4. Parameters

4-56

1 : 0~+10V

DIGIT 5 -> Sets EEPROM save function in communication.

0: EEPROM use.

1: EEPROM not for use

17. DAC output setting

There are 2 kinds of DAC output, each of which is made every 200 [usec] according to the condition

of used data.

DAC output type [P0-18 DIGIT 1, DIGIT 2]

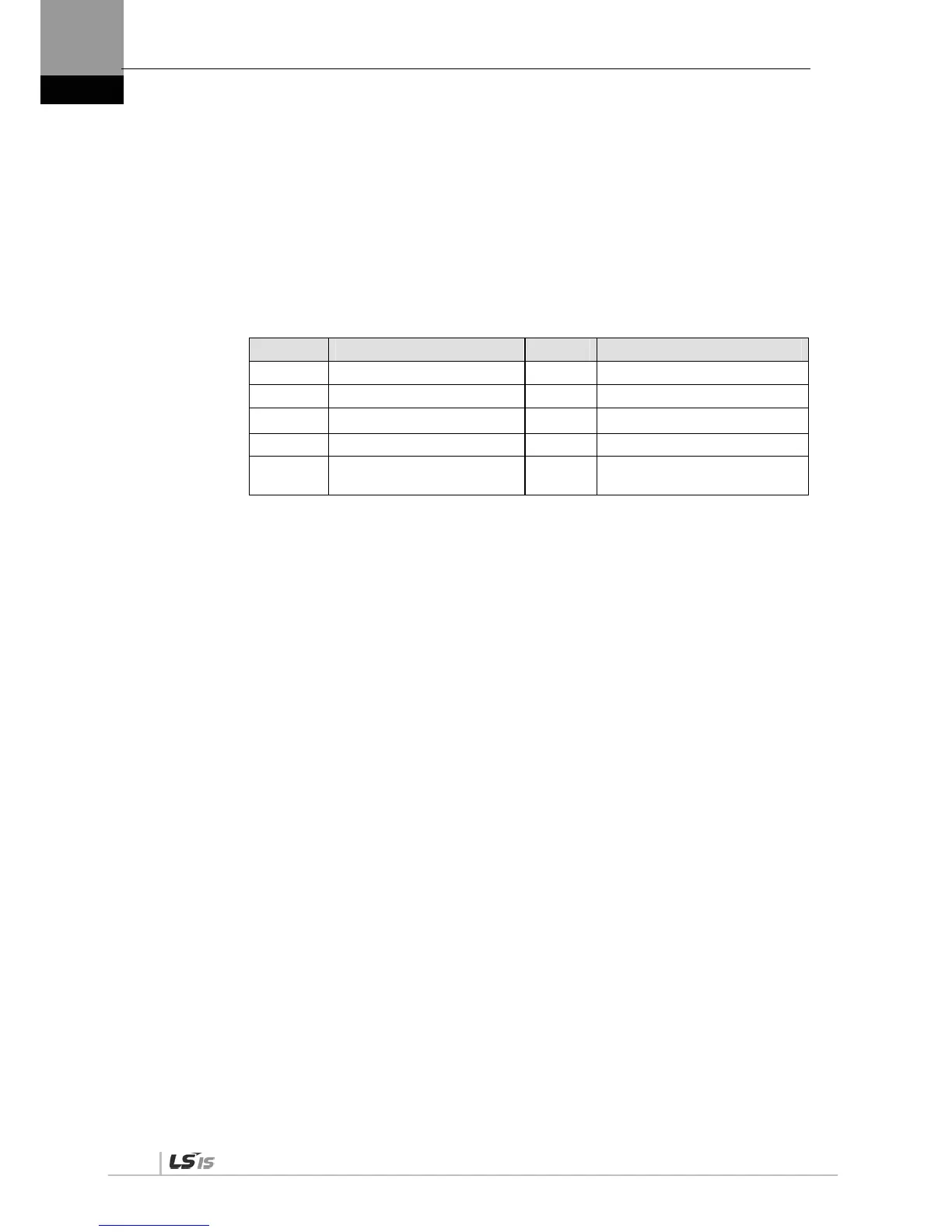

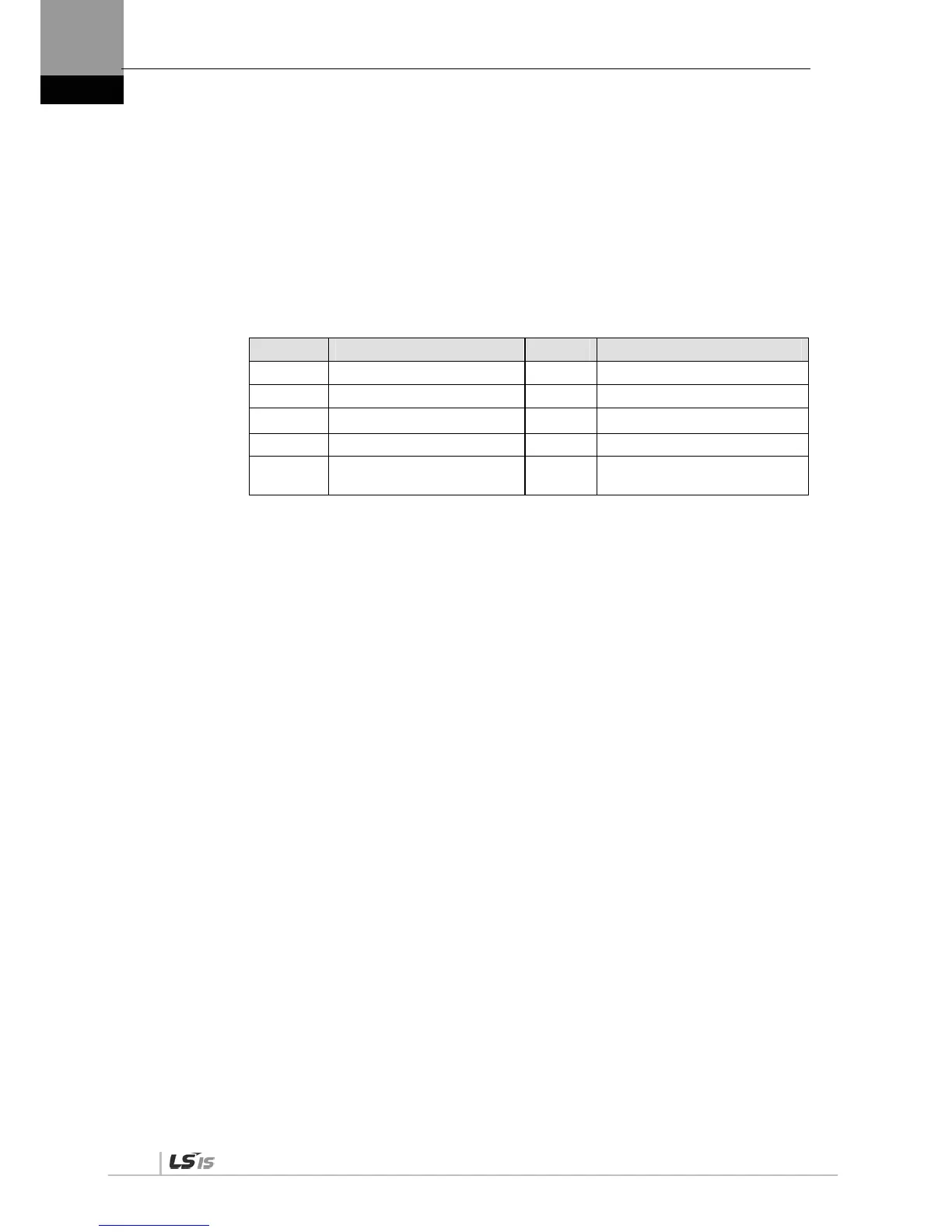

Type Data Content Type Data Content

0 Speed feedback [RPM] 5 Following error [pulse]

1 Speed command [RPM] 6 DC link voltage [V]

2 Torque feedback [%] D Speed command (user) [RPM]

3 Torque command [%] E Torque command (user) [%]

4

Position command frequency

[0.1 Kpps]

DAC output scale[P0-23], [P0-24]

If the output value is too low or too high, output ratio can be adjusted.

Sets magnification [Unit/V] for analog output channels 1 and 2.

(Speed [RPM], torque [%], position command frequency [0.1 Kpps], position [pulse], DC link [V])

Example) Channel 1 scale 100 =>100 [RPM] is output as 1 [V].

DAC output offset [P0-19], [P0-20]

Sets offset [Unit/V] for 1 ~ 2 analog output channels.

(Speed [RPM], torque [%], position command frequency [0.1 Kpps], position [pulse], DC_Link

[V])

4.4.2 Control Parameter Setting

The order of setting control parameters is as follows:

Load inertia ratio [P1-00] setting: Refer to “5.2.6 Auto Gain Tuning [Cn-05].”

Position proportional gain [P1-01] and [P1-02] adjustment:

Increase the gain to the extent that the servo motor does not overshoot or take off (do not use

during speed operation or torque operation).

Speed proportional gain [P1-06] and [P1-07] adjustment:

Increase the gain to the extent that the servo motor does not vibrate.

Speed integral time constant [P1-08] and [P1-09] adjustment:

Refer to the following table and perform setting according to the speed proportional gain.

Loading...

Loading...