7.7.1 Pulses per cm travel that are output by the incremental encoders

Overview

T

he result depends on the number of pulses the incremental encoder supplies per rev‐

olution. It also depends on the ratio between the wheel on the vehicle and the friction

wheel on which the incremental encoder is mounted.

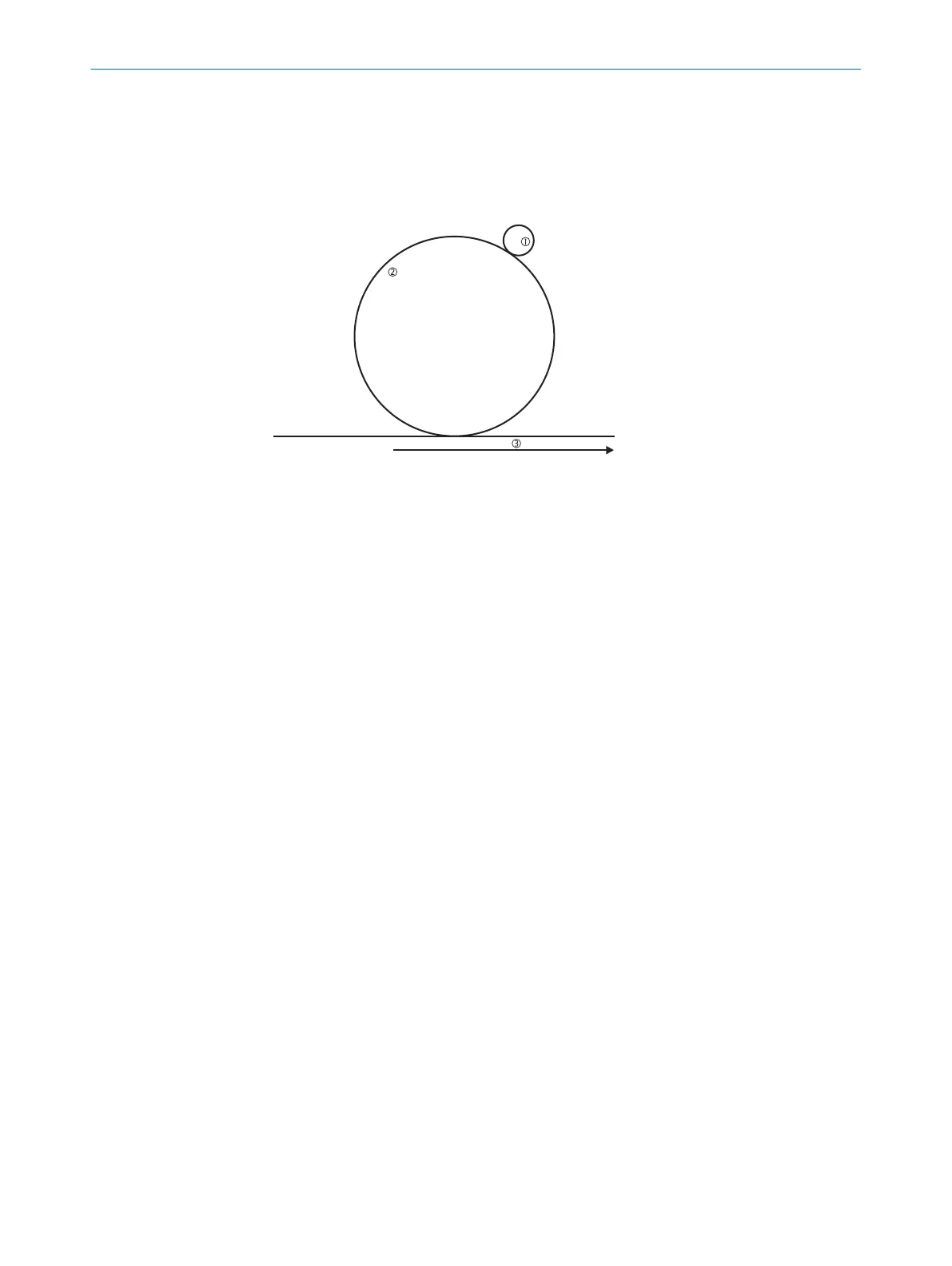

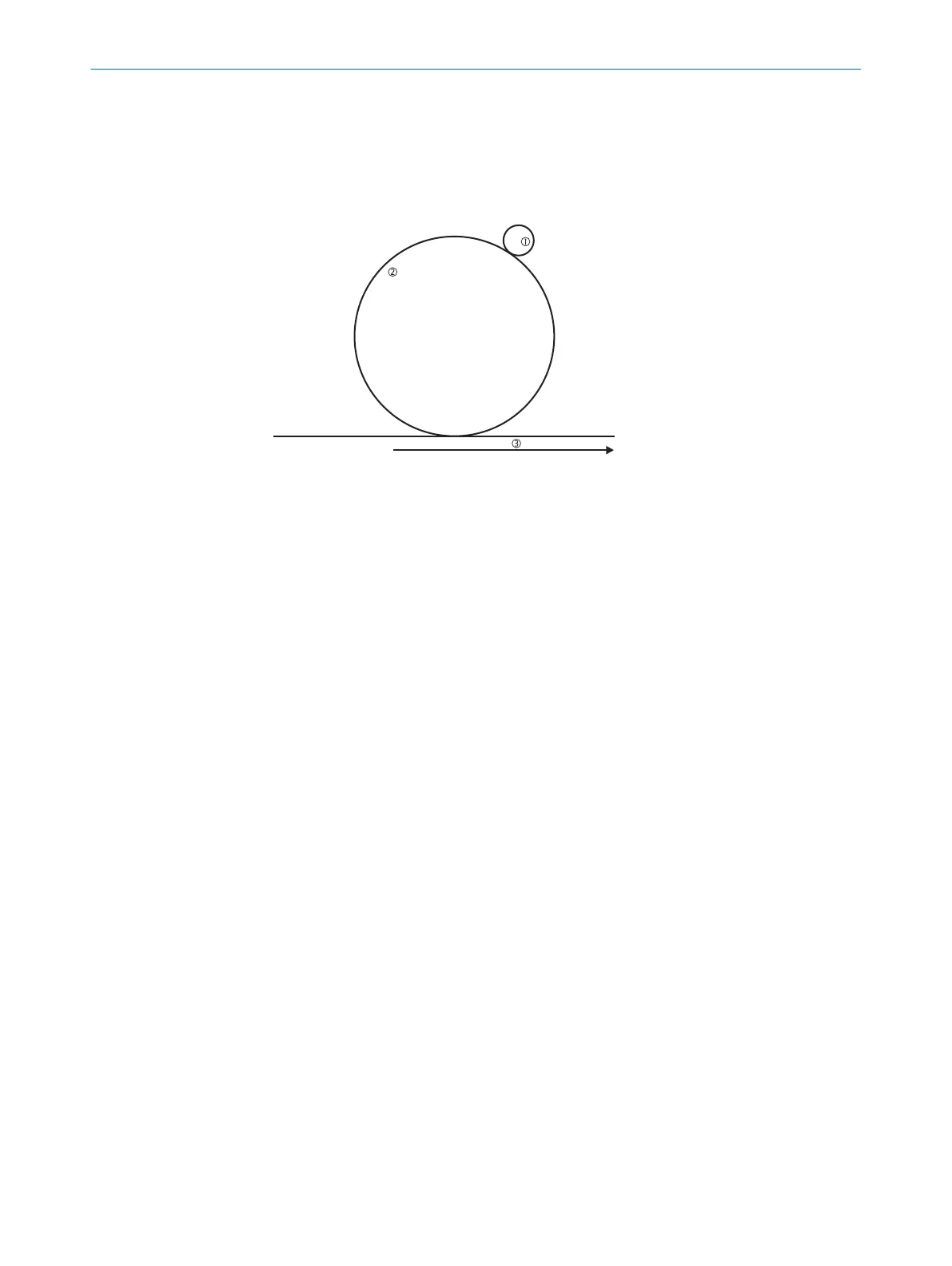

Figure 58: Calculation of pulses per cm travel

1

Friction wheel ø 3.5 cm

2

Forklift truck ø 35 cm

3

Distance covered by the AGV

Calculating the number of pulses per centimeter

Ex

ample:

•

The wheel on a forklift truck has a diameter of 35 cm.

•

The friction wheel on which the incremental encoder is mounted has a diameter of

3.5 cm.

•

The incremental encoder used supplies 1,000 pulses per revolution.

Circumference of the forklift truck wheel = d × π = 35 cm × π = 109.96 cm

One revolution of the forklift truck wheel corresponds to ten revolutions of the friction

wheel and therefore 10,000 pulses from the incremental encoder.

The number of pulses of the incremental encoder per centimeter of distance covered

by the vehicle is therefore:

pulses/cm = 10,000 : 109.96 = 90.94

When configuring the incremental encoder in the CDS, you therefore need to enter the

rounded value “91” in the Pulses per centimeter field. The user software uses this value to

calculate the maximum permissible speed of the vehicle.

7.7.2 Tolerances allowed on the dynamic inputs

As a rule, the same pulse frequency is present at the dynamic inputs when a vehicle

mo

ves in a straight line. On driving around bends or in case of wear e.g., of the vehicle’s

tires, the values at the two inputs may, however, vary.

The speed values from the two incremental encoders may only differ from each other

by a tolerance that can be configured. Deviations are allowed only for a certain time

window depending on the speed, see figure 59, page 81.

The maximum percentage deviation between the two encoder speeds that can be con‐

figured is 45%. During this process the higher of the two speeds (irrespective of

whether with positive or negative sign) is used as the reference for this calculation as

well as the vehicle speed.

7 C

ONFIGURATION

80

O P E R A T I N G I N S T R U C T I O N S | S300 8010948/ZA21/2020-06-18 | SICK

Subject to change without notice

Loading...

Loading...