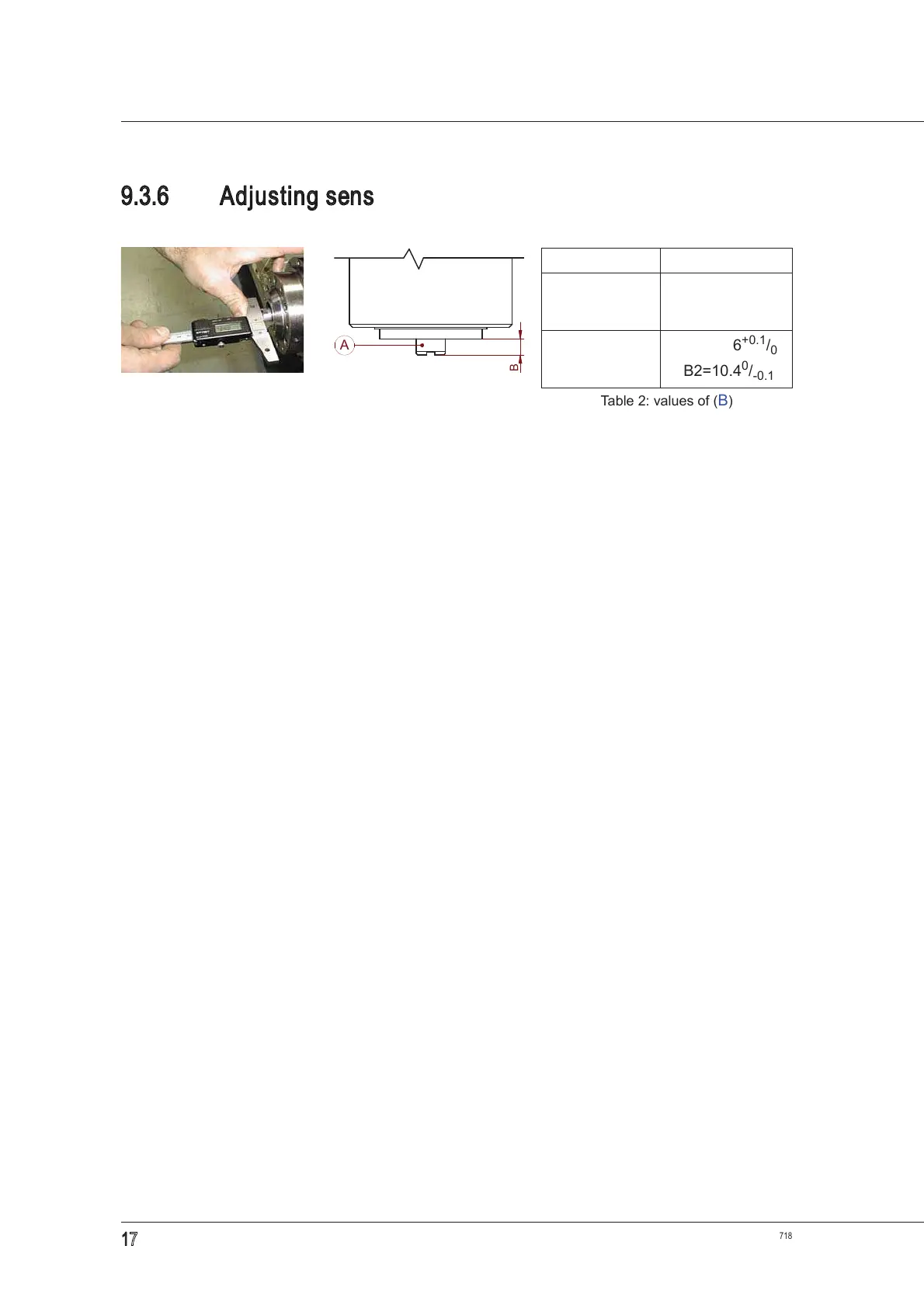

9.3.6 Adjusting sensor S2 for HSK versions

After replacing the sensor as described in paragraph 9.3.2 “Replacing the sensor unit”, calibrate it

as follows:

1. bring the spindle to the

“Collet open (tool-holder cone ejected)” condition, where the piston is

forward and the position (B) (figure

20) assumes the maximum value;

2. as shown in figures 19 and 20, use a depth gauge to check that position (B) of the ejector in

relation to the spindle nose assumes the value B1 indicated in table

2;

if this is not the case, make the adjustment described in paragraph

7.4.1 “Checking and

adjusting the HSK collet ejection position”

before adjusting the sensor;

3. bring the piston backward so the position (B) assumes the minimum value;

4. feed the cylinder by means of a unidirectional pressure regulator, set initially at 0 bar (0 PSI);

5. increase the pressure with 0.1 bar steps (1.5 PSI), in order to make the ejector move slowly;

6. stop when the position (B) reaches value B2;

7. rotate sensor S2 until you find the position that provides the

“ON” signal with (

B) > B2 and the

“OFF” signal with (

B) < B2;

8. tighten the screw that fastens the sensor completely;

9. perform a cycle of 10 tool changes;

10. at the end of the cycle, check that point [7] is met

without needing to move the sensor

;

11. if necessary, move the sensor and then repeat the entire procedure from the beginning;

12. if not necessary move the sensor, then make the machine perform a cycle of 100 tool

changes, using the largest possible number of different tool holders;

13. at the end of the cycle, check that point [7] is met

without needing to move the sensor

;

14. if necessary move the sensor, then repeat the entire process from the beginning;

15.

if it is not necessary

to move the sensor,

then

the S2 adjustment process is complete.

