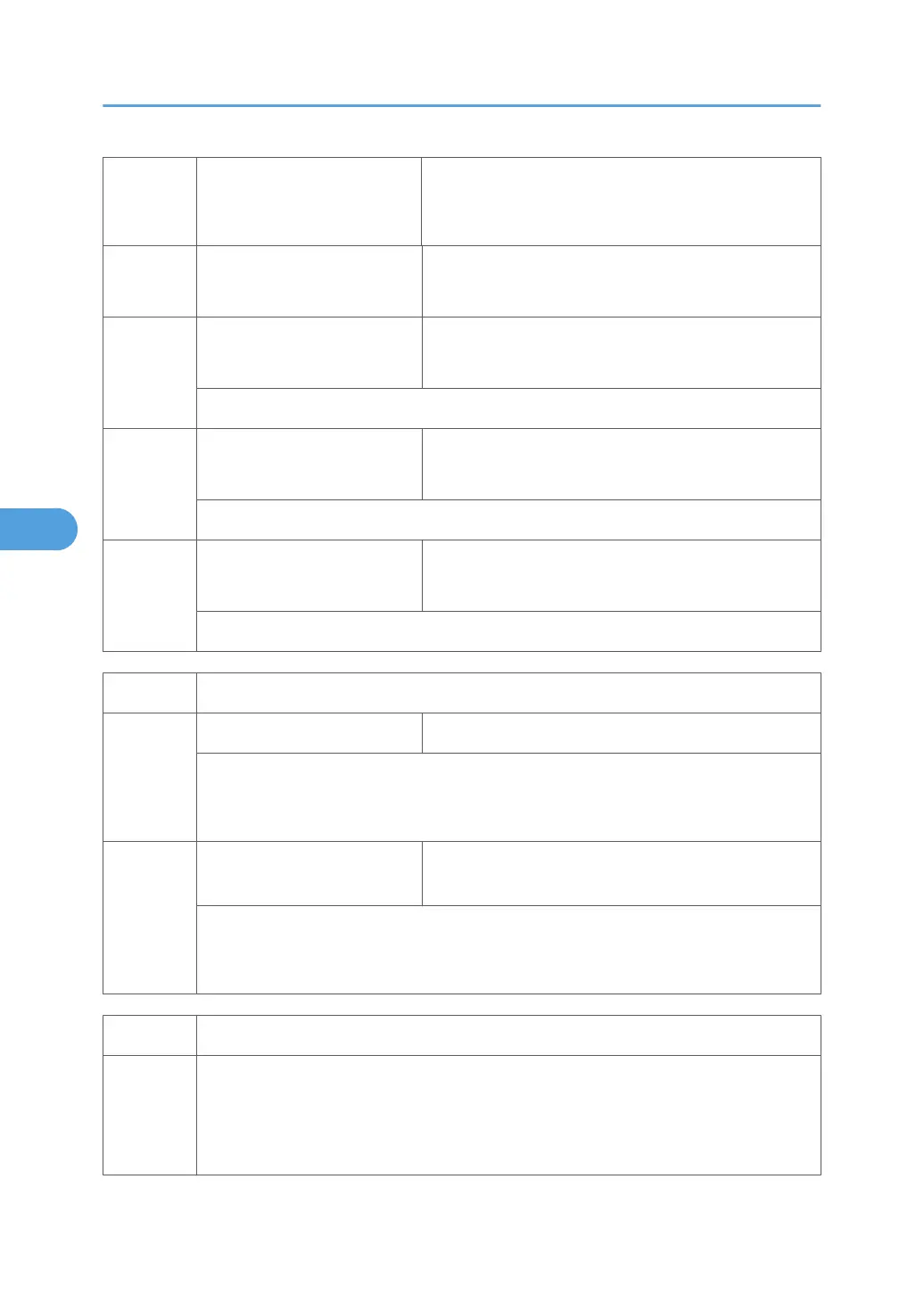

2101* Erase Margin Adjustment

Adjusts the width of the erased area (* "Adjusting Copy

Image Area" in the section "Replacement and

Adjustment").

2101 1 Leading edge

[0.0 to 9.0 / 3.0 / 0.1 mm/step]

Specification: 2 ± 1.5 mm

2101 2

Trailing

[0.0 to 9.0 / 4.0 / 0.1 mm/step]

Specification: 2 +2.5/–1.5 mm

The rear trailing edge is this value plus 1.2 mm.

2101 3

Left side

[0.0 to 9.0 / 2.0 / 0.1 mm/step]

Specification: 2 ± 1.5 mm

The rear left edge is this value plus 0.3 mm.

2101 4

Right side

[0.0 to 9.0 / 2.0 / 0.1 mm/step]

Specification: 2 +2.5/–1.5 mm

The rear right edge is this value plus 0.3 mm.

