120

z Cleaning and Oiling

(1)Cleaning

1.Paper shreds

Clean with a brush or a dry cloth.

(2)Oiling

1.Bearings

Apply a small amount of oil to the end face and axel while turning the levers and rollers.

2.Gears and Rails

Apply grease after cleaning the paper dust off of the gears.

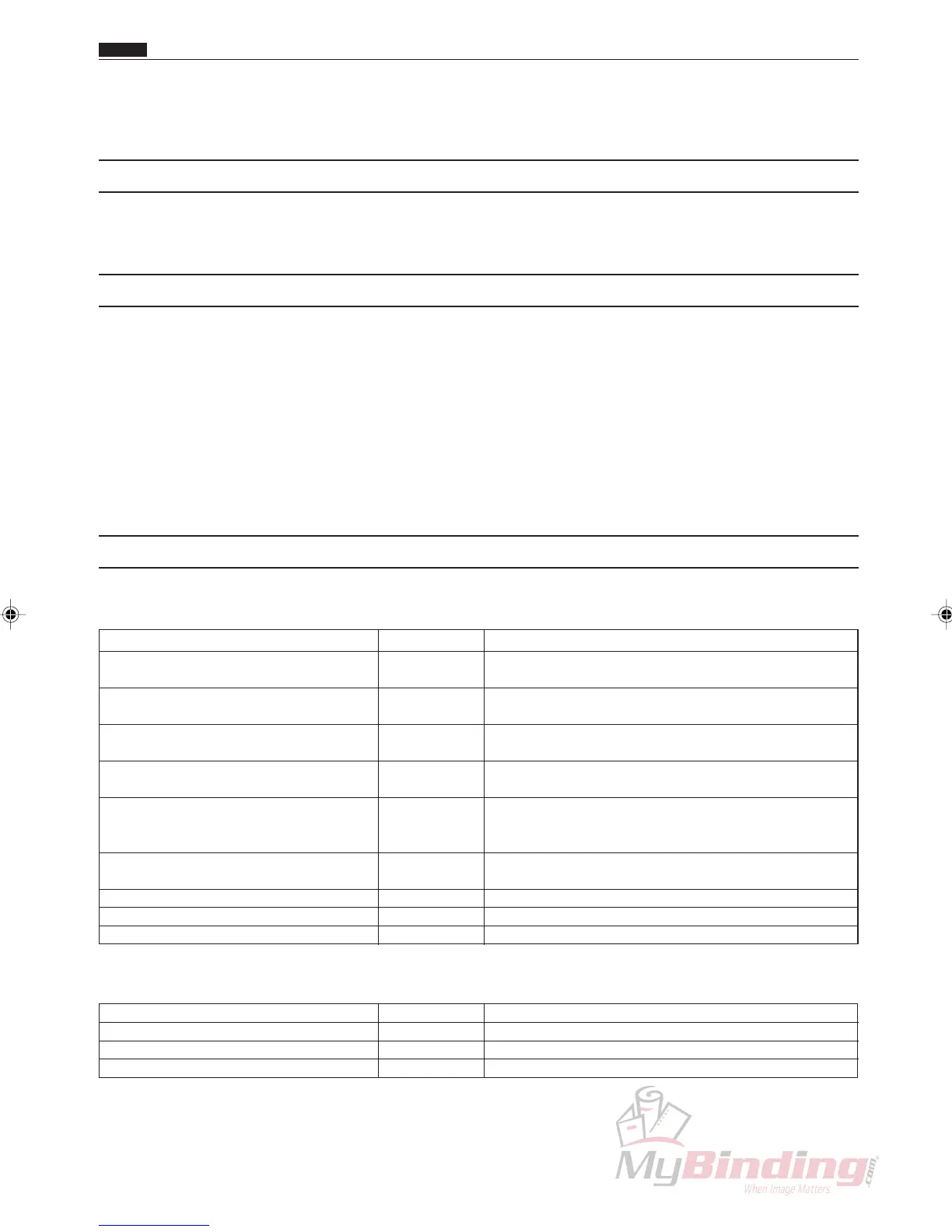

x Periodic Maintenance Check List

(1) 6-month Periodic Checks

1. DC-545

Section to be checked Description Inspection standard

PPS1 Cleaning Use a brush to clean any paper dust, etc. from the

upper and lower sensors.

PPS2 Cleaning Use a brush to clean any paper dust, etc. from the

upper and lower sensors.

PPS3 Cleaning Use a brush to clean any paper dust, etc. from the

upper and lower sensors.

PPS4 Cleaning Use a brush to clean any paper dust, etc. from the

upper and lower sensors.

