Kinco FD5P AC series servo driver

册

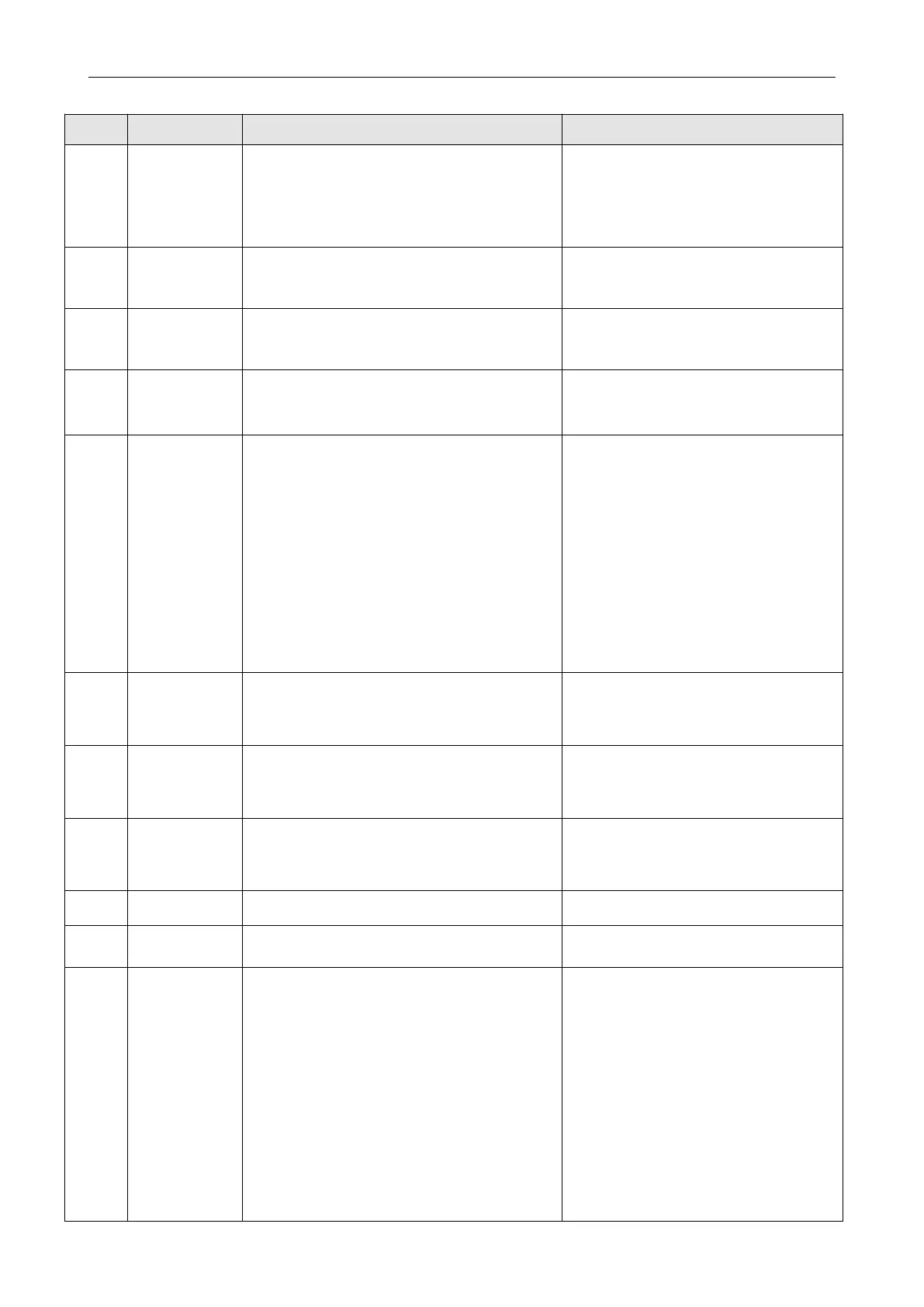

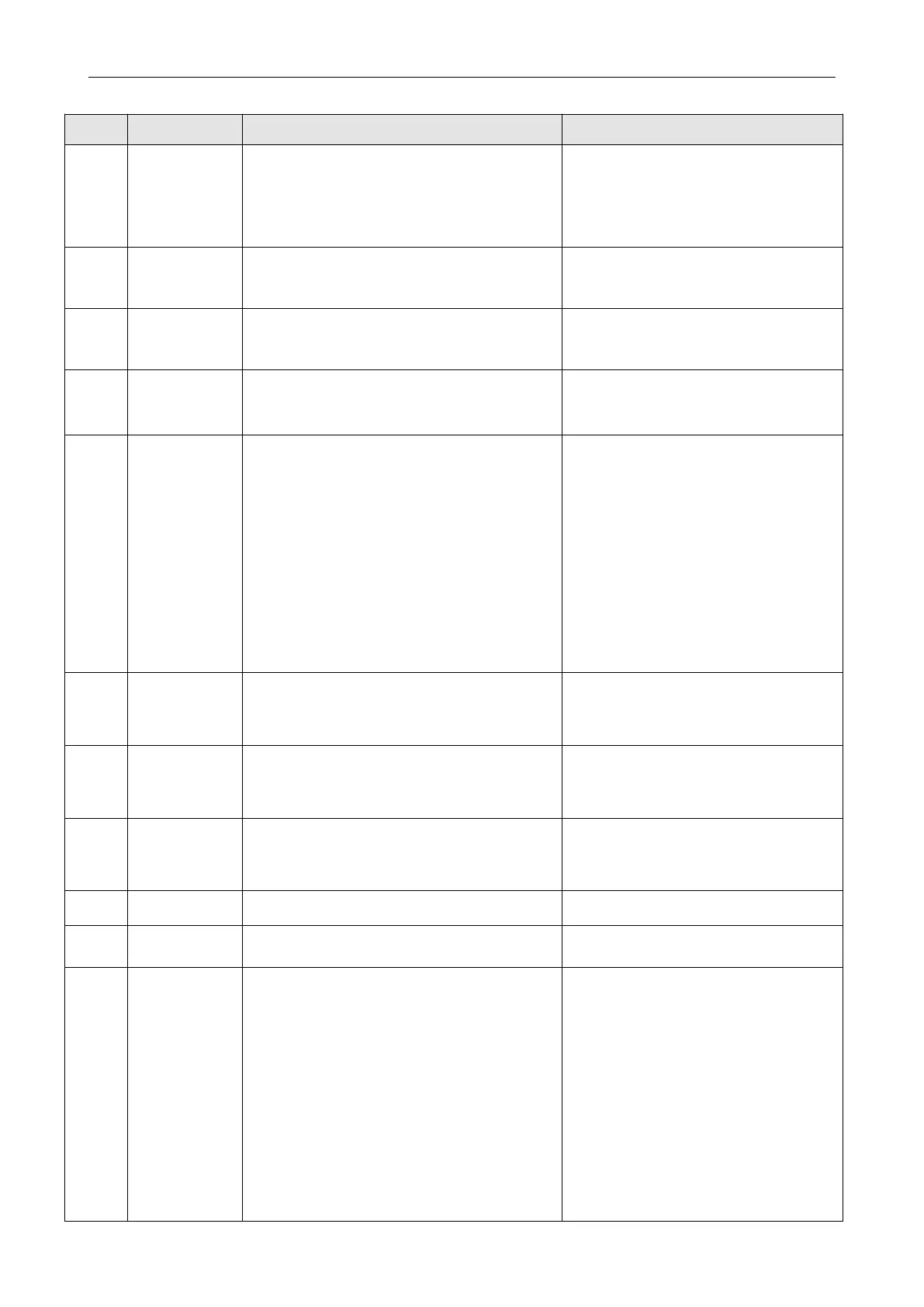

Chapter 8 Alarm Investigation

Table 8-2: Alarm codes of Error_State2 (extended)

Current sensor signal offset or ripple too big

Step 1: The current sensor generates an alarm

due to external interference. For details, see

3.2.2 Setting EMC Conditions.

Step 2: Current sensor circuit is damaged,

replace the driver and compare.

Software watchdog exception

After initializing the control ring parameters,

save the control parameters and restart the

drive.

Invalid interrupt exception

After initializing the control ring parameters,

save the control parameters and restart the

drive.

1. The software program does not match the hardware

2. An MCU error is detected

Step 1: Check the software version in the drive

properties and update the correct software

Step 2: Replace the drive and compare.

1. Motor model cannot be automatically identified

EEPROM No motor data or the motor is not configured

correctly

2. The motor line is missing, and a phase of the power

line UVW is not connected

Step 1: Connect the host computer software

to check whether the current motor model

matches the motor code on the nameplate;

Check that the current motor model matches

the motor code with panel address EA01. If

the current motor model is different from the

actual motor, please refer to Table 4-2 to self-

identify the motor parameters.

Step 2: Make sure the motor power line UVW

is connected correctly and reliably

Step 3: Replace the power cable or driver

comparison test.

DIN function “pre_enable” is configured, but the input is

inactive when the controller is enabled or should

become enabled

Positive position limit (after homing), position limit only

causes error when Limit_Function (2010.19) is set to 0.

Negative position limit (after homing), position

limit only causes error when Limit_Function

(2010.19) is set to 0.

Internal firmware error in SPI handling

Please contact the supplier.

This function is enabled only when the Communication

interruption mode (0x600700) is set to 1

In full closed loop mode, the counting direction of the

main encoder is opposite to that of the motor encoder

Step 1: Check the count direction of the main

encoder and the count direction of the motor

encoder, the count direction is inconsistent,

please change the count direction of the main

encoder (0x250A03)

Step 2: The master encoder speed is not

proportional to the motor encoder speed. Check

the mechanical installation, exclude mechanical

slippage or jammed, check the full closed spindle

check (0x250A05) and full closed slave shaft

check (0x250A06) and full closed loop ratio

check (0x250A09) Settings.

Loading...

Loading...