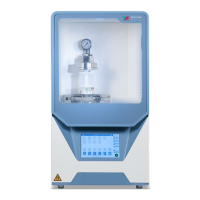

Milestone Srl MA245-003 – ultraWAVE 3 – User Manual

22

the maximum operating limits of the equipment. Preliminary tests with smaller sample quantities are

required.

Do not use gas phase digestion applications

The use of gaseous digestion applications, particularly with the use of combustible gases such as

hydrogen or oxygen, are not admitted.

Base load and gas loading pressure

UltraWAVE 3 must always be operated with a base load (minimum i.e. 100 ml Water) and gas loading

pressure (min. approx. 25 bar). Operating gas to be used is Nitrogen or Argon.

Pressure vessel must be opened latest 30 minutes after cooling and cleaned up. It is suggested

to avoid that acid vapours remain for several hours in the system, as this can lead to corrosion.

Aggressive Media

When using aggressive media, the entire pressure system has to be regularly checked for corrosion.

These checks can be accomplished in the frame of a technical service inspection through a Milestone

authorized representative. The specially marked components (lines/tubing, valves, etc.) are subject to

regular check and maintenance.

Pre-loading Pressure

Use N

2

or Ar (Nitrogen) as loading gas of the reactor (pressure loading).

Compressor or Booster supplied by Milestone works with both Nitrogen or Argon gas.

Do not use air as gas. This may originate strong gas-phase reactions, caused by oxygen content and

particularly for those samples that are floating on the surface or cannot be diluted with reagents. These

reactions can lead to burning of the PTFE parts inside the pressure vessel.

Spontaneous reactions

To eliminate or reduce spontaneous reactions the following steps are to be taken:

• To ensure/optimize a better homogenization of the sample by stirring, agitating or by

ultrasounds. Homogenization before starting the reaction is required for all reactions.

• Dilute the digestion solution, especially with increased sample weight.

• Increase the time of the first step (temperature ramp time).

• As additional preventive measure uses whenever possible disposable glass / quartz vessels.

• It is imperative to adopt these measures for all samples with lower density than the reagents

(floating on the surface).

Pressure line

Follow these basic guidelines to ensure protection of hoses and lines in the ultraWAVE 3 pressure system:

• Never exceed the specified pressure of max. 199 bar. Recommended maximum operating

pressure is 160 bar.

• Do not use hoses outside the specified temperature range (-55 °C up to +200 °C).

• The hoses must be checked at regular intervals for damages, such as cuts, leakage, and

abrasion, bubbles of the liners as well as defective or loose connections.

Loading...

Loading...