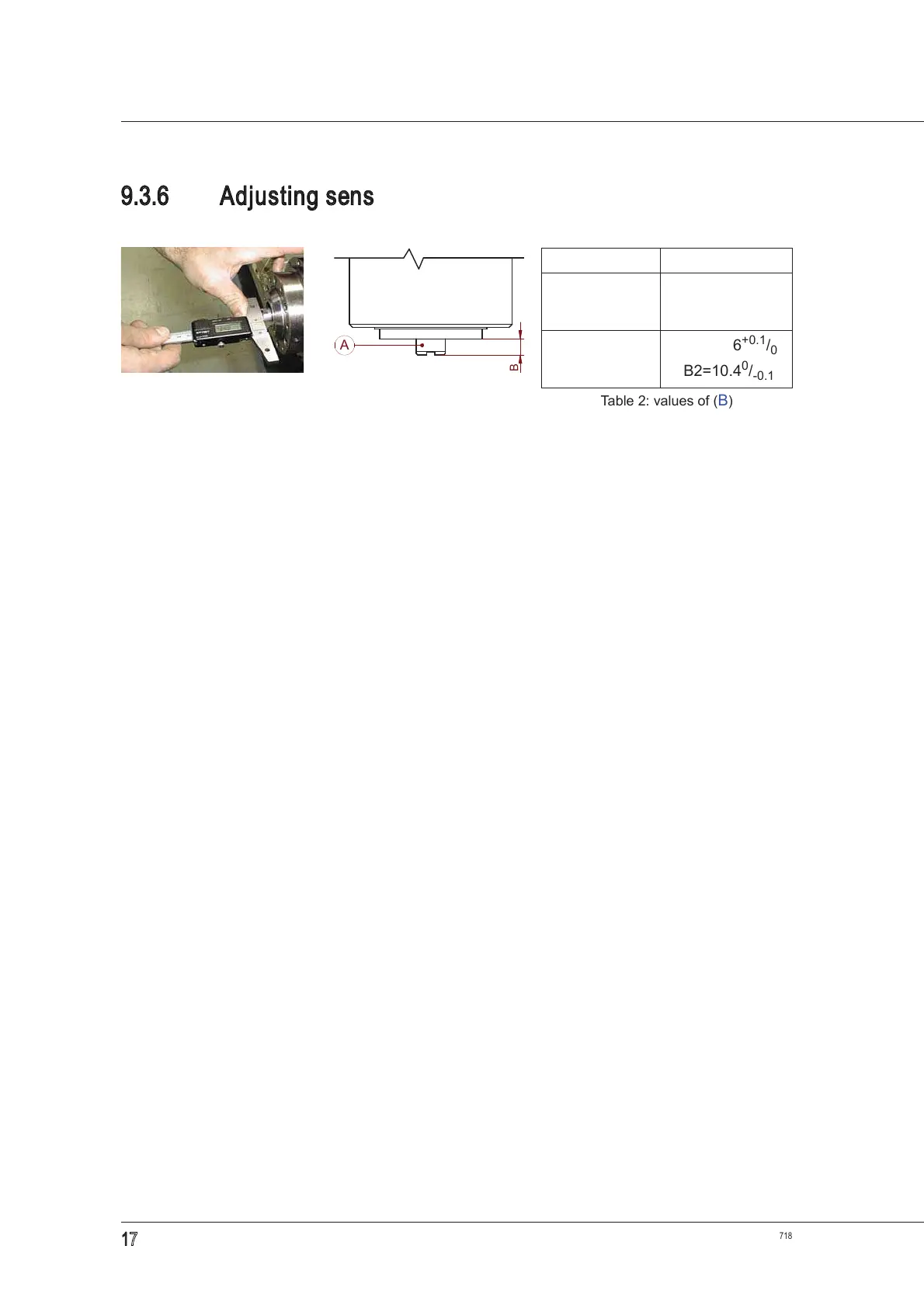

Figure 19: ejector position Figure 20: (A) ejector

(B) reference position

HSK form

B

(mm)

A40, E40, F50

B1=8.6

+0.1

/

0

B2=8.4

0

/

-0.1

A63, E63, F63

B1=10.6

+0.1

/

0

B2=10.4

0

/

-0.1

Table 2: values of (B)

Loading...

Loading...