Milestone Srl MA245-001 – ultraWAVE 3 – User Manual

75

Vessel Covering

At the End of the working day, before the unit switching off

Leave the PTFE vessel in the reactor when the unit is off. This is to protect the reactor from

any dust or condensation.

In case there is high humidity in the laboratory, it is recommended to put some absorbent paper on the

reactor

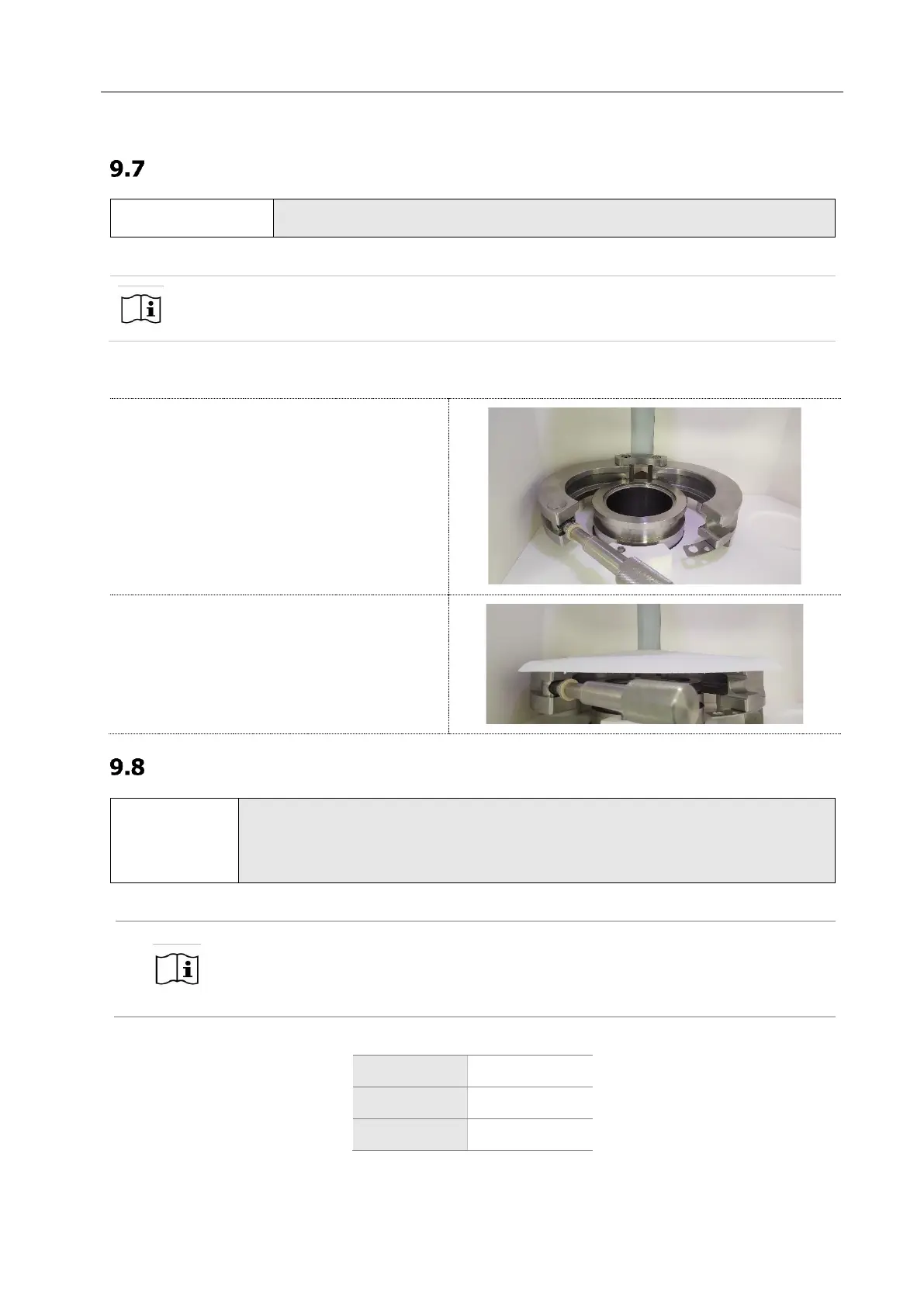

The clamps are carried in the position

represented in this picture. Pay attention that

the pressure vessel and the locking bolt are

not in direct contact each other, otherwise

there will be no drying process.

