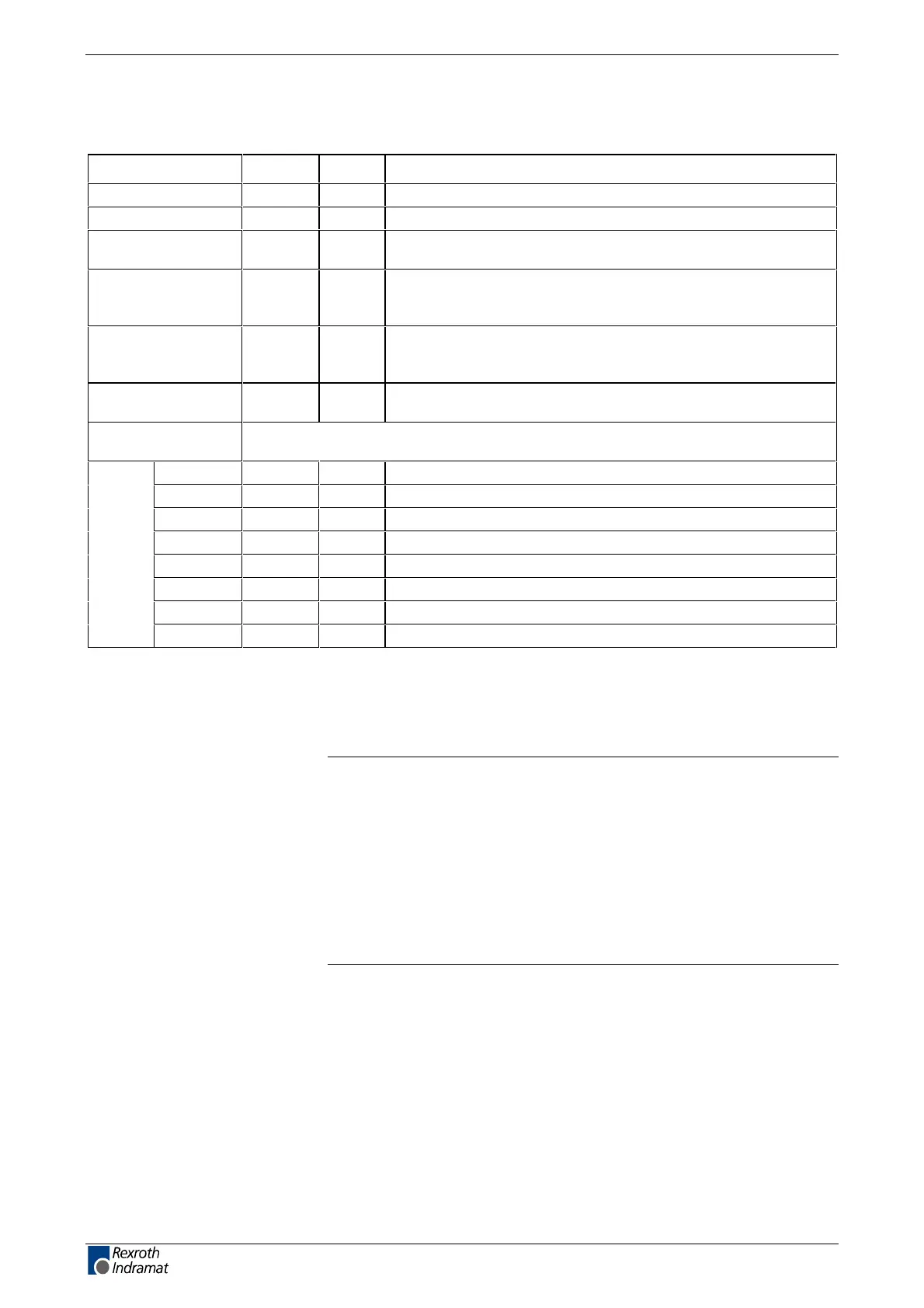

5-6 srellortnoC evirD 30EVIRDOCE610-3.**CKD 30EVIRDOCE

Control voltage connection

(Data applies to ambient temperature of 25 °C)

WF-7-610-3.**CKDtinUlobmySnoitangiseD

Control voltage U

N3

V )8.82 ... 2.91( CDV

egnar egatlov tupni deecxe ton yamwtceffe elppir .xam

max. allowed

overvoltage

U

N3max

* evititeper non ,sm 1 rof V 54V

)

max. charging

current

I

EIN3

2A

(see diagram on page 5-7 "Charging current prole of control

voltage"

)

max. pulse duration

of I

EIN3

t

N3Lade

06sm

(see diagram on page 5-7 "Charging current prole of control

voltage"

)

max. input

capacitance

C

N3

2.1 x 0.3Fm

Power consumption

(X1)

dependent on type of unit, without external load at control outputs and

encoder interface 2

DKC01.3 P

N3

51W

DKC02.3 P

N3

51W

DKC03.3 P

N3

61W

DKC04.3 P

N3

71W

DKC05.3 P

N3

61W

DKC06.3 P

N3

61W

DKC21.3 P

N3

61W

DKC22.3 P

N3

61W

Fig. 5-5: Control voltage connection for DKC**.3-016-7-FW

*

)

To be obtained by appropriate mains sections and shielded wire routing.

Connections for control voltage: see page 5-19 "X1, Connections for

control voltage".

Note: Overvoltages of more than 45 V have to be derived by

measures in the electrical equipment of the machine or

installation. This includes:

• 24-Volt mains sections that reduce incoming overvoltages

to the allowed value.

• Overvoltage limiters at the control cabinet input that limit

existing overvoltages to the allowed value. This also

applies to long 24-Volt lines that have been laid in parallel

with power and mains cables and can absorb overvoltages

caused by inductive or capacitive coupling.

customerservice@hyperdynesystems.com | (479) 422-0390

Loading...

Loading...