4. Parameters

4-57

(1) Inertia Ratio Setting [P1-00]

An inertia ratio shall be set by calculating load inertia from the machine system and rotor

inertia from the motor specification table.

Setting inertia ratio against load is an important control parameter for the operation of the

servo. Setting accurate inertia ratio is crucial for optimal servo operation.

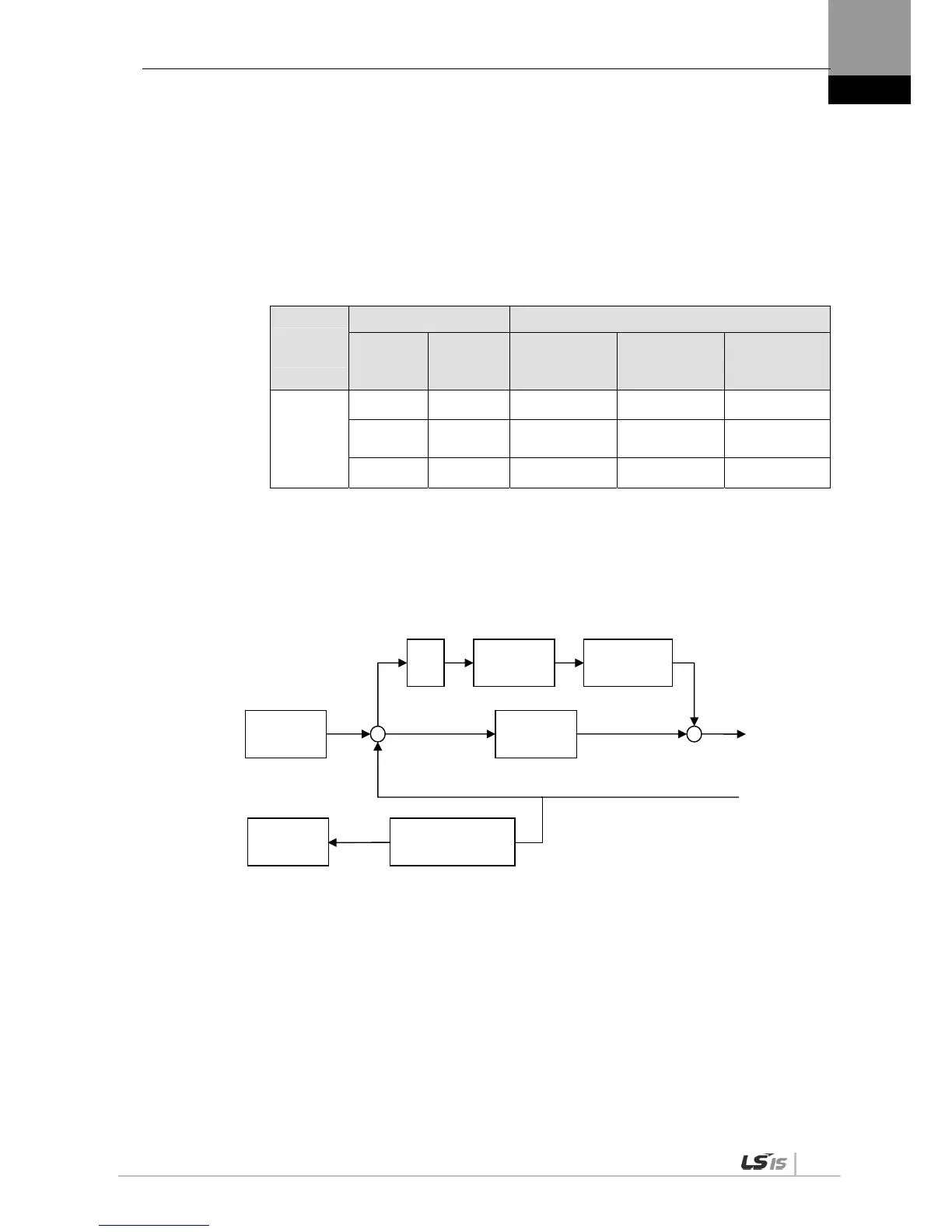

The following table contains control gain recommendations for different categories of inertia

ratio:

Motor

Flange

Inertia Ratio Gain Range

Category

[Inertia]

(Multiple)

Position

Proportional

Gain

Speed

Proportional

Gain

Speed Integral

Gain

40

~ 80

Low inertia 1 ~ 5 40 ~ 90 400 ~ 1000 10 ~ 40

Medium

inertia

5 ~ 20 20 ~ 70 200 ~ 500 20 ~ 60

High inertia 20 ~ 50 10 ~ 40 100 ~ 300 50 ~ 100

* Inertia ratio can be tuned during a test drive if it is hard to calculate.

