Kinco FD5P AC series servo driver

册

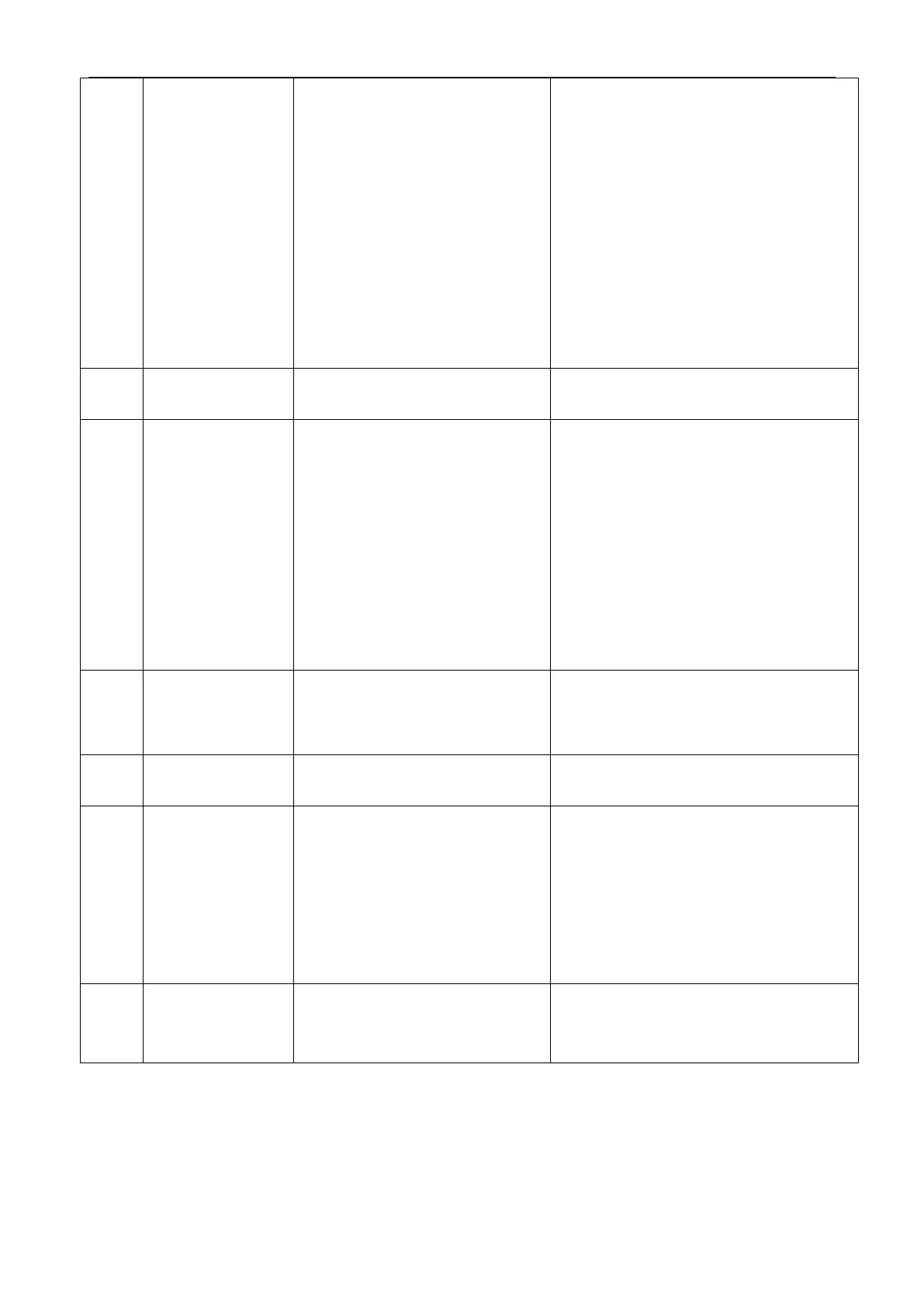

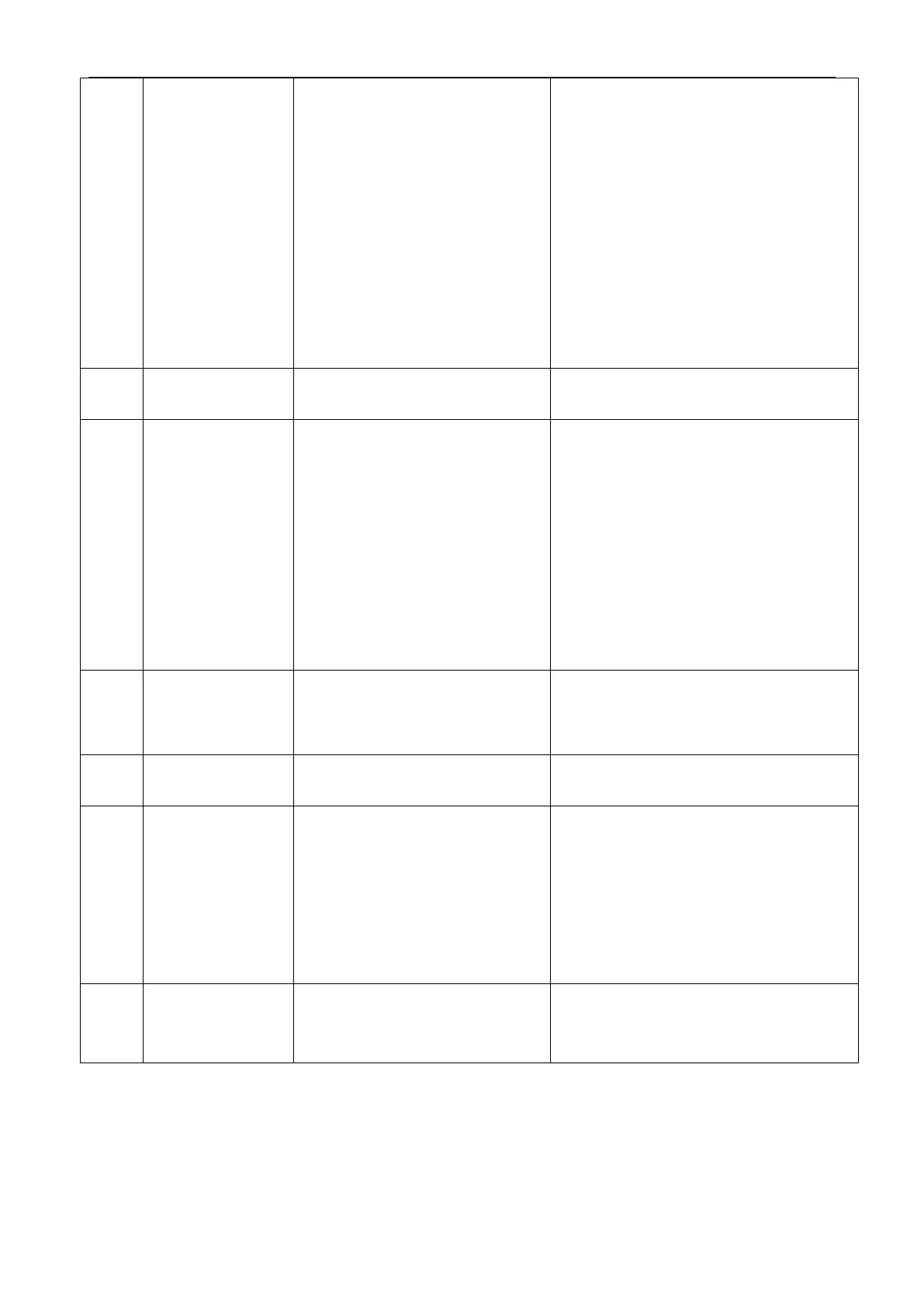

Chapter 8 Alarm Investigation

The actual following error exceeds the

setting value of Max_Following_Error.

1. Stiffness of control loop is too small.

2.The controller and motor together

can’t match the requirement of the

application.

3. Max_Following_Error (d2.25) is too small.

4. feedforward settings are not feasible.

5. Wrong motor wiring.

Step 1: Make sure the power cable UVW is connected

correctly

Step 2: Readjust the gain and increase the rigidity.

Refer to Chapter 7 for the rigidity adjustment method

Step 3: Readjust the maximum follow error

(0x606500)

Step 4: Readjust the maximum speed limit (0x607f00)

Step 5: Readjust the target current limit (0x607300),

the default value of the target current limit is equal to

the maximum motor current (0x64100B)

Step 6: Measure whether the lock line connection is

normal, measure the lock voltage, replace the motor

and compare the test

Step 7: Remove mechanical jams and apply lubricant

Logic power voltage is too low.

Check to see if logic power voltage is unstable.

The motor or drive is overloaded for a

long time, the possible reasons are:

1. Motor power line and encoder wiring

error

2. When the motor shaft is rotating, the

lock is not loosened

3. The drive control ring parameters are

incorrectly set

4. The mechanical device is stuck or the

friction is too large

5. Driver/motor selection error can not

meet the application requirements

Step 1: Check that the encoder/power line is

properly connected

Step 2: Measure whether the lock line connection

is normal, measure the lock voltage, replace the

motor and compare the test

Step 3: Adjust the parameters of the control ring

Step 4: Eliminate mechanical jams and apply

lubricant

Step 5: Run with reduced load or replace with

more powerful products

External input pulse frequency is too

high.

1, reduce the pulse frequency

2, when using more than 600KHz pulse, need to

increase the pulse frequency control

0x250808(panel address D3.38) value.

The motor temperature exceeds the

specified value.

Encoder cable error or not connected;

The presence of a 000.2 alarm indicates

that the communication encoder is not

responding

Step 1: Make sure that the encoder between the

driver and the motor is properly connected and the

cable is firmly connected.

Step 2: Check whether the current motor model

matches the motor code in the nameplate through

EA01 or the upper computer software. If the

current motor model is different from the actual

motor, please refer to Table 4-2 to self-identify the

motor parameters.

Data is damaged when the power is

turned on and data is read from the

EEPROM.

Step 1: Initialize the control ring parameters, save

the control parameters, and restart the drive. Step

Step 2: Import the cdi file through the host

software

Loading...

Loading...