Timing Belts Checking Inspect Belts for signs of wear or loss of tension.

Replace any cracked or worm belts, and retension as

required.

Rollers Cleaning Use a lint-free cloth moistened with water to clean the

rollers.

Roller Bearings Oiling Oil (70P95)

Slitter Oiling Oil (70P95)

Cutter Oiling Oil (70P95)

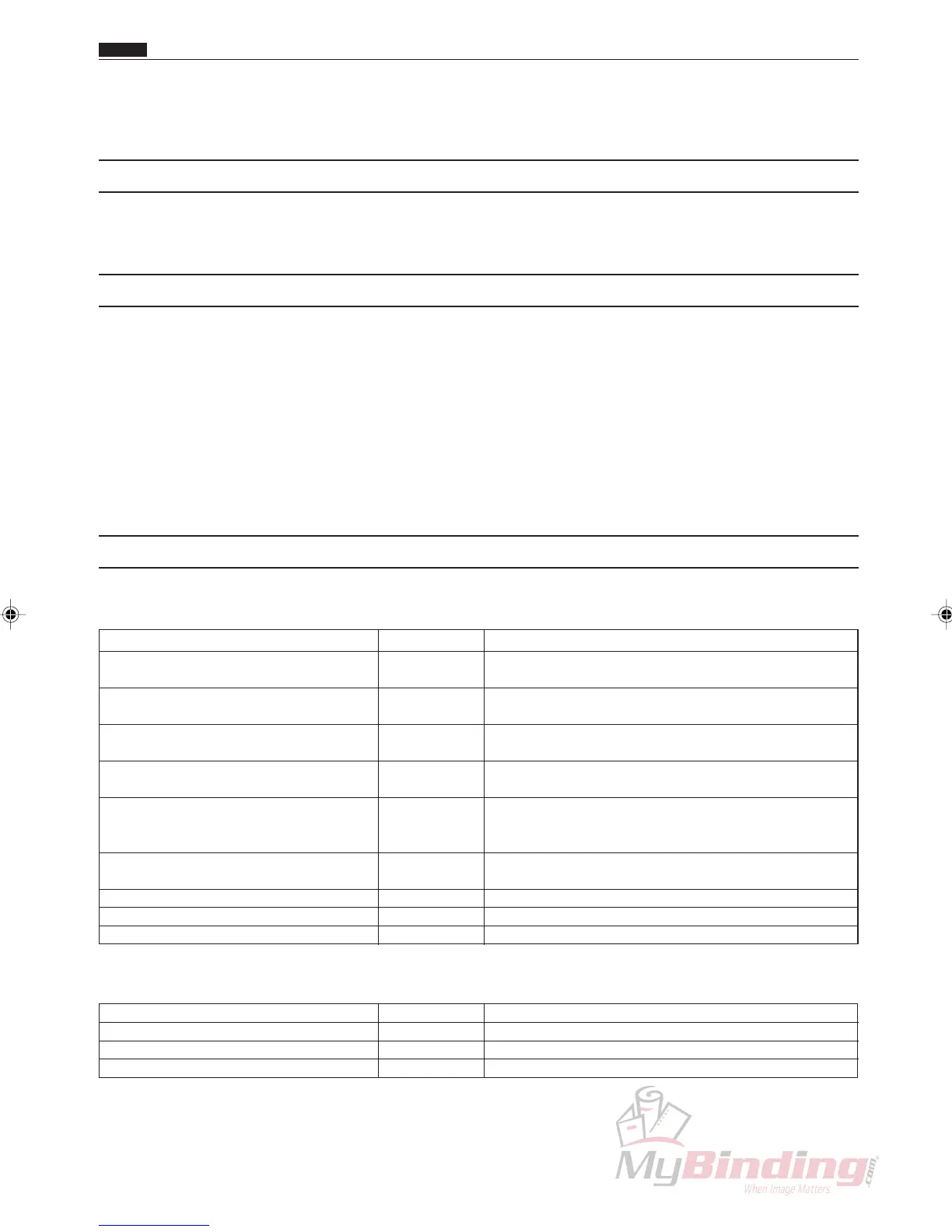

2. AF-100

Photo Emitting Sensor (N4-W1091) Cleaning Use a brush to clean any paper dust, etc.

Photo Receiving Sensor (N4-W2061) Cleaning Use a brush to clean any paper dust, etc.

Flat Belts Cleaning Use a brush to clean any paper dust, etc.

Gears Greasing

Chap.5

z Cleaning and Oiling x Periodic Maintenance Check List

Loading...

Loading...