4. Parameters

4-58

Feedforward gain [P1-04]: Calculate the gradient with the differential value of the position command.

Reduce time to target position by adding the speed command to the gradient. If the resultant

value is too big, overshooting or instability might occur in position control. Therefore, it is important

to gradually increase the value from a small value while watching the test drive.

Feedforward filter [P1-05]: If position commands change too drastically, the feedforward control

filter vibrates. In this case, set a filter value to remove the vibration.

(3) Speed Control Gain

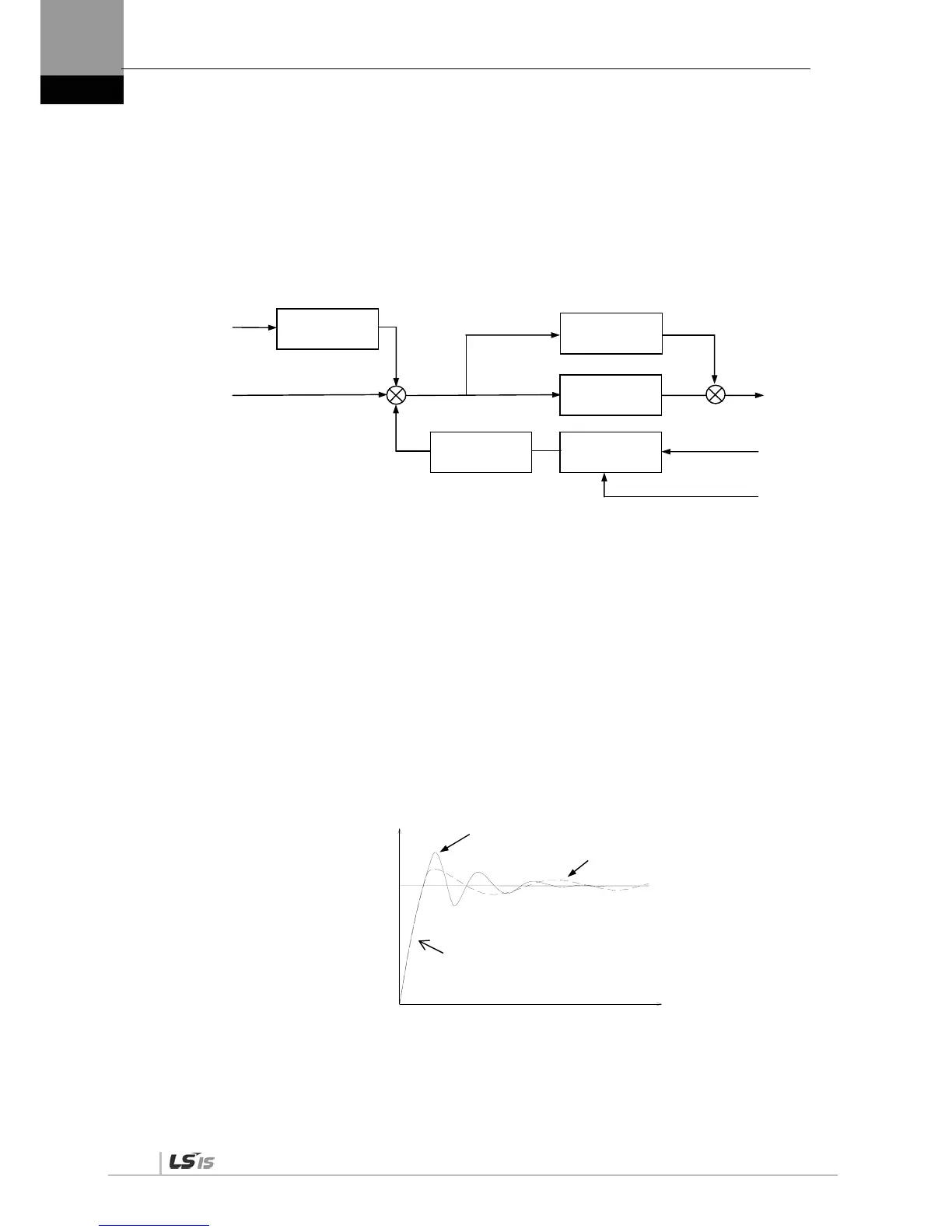

Speed command: Use an analog speed signal entering from outside as a speed command after

running it through the speed command filter [P1-10], or use a digital speed command and [RPM]

set in the internal parameter.

Current speed: Calculate speed by counting encoder signals as time progresses, and use the

calculated speed as the current speed after running it through a filter. An algorithm, which projects

speed by using the current torque and inertia, is used to make up for the errors occurring during

speed calculation at a very low speed. Therefore, an accurate motor constant and inertia ratio are

closely associated with the stability of motor speed control.

