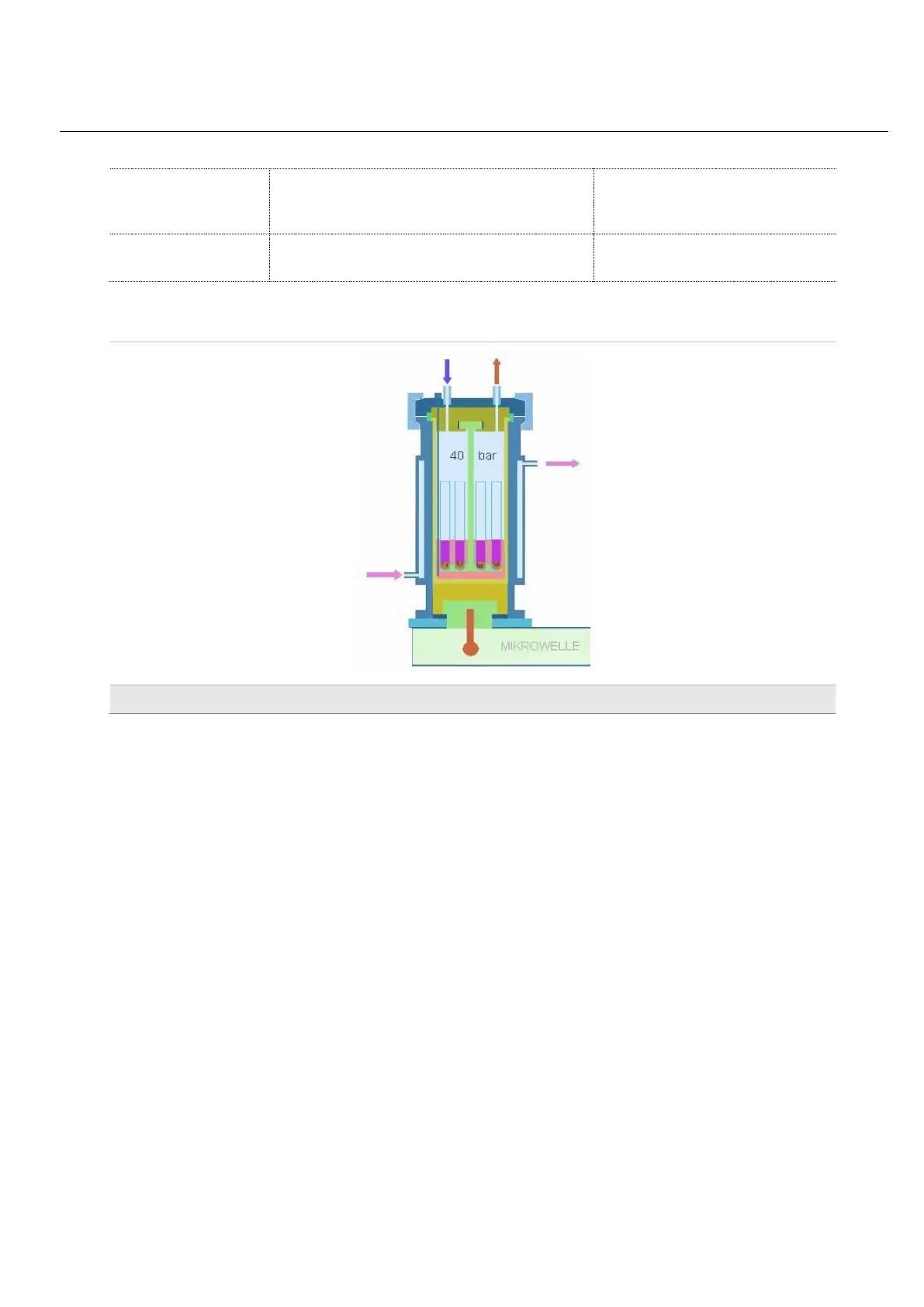

ultraWAVE 3 consists of a water-cooled high-grade stainless-steel reactor completely PTFE coated. Based

on its patented technology the reactor - despite the extremely high internal temperature - remains under

60°C, which makes its structure even more resistant to the most corrosive media.

The pressure vessel is made of special stainless steel and is closed with a clamping device.

The samples together with the necessary acid mixture are filled into commercially available quartz, glass

or PTFE vials and loosely covered with a cap. With the available sample holders, it is possible to

simultaneously process 15 (standard holder) to 22 samples depending on vessel size.

The pressure vessel is pre-loaded with inter gas (nitrogen) before microwave heating. The gas pressure

increases substantially the boiling point and works as a pressure cover for each vial.

Direct microwave heating allows a fast temperature increase. During the process the vessel shield

remains cold and is further cooled down by a recirculation water cooler. This minimizes the cooling time

at the end of the program.

At the end of the digestion process the vessel pressure is automatically relieved. The cover can be

opened manually and then all vials can be taken out.

The use of commercially available standard vials allows direct transfer to the analyser’s auto sampler.

Microwave Heating

Microwave radiation is generated by a magnetron. The magnetron is connected through a waveguide to

the bottom of the pressure vessel. Microwaves are thus irradiated through the bottom of the vessel. A

safety system ensures that the microwave heating is applied only with closed pressure vessel.

Loading...

Loading...