9 Replacing components

HSD S.p.A. © - h0108k01a.fm120718

183

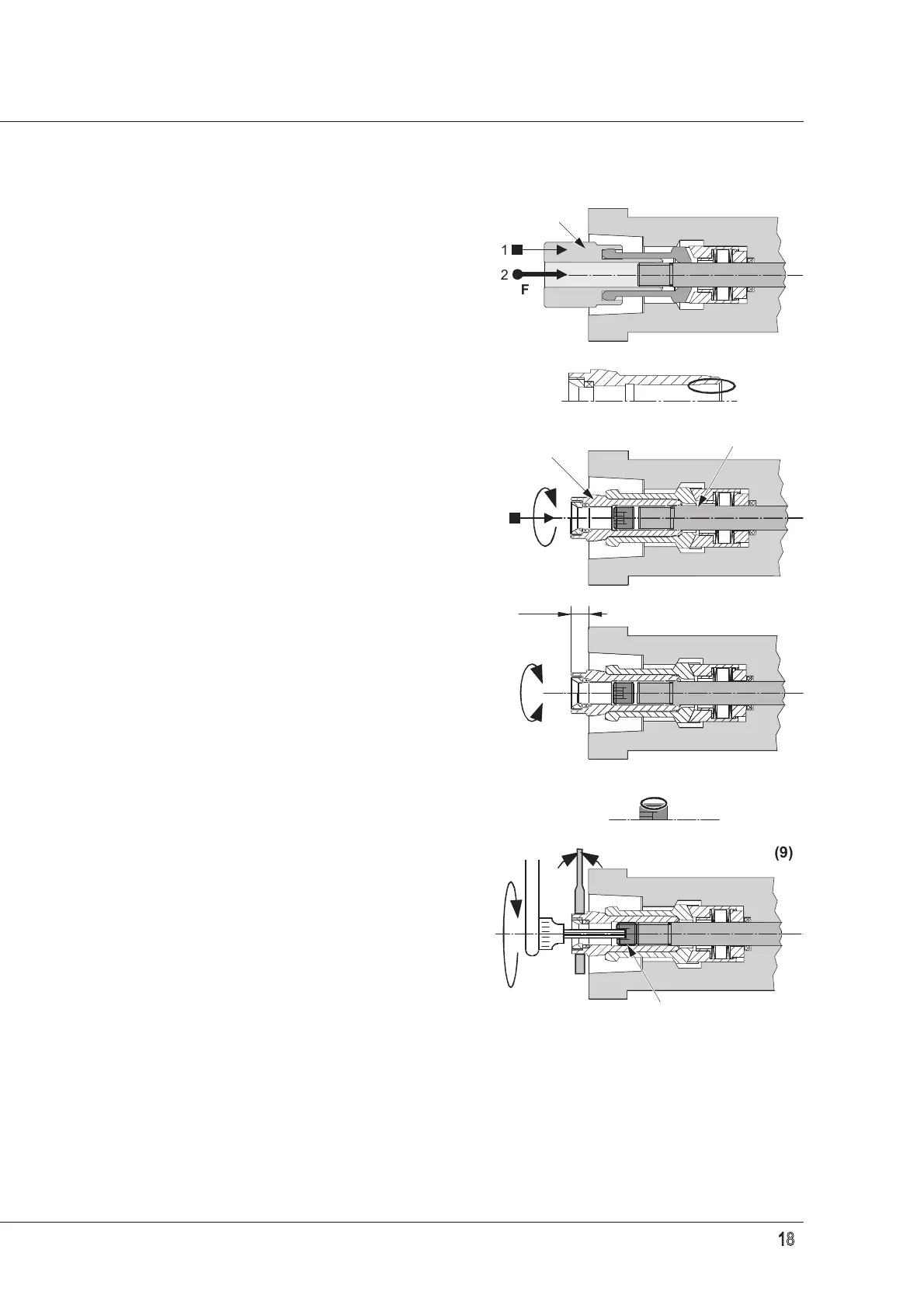

4b. As an alternative, using the

assembly tool (b):

Insert the collet segments in the

assembly tool. Insert the unit in the

spindle and apply the necessary force to

bring it to its position.

5. Lubricate the collet unit with assembly

grease.

6. The collet unit together with the pre-

mounted gaskets must be screwed onto

the screw dowel until reaching the set

screw position.

7. Bring the collet core to the adjustment

position

“B”(see paragraph

7.4.1 “Checking and adjusting the HSK

collet ejection position”

).