Speed integral time constant [P1-08]: Calculate the integral value of the speed error, which is the

difference between the command and the current speed, and convert it into a torque command by

multiplying it by integral time constant.

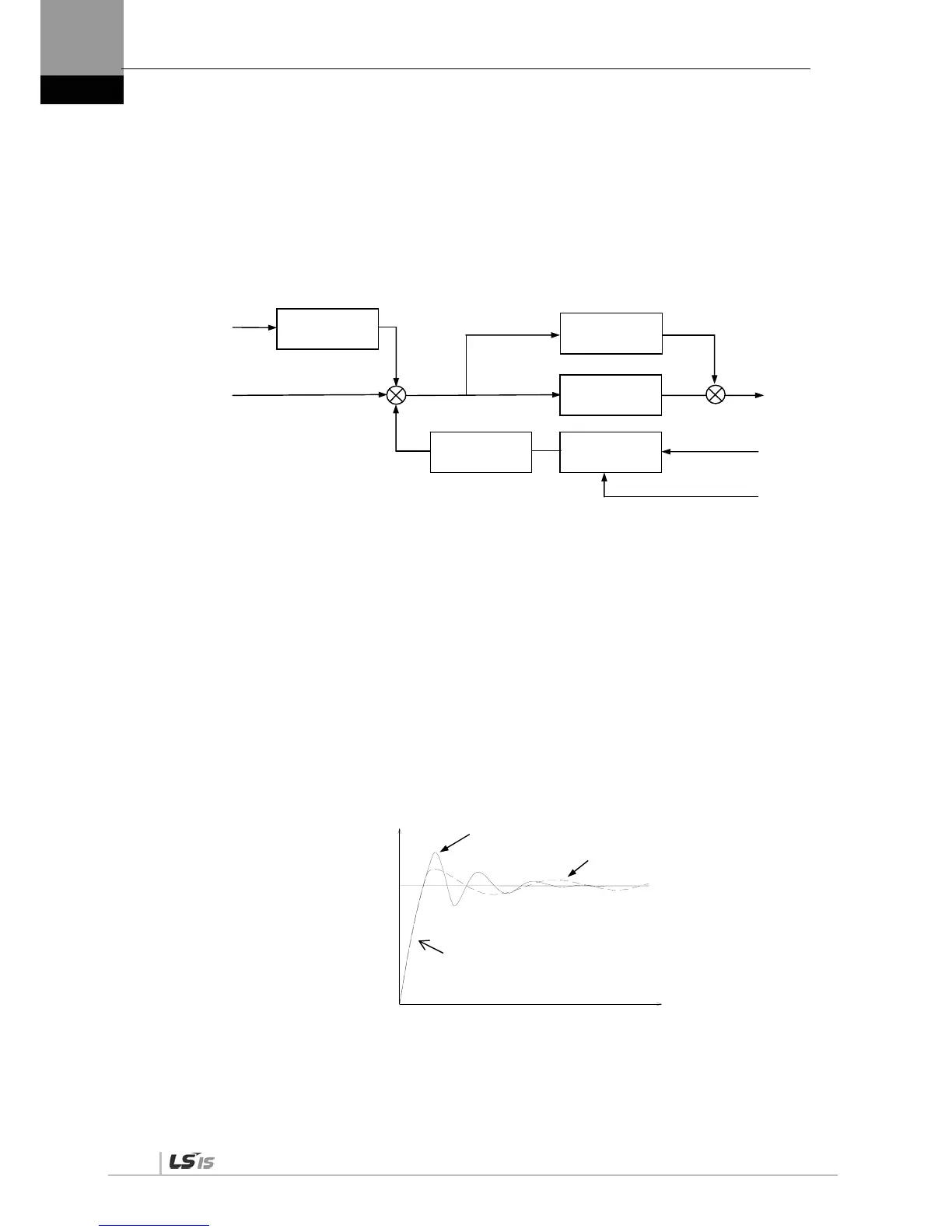

A decreased integral time constant solves the transient response issue and thus improves speed

tracking. If the integral time constant is too small, however, overshoot occurs. On the other hand,

if the integral time constant is too big, excessive response drops and proportional control takes over.

* Recommended value = 10000 / speed proportional gain [P1-06]

Speed proportional gain [P1-06]: Convert the speed error into a torque command by multiplying it

by proportional gain.

If the result value is large, speed response accelerates and thus speed tracking increases. If the

value is too big, however, vibration occurs. If the value is too small, speed response slows down

and speed tracking decreases. Consequently, the servo loses its power.

Analog

speed

command

Speed command

filter time constant

[P1- 10]

Speed integral

time constant

Loading...

Loading...