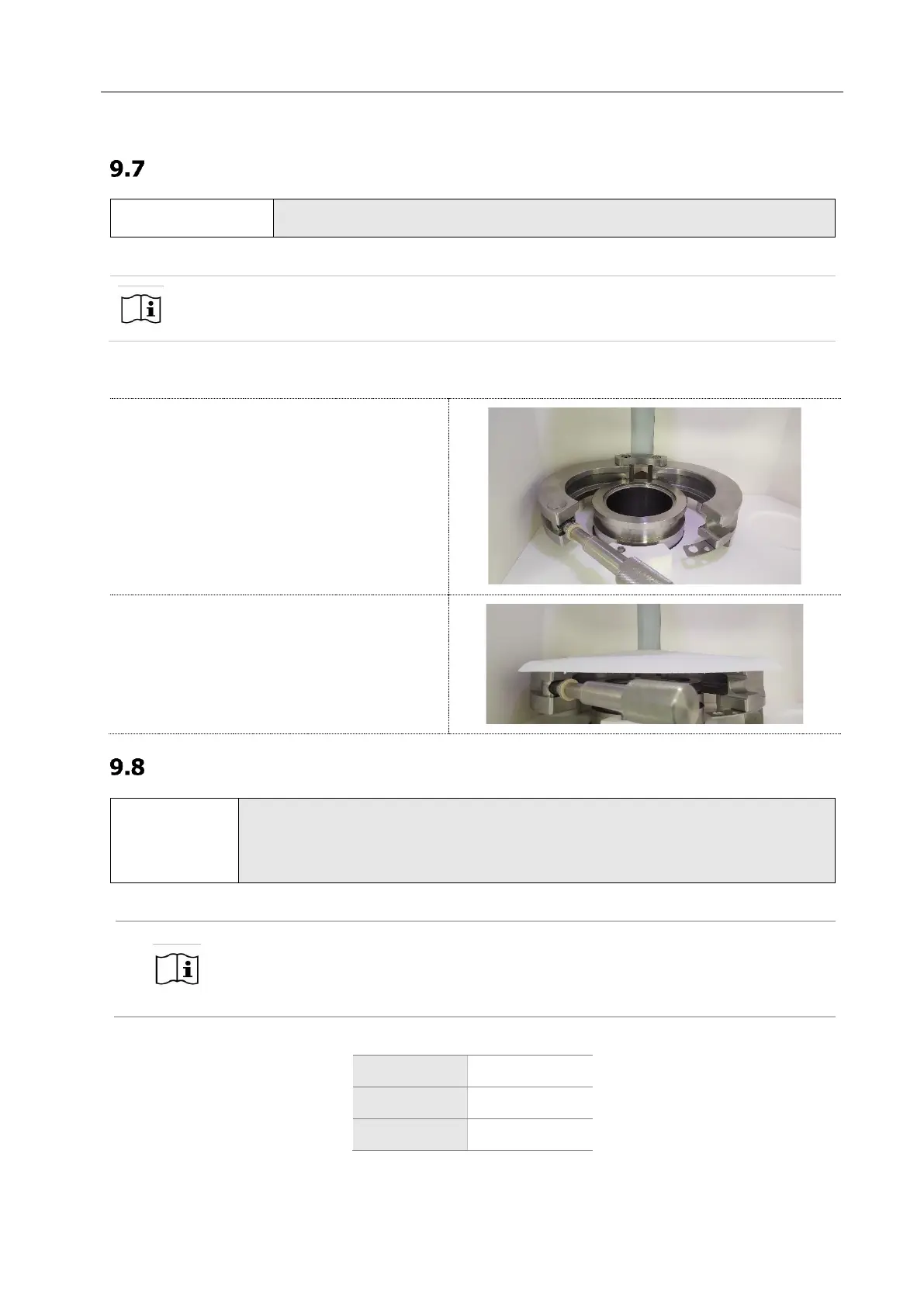

Place absorbent paper sheet on the clamps.

The paper cannot completely seal the pressure

vessel, so that the remaining moisture can

leak from the vessel.

Leak Test of the main reactor

In case of pressure decrease after the heating phase (when the temperature is

constant) of 0.5 bar every 10 min.

After preventive maintenance by Milestone service engineer

Leakage of the ultraWAVE 3 is tested with the following protocol. If the leak test is not

passed, it is necessary to check the installation of all parts and components like PTFE

cover and O-rings as well as PTFE-TFM rings. If the system is still leaky, consult

Milestone or local representative service.

Create the following program (for operating instructions see the Software Manual)

Loading...

Loading...