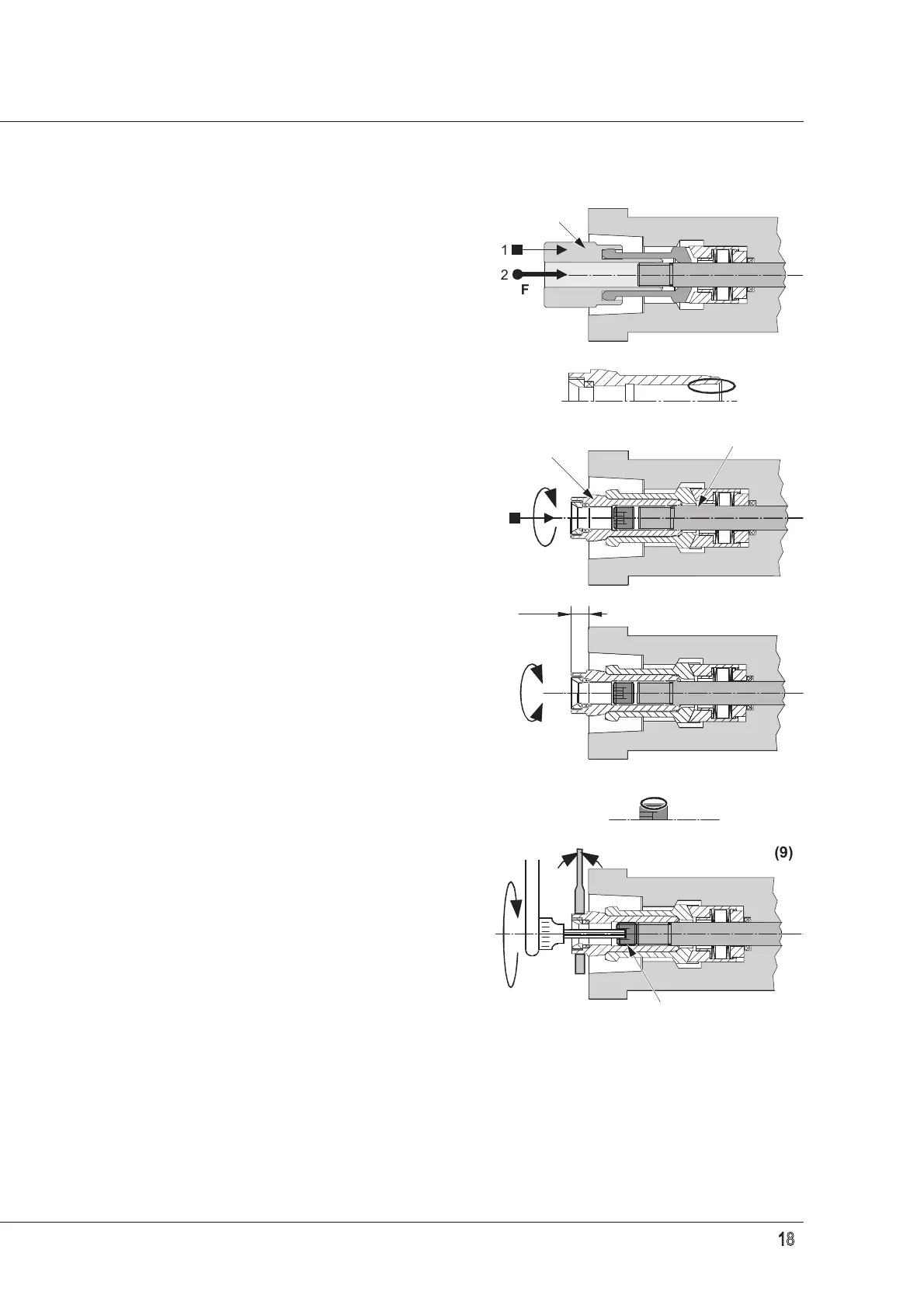

8. Spread medium-strength thread locking

compound LOCTITE 243 (or other

equivalent product) on the thread of the

lockscrew.

9. Tighten the lockscrew against the screw

dowel.

Observe the tightening values indicated

in table

3, paragraph 9.4.4 “Tightening

the lockscrew for the HSK collet”

.

Leave the thread locking compound to

rest so it can set (according to the

instructions of the manufacturer).

10. Check the axial force exerted by the locking device on the tool holder (the use of the Power

check is recommended). If the force measured is less than 70% of the minimum value

indicated in paragraph

7.4 “Tool-holder locking and ejection device”, proceed as follows:

• Grease the collet again, as indicated in paragraph

8.1.7 “Lubricate the HSK collet”, and

check the axial force on the tool-holder again.

• if the force is still less than 70%, change the collet and check again;

• if the force is still less than 70%, change the clamping device completely.

Loading...

Loading...