NCK start-up

10.6 Parameterization of spindle data

CNC Part 1 (NCK, PLC, drive)

Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

165

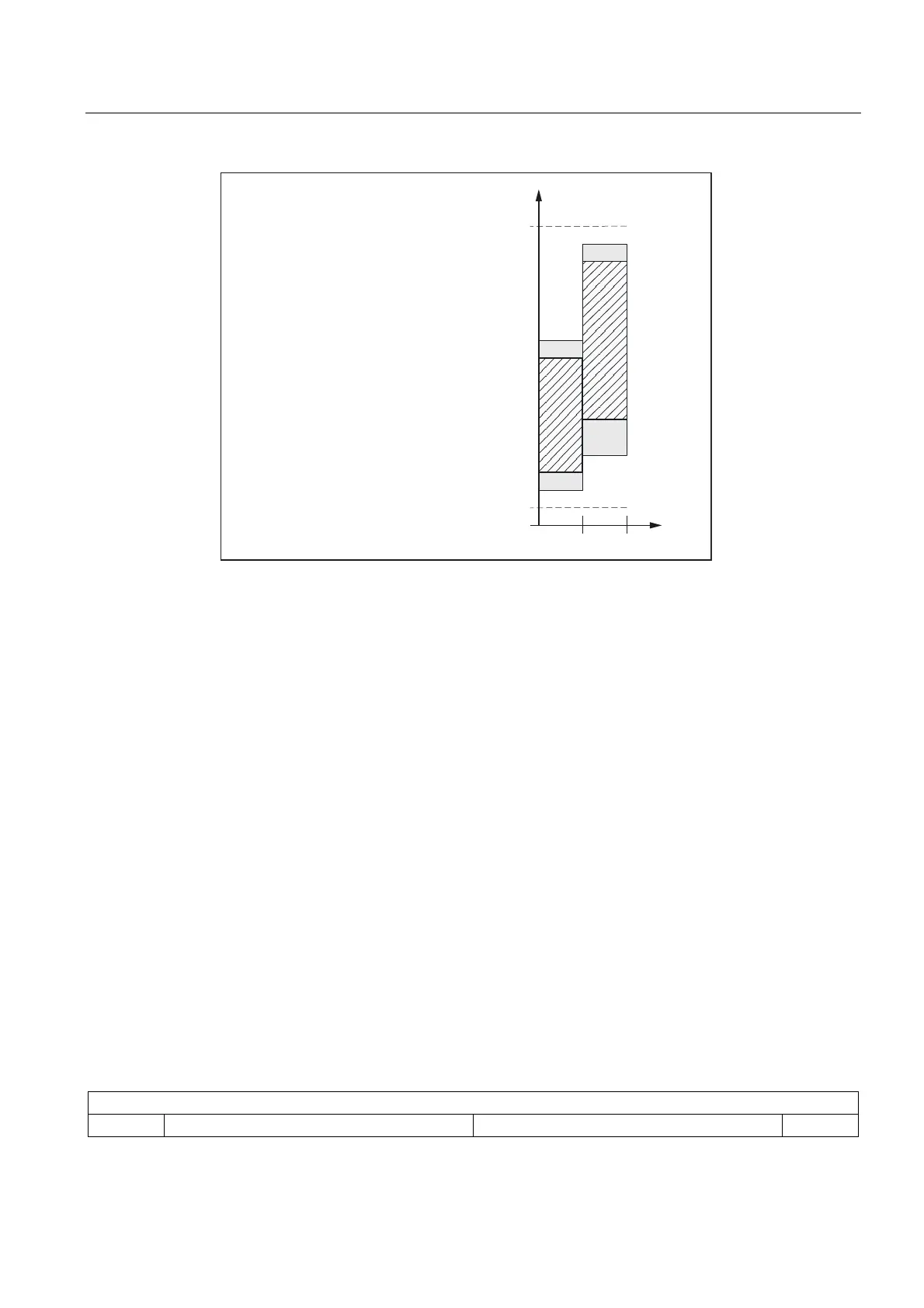

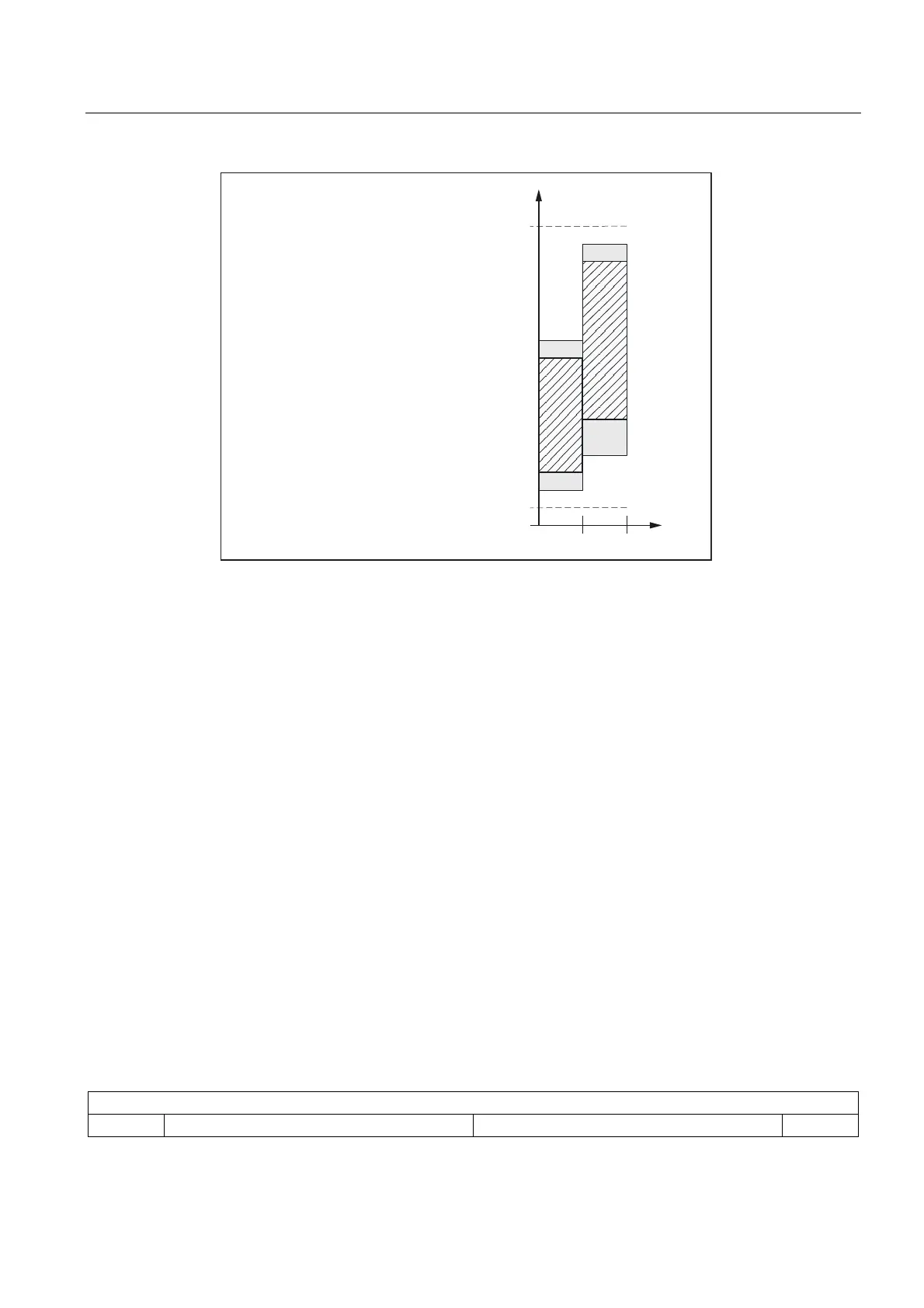

*HDUVWDJH

0LQVSLQGOHVSHHG

0LQLPXPVSHHGIRUJHDUVWDJH

0LQLPXPVSHHGIRUJHDUFKDQJH

0LQLPXPVSHHGIRUJHDUVWDJH

0LQLPXPVSHHGIRUJHDUFKDQJH

0D[LPXPVSHHGIRUJHDUFKDQJH

0D[LPXPVSHHGRIJHDUVWDJH

0D[LPXPVSHHGIRUJHDUFKDQJH

0D[LPXPVSHHGRIJHDUVWDJH

0D[LPXPVSLQGOHVSHHG

6SLQGOHVSHHG

UHYPLQ

Figure 10-21 Example for speed ranges for automatic gear stage selection (M40)

Speeds for conventional operation

The speeds of the spindle in conventional mode are entered in the machine data:

• MD32010 JOG_VELO_RAPID (rapid traverse in jog mode)

• MD32020 JOG_VELO (JOG axis velocity)

The direction of rotation is specified via the appropriate directional keys for the spindle on the

MCP.

Direction of rotation

The direction of rotation of a spindle corresponds to the traversing direction of an axis.

Setpoint matching

The speeds must be transferred with standardized values for the drive controller. The values

are scaled in the NC using the selected load gear and the appropriate drive parameter.

Machine data

Table 10-27 Speeds and setpoint adjustment for spindle: Machine data

Axisspecific ($MA_ ... )

31050 DRIVE_AX_RATIO_DENOM Load gearbox denominator G2

Loading...

Loading...