Important information

DANGER

In t

he case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

The minimum distance to the hazardous area depends on the monitoring situation.

b

Make sure that the minimum distance to the hazardous area is maintained for

each monitoring case.

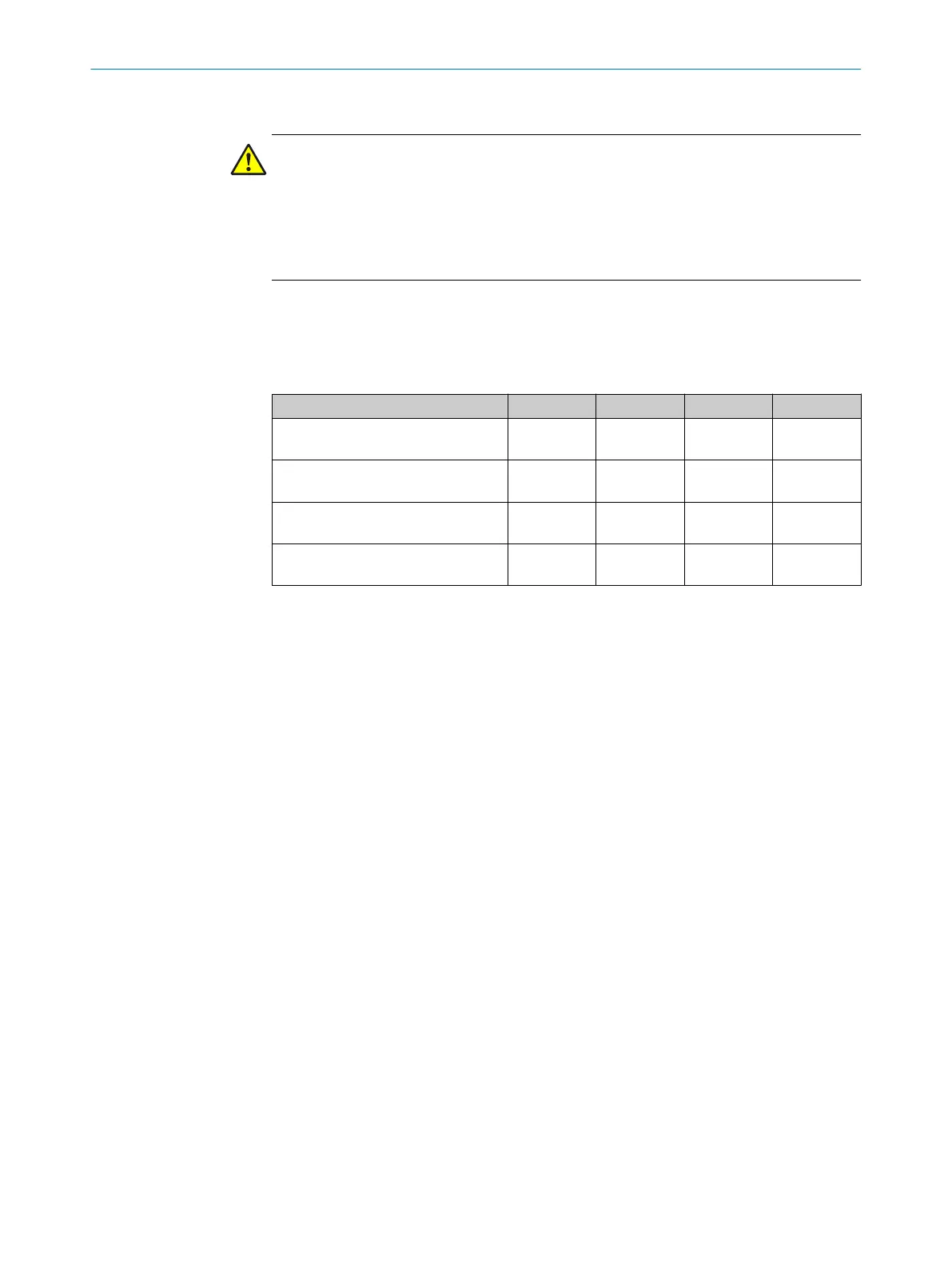

Configurable monitoring cases

T

he number of monitoring cases that can be configured depends on the variant and the

control. The following table shows the number of monitoring cases:

Table 23: Number of monitoring cases

Application Standard Advanced Professional Expert

Applications with local static control

in

puts on the safety laser scanner

1 4 8 8

Applications with static control inputs

via EFI (e.g., on a Flexi Soft)

32 32 32 32

Applications with dynamic control

in

puts on the safety laser scanner

– – 16 32

Applications with dynamic control

inputs via EFI

32 32 32 32

Complementary information

Y

ou can configure the monitoring cases in the CDS.

Each monitoring case includes the following information:

•

The input conditions, the so-called control signals that control the activation of the

monitoring case.

•

A field set comprising a protective field and warning field(s).

•

If necessary, a unique follow-on case or two alternative follow-on cases.

•

The multiple sampling for the field set.

Monitoring cases can be switched with the following input information:

•

Static information

•

Speed information

•

A combination of the two

Further topics

•

"Mount

ing", page 58

7.13.1 Monitoring case switching via static input information

Overview

F

or monitoring case switching via static input information, you configure for each moni‐

toring case the input condition to be used to switch to this monitoring case.

7 CONFIGURATION

94

O P E R A T I N G I N S T R U C T I O N S | S300 8010948/ZA21/2020-06-18 | SICK

Subject to change without notice

Loading...

Loading...