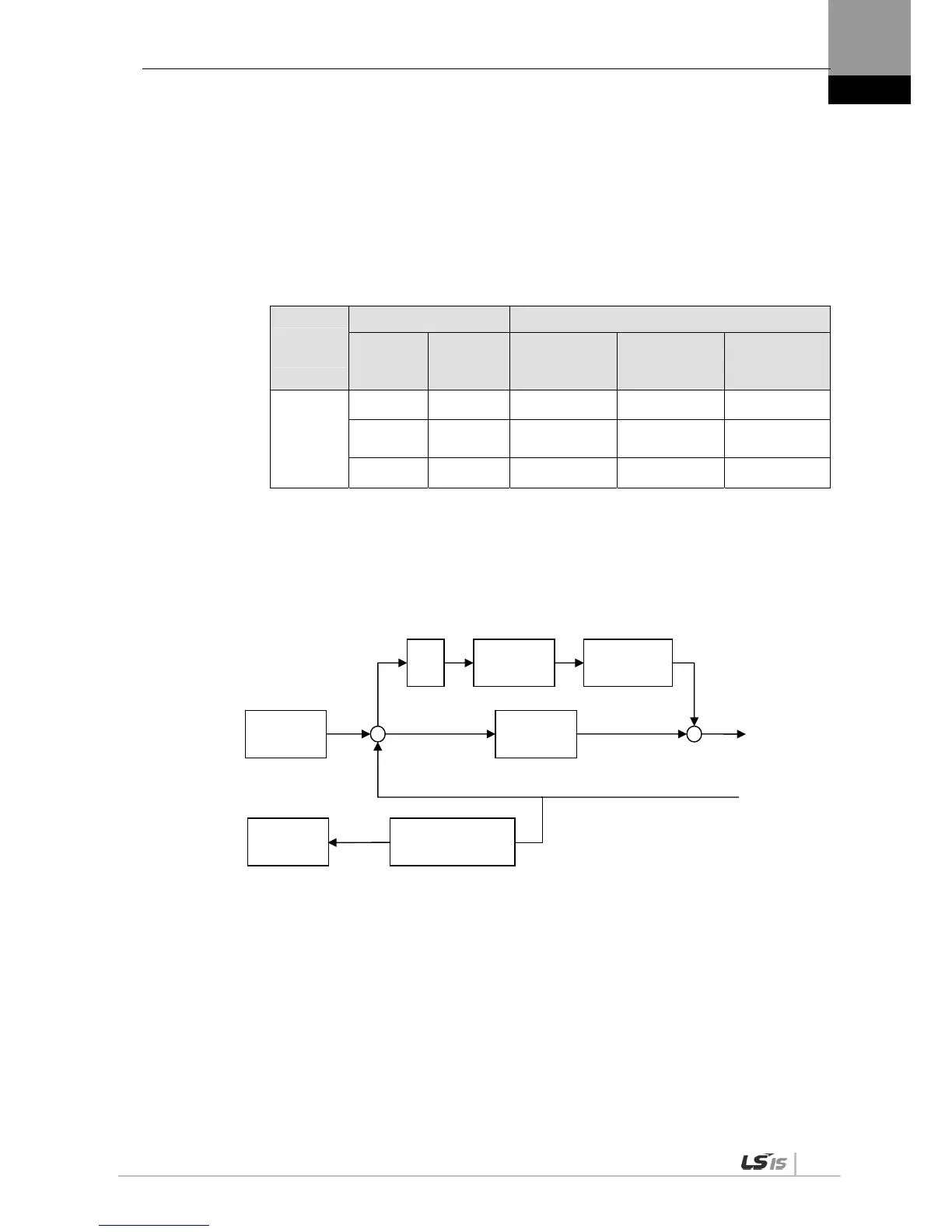

(2) Position Control Gain

Position command: Count the position command pulses entering from outside, and converts them

into position commands, apply an electric gear ratio, and then pass through [P1-03] position

command filter, and use it as an internal position command. In the case that Numerator of electric

gear is bigger, a change of external input position command pulse influences on a change of

internal position command. And this influence is getting bigger. So there is need to adjust ‘[P1-03]

position command filter time constant’

Current position: Count pulse signals received from the encoder and convert them to current

position by using electronic gear ratio settings.

Position proportional gain [P1-01] and [P1-02]: Convert the difference between the position

command and the current position into a speed command by multiplying it by position proportional

gain.

* Recommended value = speed proportional gain [P1-06] / 10

Differ

entiati

on

FF filter time

constant

Feedforward gain

[P1-04]

Current position

Proportional

gain

Position error

+

-

+

+

Speed

Command

Position

command

Pulse output

Prescale

[P0-14]

Loading...

Loading...