System parameter group 00

PARAMETER DESCRIPTION 57

5.1.7 PWM carrier frequency

The motor sound can be changed by adjusting PWM carrier frequency properly.

15K/18.5KF and above Heavy Duty

15K/18.5KF and above Normal Duty

Soft-PWM

carrier function

selection

When 00-11(P.72)<5,Soft-PWM is on(only apply to V/F control)

When 00-11(P.72)>9, if the IGBT temperature is higher than

60°c, carrier frequency will decrease automatically, when

temperature go back to under 40°c, carrier frequency go back

to 00-11(P.72) value.

Carrier frequency

The higher the carrier frequency, the lower the motor acoustic noise, but will result in greater leakage current and

larger noise generated by the inverter.

The higher the carrier frequency, the more energy inverter will consume, and temperature will also be higher.

If mechanical resonance occurred in a system, 00-11(P.72) can also be adjusted to lower the vibration.

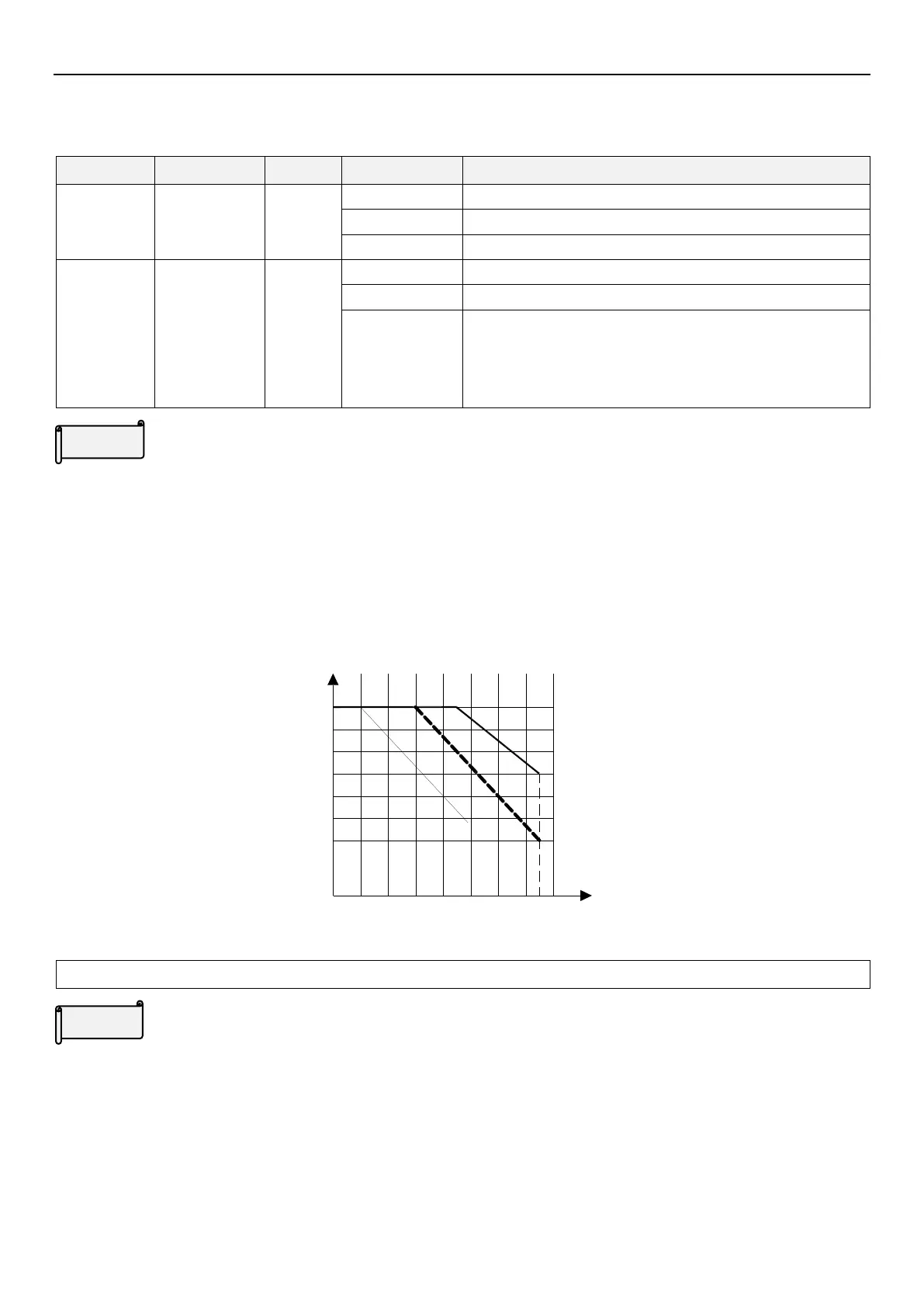

The higher the carrier frequency, the lower the rated current of the inverter. This is to prevent the inverter from

overheating and prolong the service life of the IGBT, so such protective measures are necessary. The relationship

curve between rated current and carrier frequency is shown in the figure below:

Rated current

40%

50%

60%

70%

80%

90%

100%

2kHz

Carrier frequency

4kHz 6kHz 8kHz 10kHz 12kHz 14kHz 16kHz

Note: The setting value of carrier frequency is best to be 8 times larger than the target frequency.

Carrier operation selection V/F

Soft-PWM control is a control method that changes the motor noise from a metallic sound into an inoffensive,

complex tone.

Motor noise modulation control is when the inverter changes its carrier frequency from time to time during

operation, metal noises generated by the motor will not be in a single frequency, so sharp single frequency noises

will be reduced.

This action is only valid under V/F control, that is, it is valid when 00-21 (P.300)=0.

The corresponding frame is as

follows:

A/B frame

C/D frame Heavy Duty

Loading...

Loading...