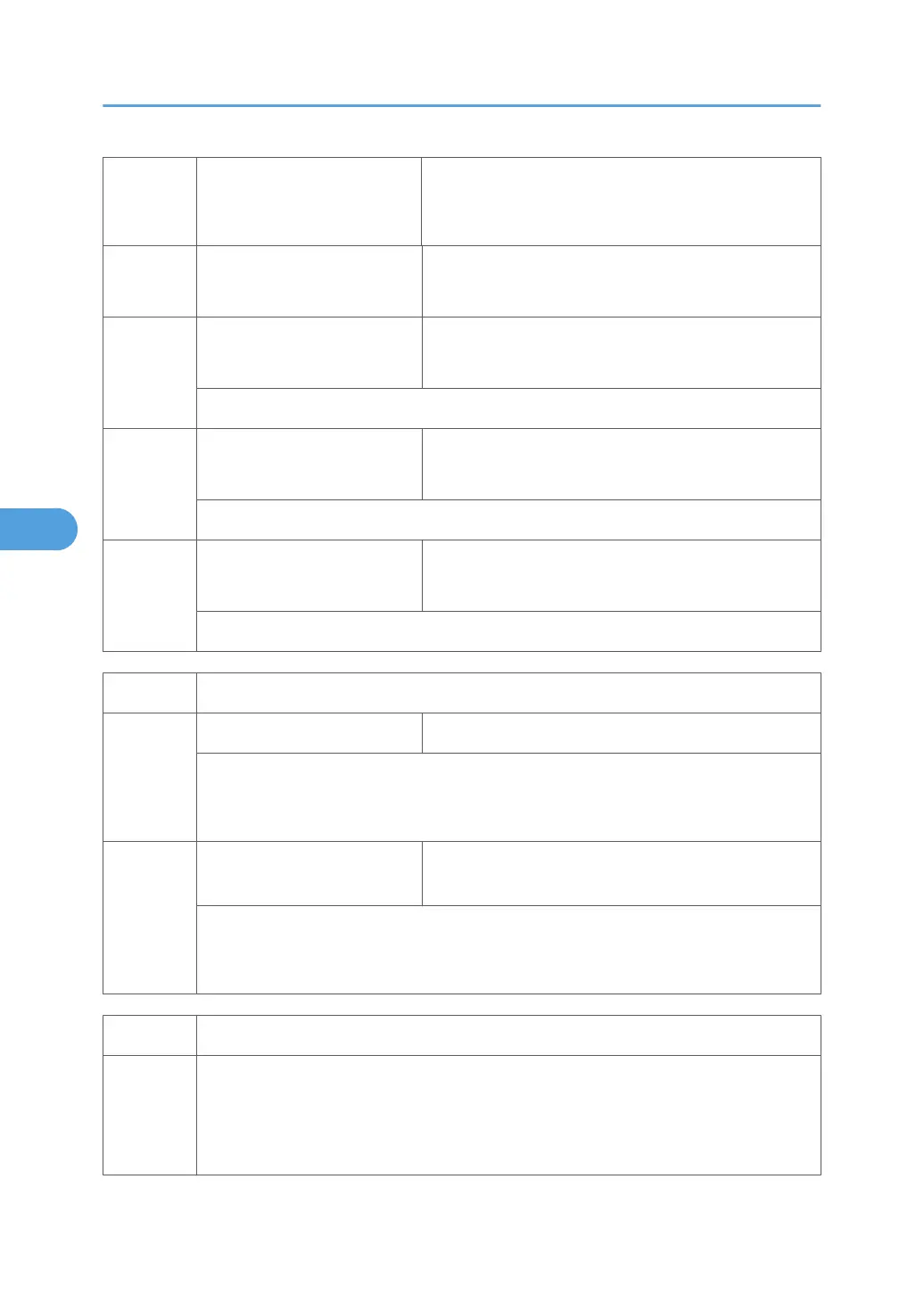

2201* Development Bias Adjustment

2201 1

Printing [–1500 to –200 / –650 / 1 V/step]

Adjusts the voltage applied to the development roller for printing. Image density becomes

higher when you specify a smaller value (a greater absolute value). Image density becomes

lower when you specify a greater value (a smaller absolute value).

2201 2

ID sensor pattern

[–2 = LL (220 V) / -1 = L (260 V) / 0 = N (300 V) / 1

= H (340 V) / 2 = HH (380 V)]

Adjusts the voltage applied to the development roller for the ID sensor pattern. The voltage

applied is obtained by adding SP2-201-002 to SP2-201-1. The setting affects ID sensor

pattern density, which in turn affects the toner supply.

2213* Outputs after Near End

2213 1

[0 = 50 pages / 1 = 20 sheets]

Sets the number of copy/print/fax pages that can be made after toner near-end has been

detected. Reduce the number of pages if the user normally makes copies with a high image

ratio.

5. Service Tables

138

Loading...

Loading...