104

n Adjusting Crease Depth

1. Objective

Adjusting the depth of the crease.

• Removing the Creaser Assembly

\See page 70

NOTE :

• You need to adjust the sensor plate after

installing the creaser assembly.

• You need to adjust the creaser perpendicu-

larity and creaser calibration after adjusting

the sensor plate.

• Creaser Sensor Plate Adjustment

\See page 118

• Creaser Perpendicularity Adjustment

\See page 108

• Creaser Calibration

\See page 100

2. How to make adjustments

NOTE :

• A test sheet may be creased by inserting it in

the creaser gap and manually rotating the

creaser unit pulley.

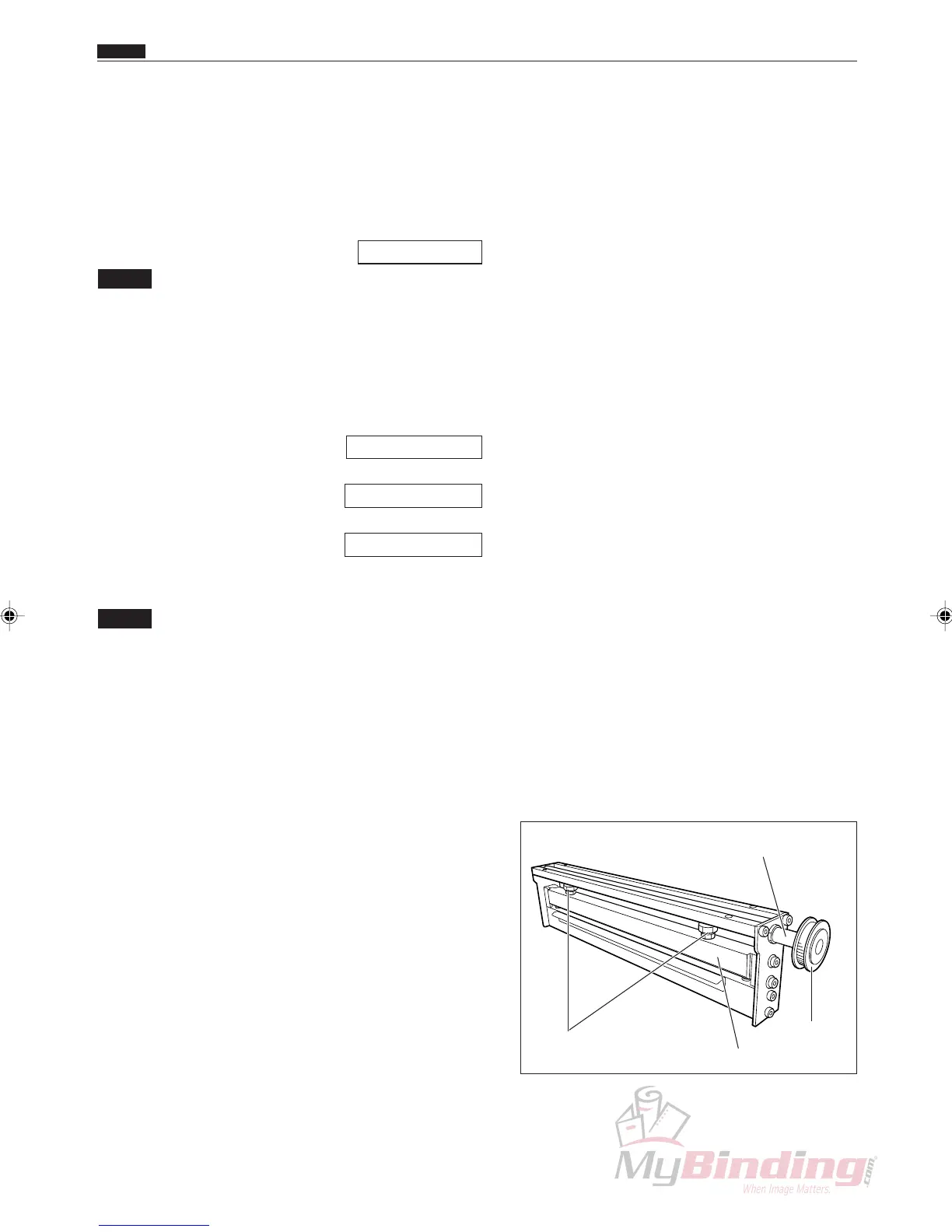

q Place the Creaser Assembly in the “upright” position

(normal operating orientation) on a stable surface.

w Loosen the two lock nuts, as shown in Figure.

e Rotate the Creaser Assembly pulley unit the eccen-

tric shaft has reached it lowest point.

r Place a 0.6 mm feeler gauge between the Creaser

Blades, making certain the gauge does not interfere

with the raised area on the male creaser blade.

Rotate each adjusting bolt clockwise to increase the

gap size (or counterclockwise to decrease the gap

size).

t Tighten each lock nut while holding the respective

adjusting bolt.

y Verify the gap size and readjust if necessary.

n Adjusting Crease Depth

Chap.4

Eccentric Shaft

Pulley Unit

Upper Blade

Lock Nuts

Loading...

Loading...